Steel plate hot forming method based on anti-oxidation coating and production line for implementing same

A hot forming and anti-oxidation technology, which is applied in the field of steel plate hot forming and hot forming production line based on anti-oxidation coating, can solve the problems of difficult precision, difficult cost, high price of atmosphere protection furnace, etc., achieve high temperature control accuracy and overcome heat conduction Poor performance, the effect of solving the problem of thermal processing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

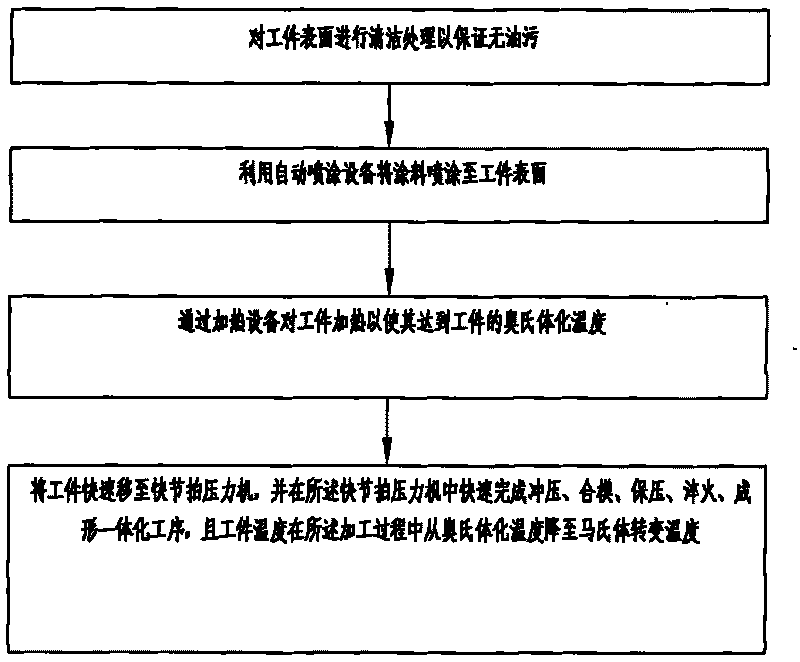

[0035] Now refer to the attached Figure 1-2 , the present invention is further described in conjunction with specific embodiments:

[0036] figure 1 It is a flow chart of the thermoforming method based on automatic spraying involved in the present invention, the method includes the following steps: cleaning the surface of the workpiece to ensure no oil stains;

[0037] Utilize automatic spraying equipment to spray the paint to the surface of the workpiece, wherein the automatic spraying equipment includes a spray gun 5 that uniformly sprays the paint on the surface of the workpiece through a pressure device, a power supply that provides direct current for the spray gun 5, and a power supply for storing powder A powder feeder 3 for feeding the powder to the spray gun according to the process requirements, a heat exchanger 4 for cooling the spray gun 5 so as to prolong the service life of the spray gun 5, a pump for delivering working gas and powder feeding gas Air supply sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com