Roller in caterpillar mechanical travelling mechanism

A walking mechanism and crawler-type technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of large space occupation, high cost, and low assembly efficiency of rollers, and achieve high assembly efficiency, reduced quantity, and stable product quality reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

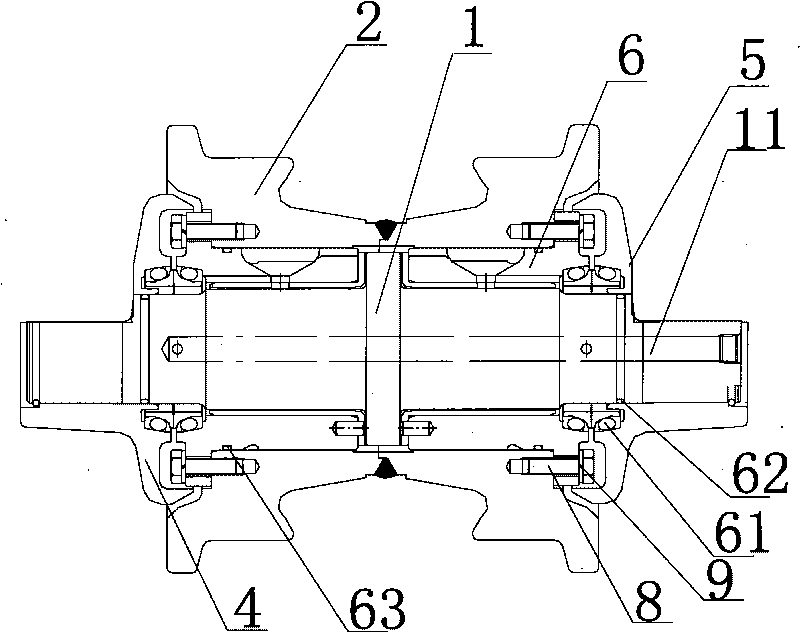

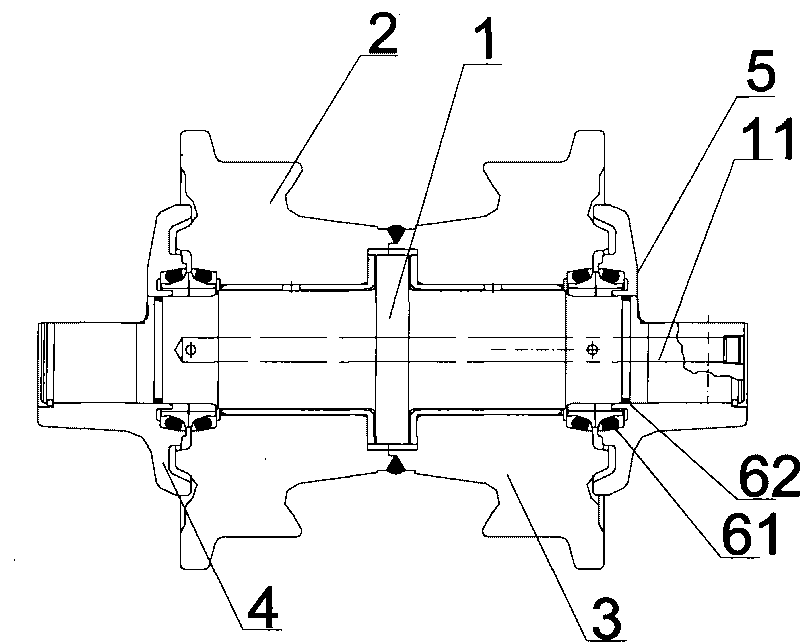

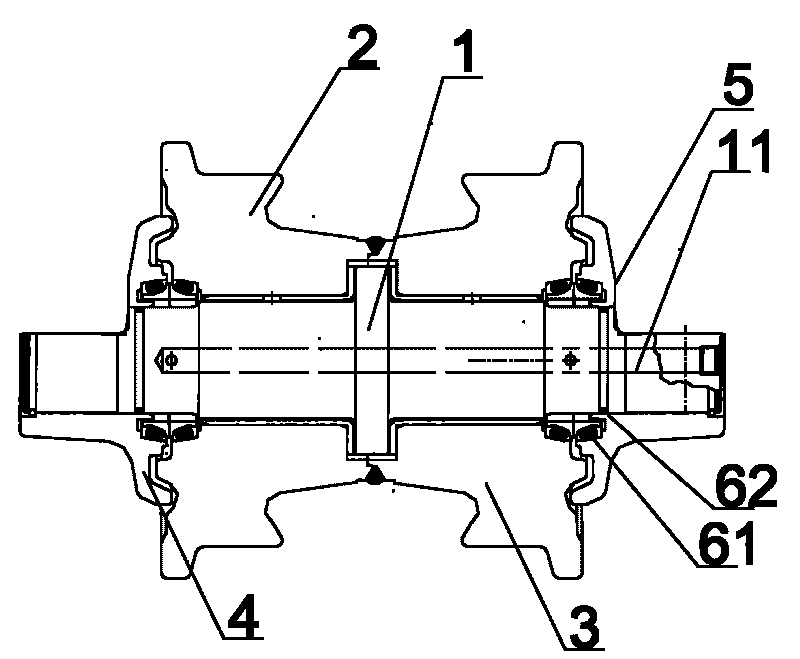

[0032] Example figure 2 As shown, the supporting wheels in the crawler-type mechanical traveling mechanism include a roller shaft 1 and a roller body 2 sleeved on the roller shaft 1, and a bushing 3 with bearing bushes is arranged between the roller body 2 and the roller shaft. The above-mentioned axle sleeve with the bearing bush is closely fitted and fixed with the outer roller body.

[0033] The bushing with bearing bush is a bimetallic bushing, the outer ring of the bushing and the roller body 2 are closel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com