Digital holographic microscopic imaging method based on surface plasma resonance and microscope

A surface plasmon, digital holographic microscopy technology, applied in microscopes, optics, polarization influence characteristics, etc., can solve the problems of inconvenient digital holographic microscopy imaging, large compression distortion of the image plane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

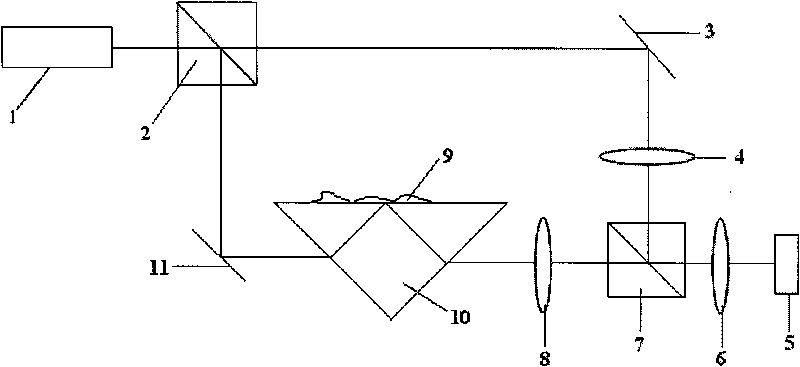

Method used

Image

Examples

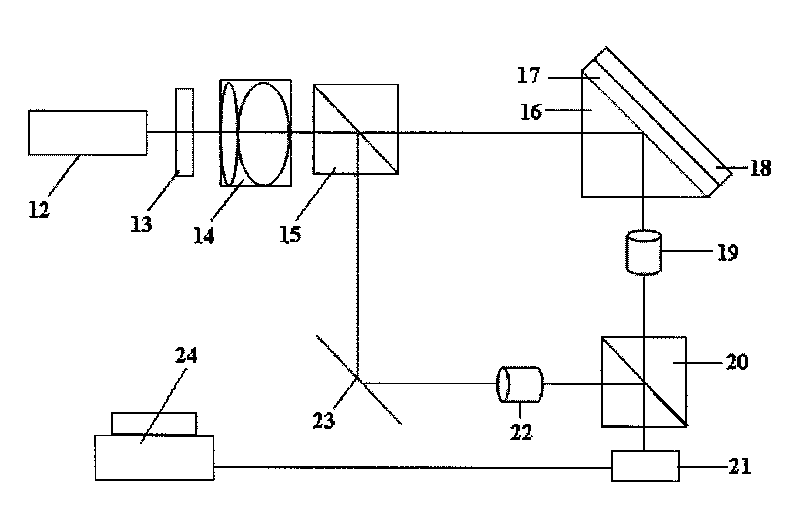

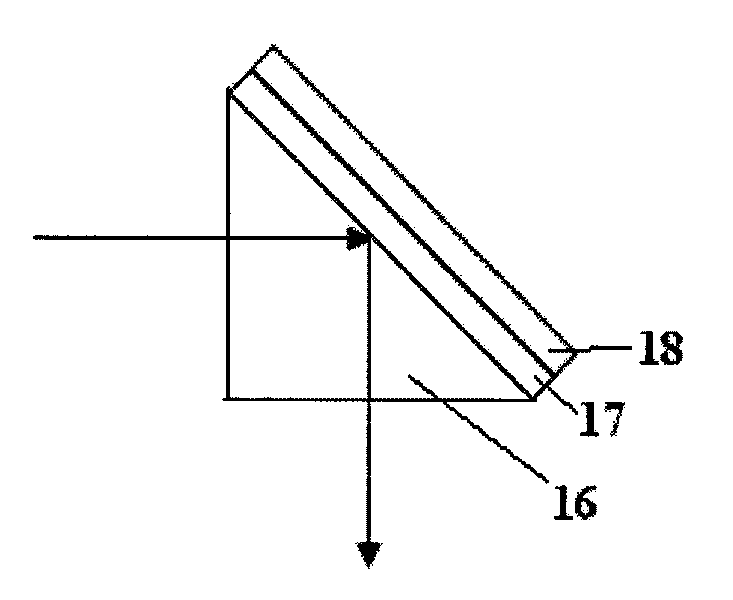

Embodiment

[0054] The laser 12 has an output power of 3mW and a wavelength of The linearly polarized He-Ne laser first adjusts its polarization direction to the P direction of the metal-coated film surface of the relative prism 16 (that is, the polarized light is incident on the metal-coated film surface of the prism 16, and its polarization direction is parallel to the incident surface). Linearly polarized helium-neon laser, so no additional polarizer is needed; the beam expander collimator 14 is composed of a pinhole filter and a collimator lens; the beam splitter 15 and the beam combiner 20 adopt a beam splitting ratio of 1: Depolarization beam splitting prism; Prism 16 is K9 glass 45 degree right angle prism, is plated with 50nm thick gold film on the cover glass of a K9 glass, covers glass is pasted on 45 degree right angle prism bottom surface with cedar oil; Mirror 23 is Plane reflection mirror; objective light microscope objective lens 19 and reference light microscope objective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com