Flame filter

A filter and flame technology, applied in fire rescue, machine/engine, mechanical equipment, etc., can solve the problems of injection flame, deformation, no longer provide explosion relief valve, etc., to achieve the effect of small processing consumption and small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

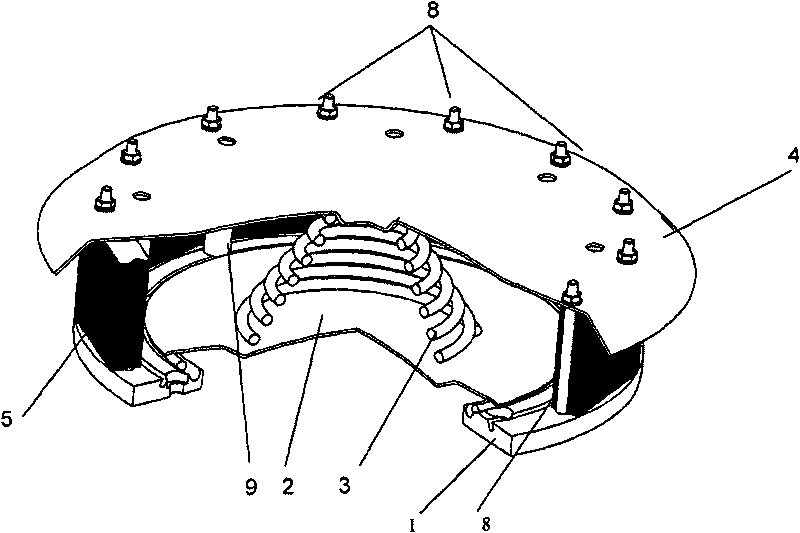

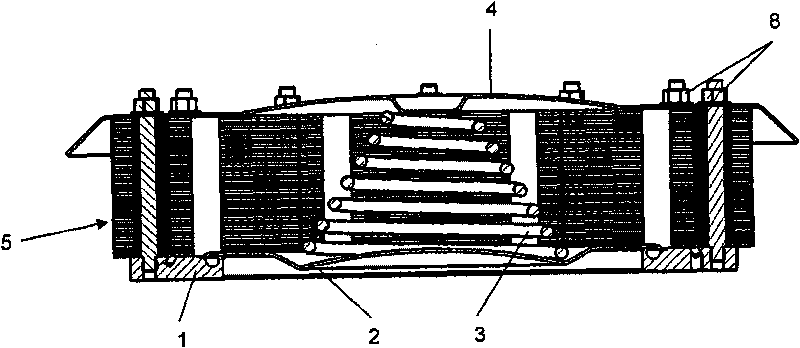

[0026] figure 1 and 2 shows an explosion relief valve, as it is used, for example, in diesel and gas engines of marine machines and power plants. There they are installed in the crankcase or in the system wall in order to be able to dissipate excess pressure in the event of, in particular, gas and / or oil mist explosions and thus avoid damage to the engine or system. The valve comprises an annular valve seat 1 which is fastened to an opening in the crankcase wall by means of screws or the like. Cooperating with the valve seat 1 is a closing plate 2 which is acted upon by a helical compression spring 3 which is preferably conically wound. The valve passes upwards through a catcher 4 designed as a cover plate with an edge region bent towards the crankcase. Covering, wherein the helical compression spring 3 is also supported on the catcher 4 . A sealing ring (not shown) inserted into the groove of the valve seat 1 ensures a tight seal in the closed position of the valve.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com