Recovery processing method for hydrocarbon-contained waste gas

A technology for recycling and waste gas, which is applied in the field of recycling and processing, and can solve the problems of long process flow, economic impact, and economic decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

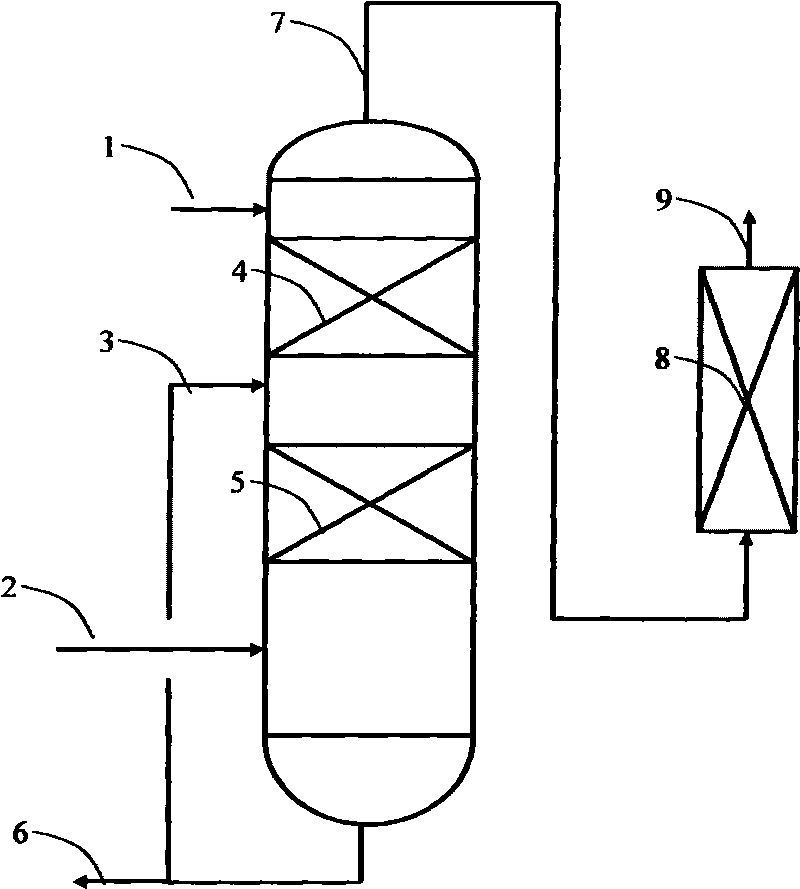

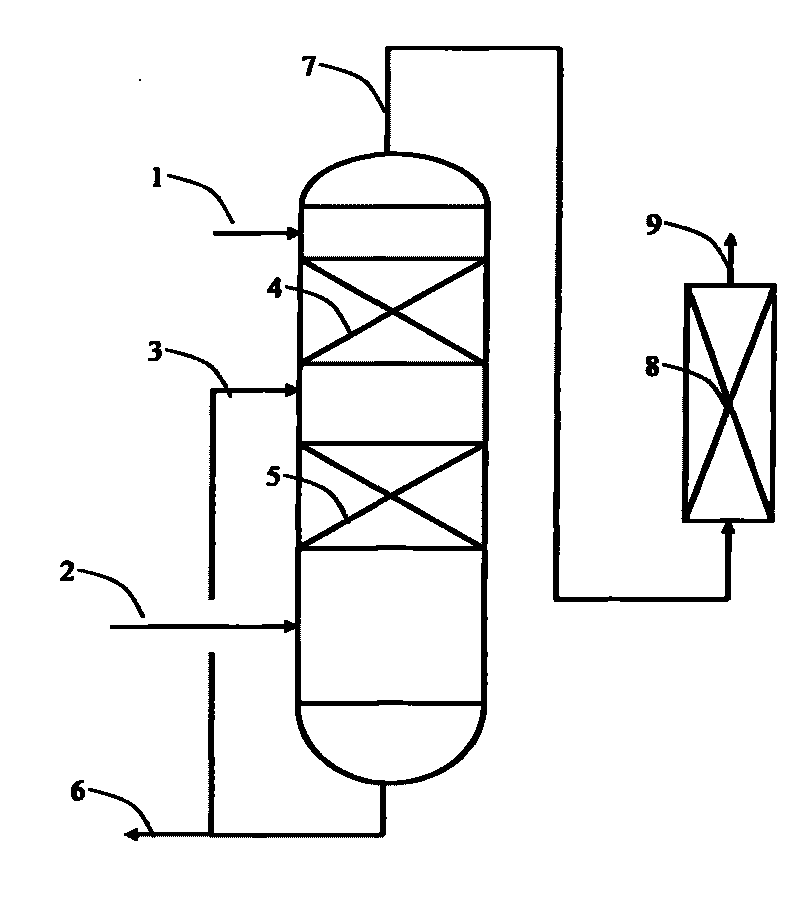

[0017] A certain gasoline oxidative sweetening tail gas and liquid hydrocarbon oxidative sweetening tail gas, the temperature is about 40°C, and the total hydrocarbon concentration is 30×10 4 ~80×10 4 mg / m 3 . The packed tower with two-stage packing is used, the packing is Φ25mm×25mm×6mm stainless steel Pall ring packing, and the volume ratio of the upper packing and the lower packing is 3:1.

[0018] The fresh diesel oil is normal second-line diesel oil with an initial boiling point of 200°C. It comes from the fractionation tower of the refinery unit at a temperature of 60°C. After heat exchange and cooling to 8°C, it enters the packed tower. The designed volume ratio of fresh diesel oil to the exhaust gas at the inlet of the packed tower is 0.08 (due to large fluctuations in exhaust gas flow during operation, the ratio also fluctuates in a large range), the amount of circulating diesel oil is 4 times the volume of fresh diesel oil, and the design value of the volume flow s...

Embodiment 2

[0024] A gas oil storage tank area and a waste oil tank area discharge exhaust gas, the temperature is about 40°C, and the total hydrocarbon concentration is 9×10 4 ~40×1 0 4mg / m 3, the sulfide concentration is 1000mg / m 3 about. First use sodium hydroxide solution to absorb and remove sulfide, after the sodium hydroxide solution absorbs, the sulfide concentration is lower than 10mg / m 3 , and then carry out distillate oil absorption-activated carbon adsorption treatment. Distillate oil absorption adopts a packed tower with two-stage packing. The packing is Φ25mm×25mm×6mm stainless steel Pall ring packing. The volume ratio of the upper packing and the lower packing is 1:1.

[0025] The fresh distillate oil is heavy naphtha with an initial boiling point of 90°C. It comes from the fractionation tower of the refinery unit at a temperature of 40°C. After heat exchange and cooling to -20°C, it enters the packed tower. The fresh heavy naphtha and the exhaust gas at the inlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com