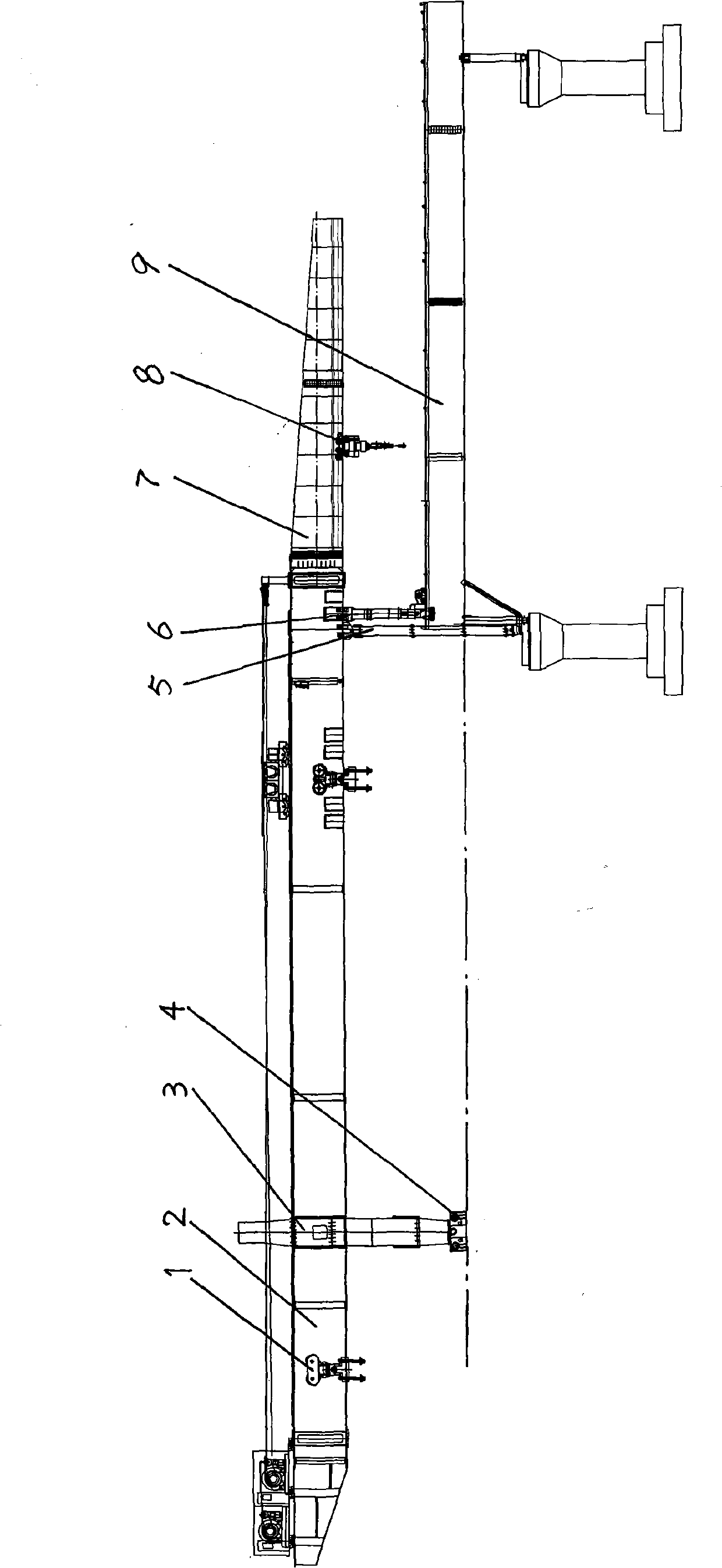

Bridge erecting machine for small-curve railway box girder

A small curve, bridge erecting machine technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems that cannot meet the requirements of small curve railway box girder erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

