Multi-point correcting method for bidirectional printing ink drop offset of broad width ink jet printer

An inkjet printer and two-way printing technology, which is applied to printing devices, printing, transfer materials, etc., can solve the problems of large manpower and material resources for installation, affect equipment put into use, and difficulty in equipment maintenance and maintenance in the later stage, so as to reduce manual correction Effects of workload, installation cost reduction, and sensitivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The multi-point correction method for bidirectional printing of the wide-format inkjet printer of the present invention will be described in detail below in conjunction with the accompanying drawings.

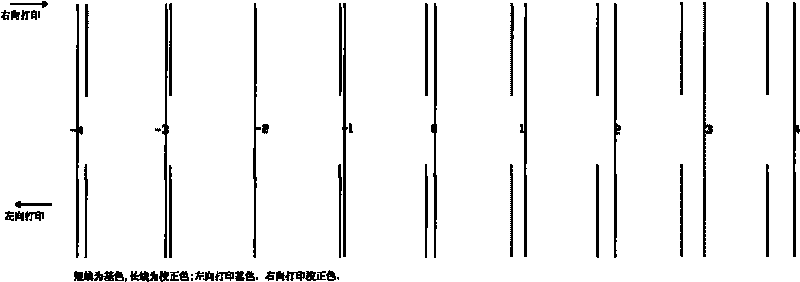

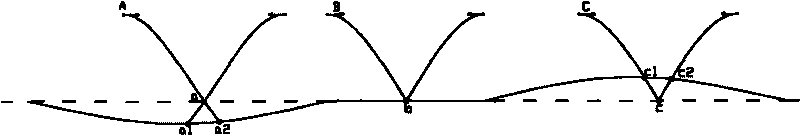

[0020] When implementing the multi-point correction method of the present invention, at first, as Figure 4 As shown, four calibration points S1, S2, S3, and S4 are selected at intervals along the length direction of the printing platform of the printer, and conventional two-way calibration maps are printed at the four points respectively, to obtain Figure 5 The 4 single-dot bi-directional printing correction charts shown in , the short line is the base color and the long line is the correction color, the base color is printed to the left and the correction color is printed to the right, and the correction values of 4 points are obtained from the figure, among which, the correction value of S1 is -1, the correction value of S2 is -4, the correction value of S3 is -2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com