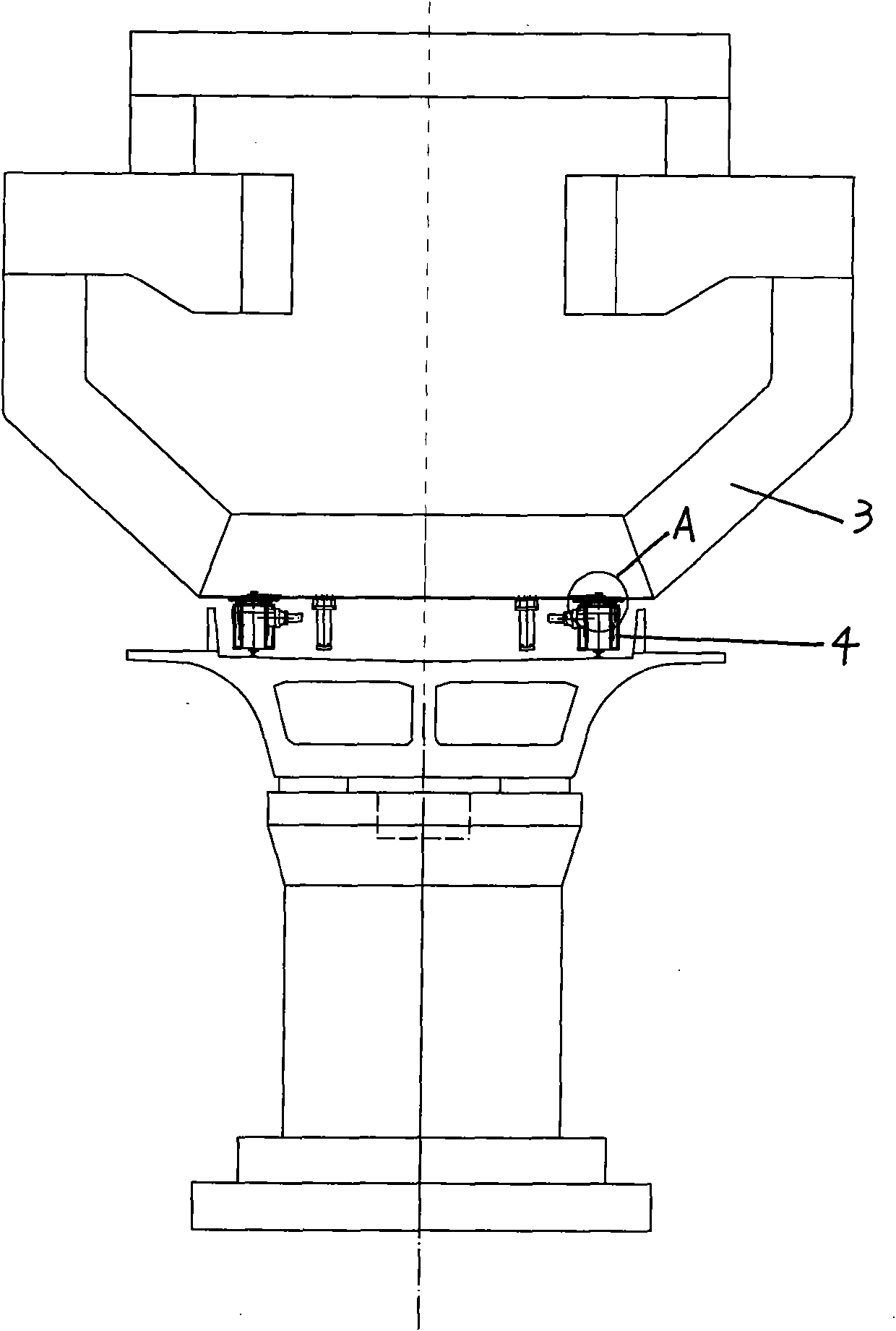

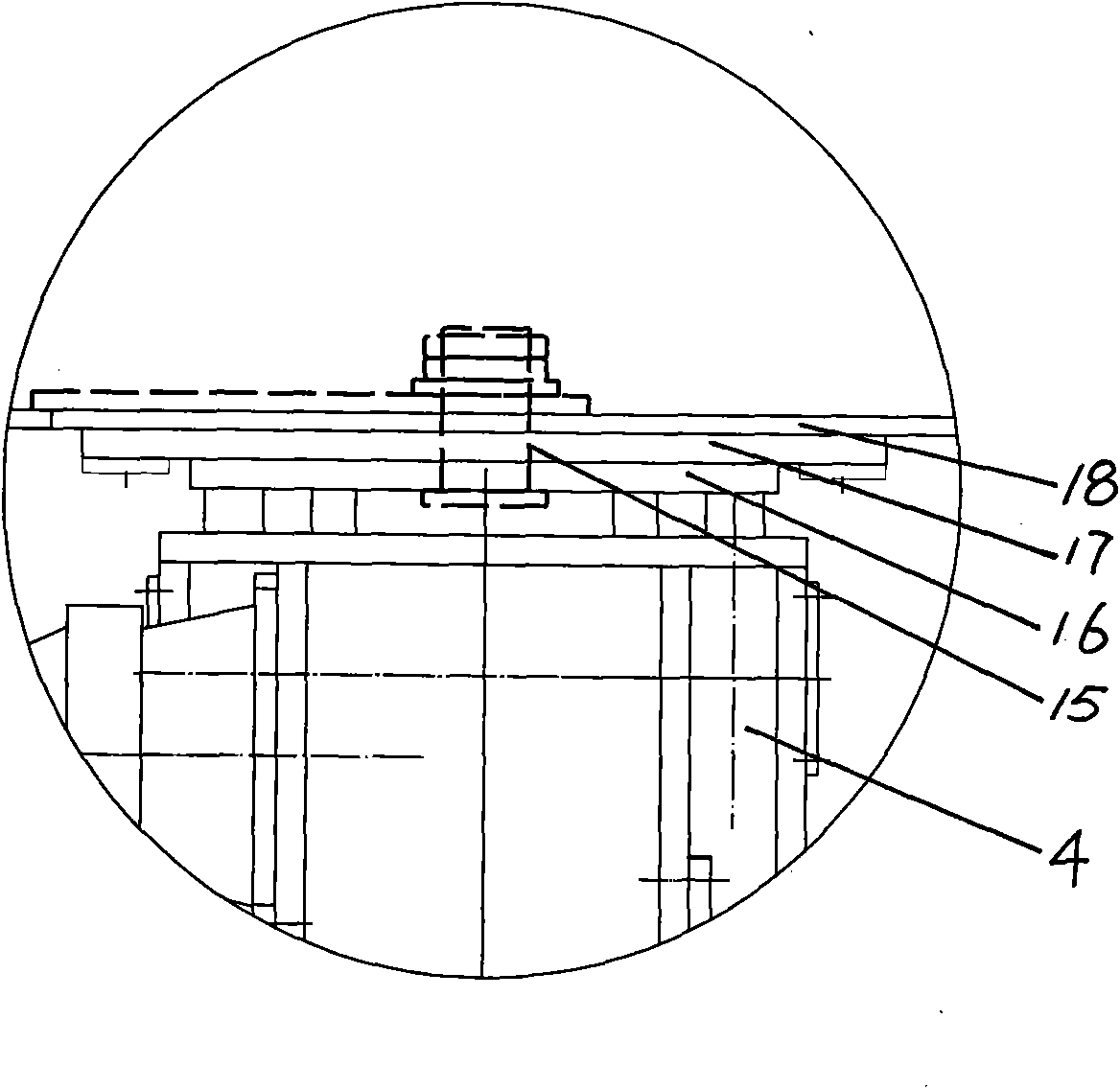

[0023] Embodiment 1: If erecting the R1200 meter curve radius bridge calculation on the spot: the distance S=21m between the dolly lifting point and the center of rotation, the lateral displacement δ of the dolly is ± 0.57m, and the width of the laterally moving rail frame is at least 4.5m (structure control).

[0024] The left running speed of the rear outrigger is 2.98m / min, and the right running speed of the rear outrigger is 3m / min. Just adjust the output frequency of the left frequency converter 1UA of the rear outrigger to 49.8HZ, and the output frequency of the right frequency converter 1UB of the rear outrigger Adjust the frequency to 50HZ to realize the differential operation of the rear outriggers and complete the curve erection of the bridge machine.

Embodiment 2

[0025] Embodiment 2: If erecting 500 meters of curved radius bridges on the spot, calculate: the distance S=21m between the lifting point of the trolley and the center of rotation, the lateral movement δ of the trolley is ±1.37m, and the width of the laterally moving rail frame is at least 6m.

[0026] The left running speed of the rear outrigger is 2.96m / min, and the right running speed of the rear outrigger is 3m / min. Just adjust the output frequency of the left inverter 1UA of the rear outrigger to 49.4HZ, and the output frequency of the right inverter 1UB of the rear outrigger Adjust the frequency to 50HZ to realize the differential operation of the rear outriggers and complete the curve erection of the bridge machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com