Purple corn beverage and preparation method thereof

A technology of purple corn and beverages, which is applied in the field of food and beverages, can solve the problems of easy fading and poor stability of anthocyanins, etc., and achieve the effect of increasing nutrients, enriching flavor, and improving taste and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

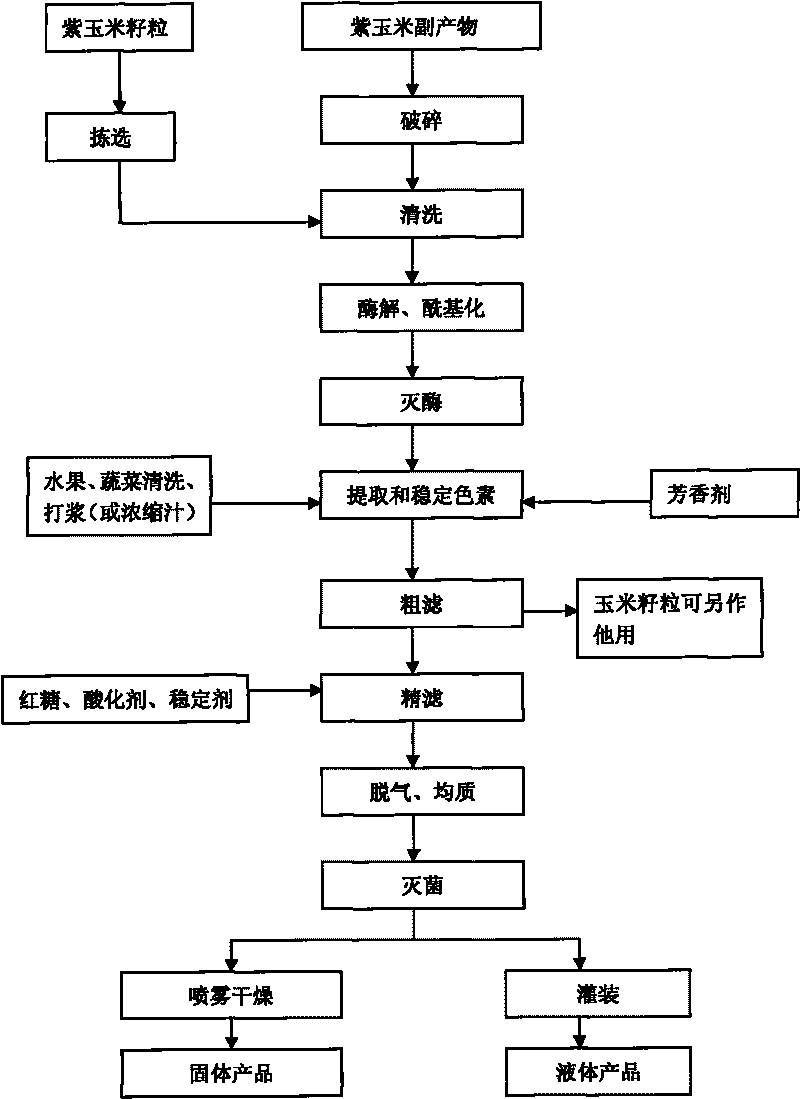

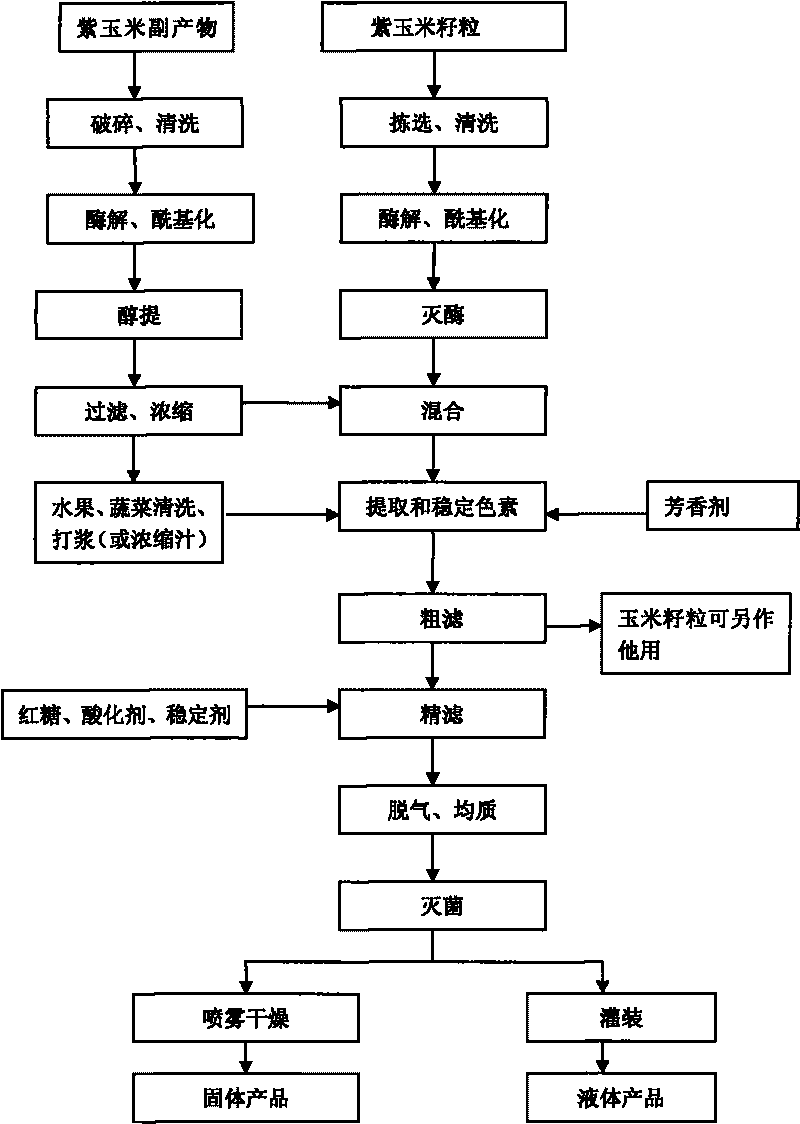

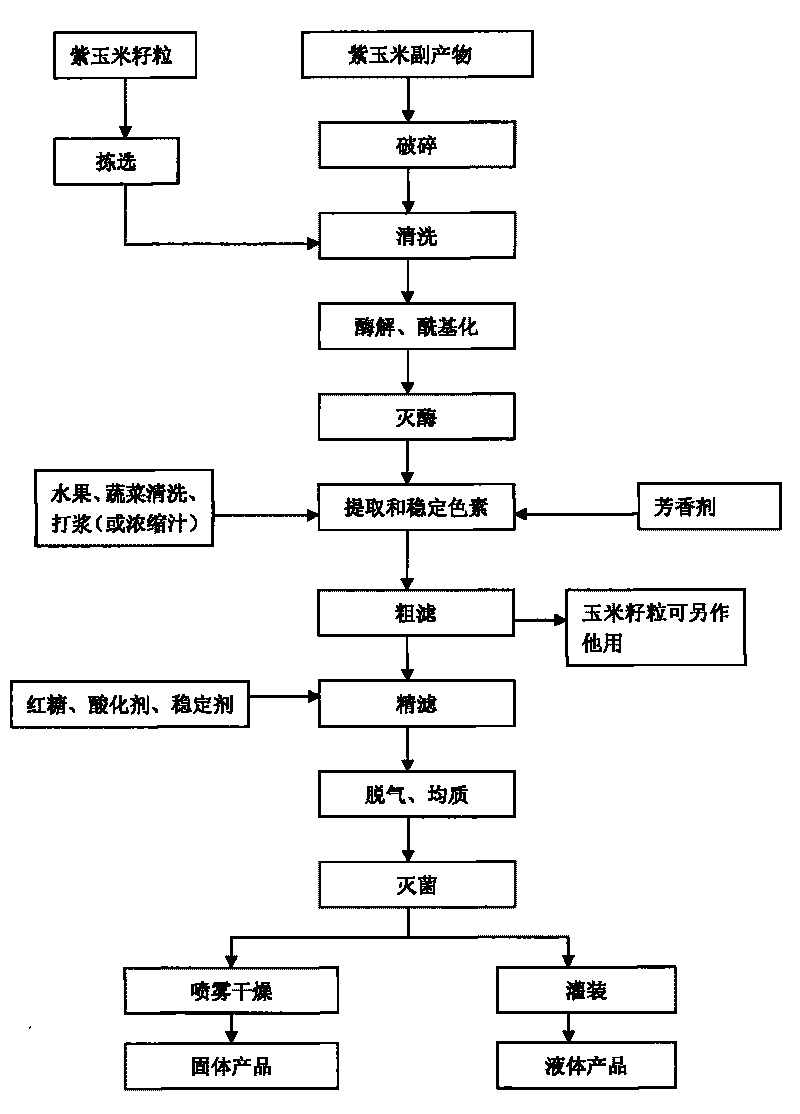

Method used

Image

Examples

Embodiment 1

[0074] Raw material formula:

[0075] Purple corn kernels 200g

[0076] Purple corn by-product 200g

[0077] Compound fruit 200g

[0078] 10g compound spices

[0079] Brown sugar 80g

[0080] Stabilizer 10g

[0081] Acidulant 1.5g

[0082] 2000g water for soft drinks

[0083] Enzyme preparation 4 grams

[0084] Acylating agent 3 grams

[0085] Production process of liquid purple corn compound beverage:

[0086] 1. Purple corn grains: choose 200 grams of dry grains with good maturity, no pests and mildew, and it is better if they can be soaked for 3-4 hours before processing;

[0087] 2. By-products of purple corn (bracts, leaf sheaths, cobs, filaments, taken at random): 200 grams of dry raw materials without mildew and disease are selected and crushed into 5cm 2 About size;

[0088] 3. Cleaning: Clean the purple corn grains and purple corn by-products to remove dust and impurities and mix them;

[0089] 4. Enzyme treatment and acylation: add about 1000 grams of sof...

Embodiment 2

[0099] Raw material formula:

[0100] Purple corn kernels 200g

[0101] Purple corn by-product 200g

[0102] 100g vegetable juice

[0103] Spices 7g

[0104] Brown sugar 100g

[0105] Stabilizer 10g

[0106] Acidulant 3 grams

[0107] 2000g water for soft drinks

[0108] Enzyme preparation 4 grams

[0109] Acylating agent 3 grams

[0110] The production process of solid purple corn compound beverage:

[0111] 1. Purple corn grains: choose 200 grams of dry grains with good maturity, no pests and mildew, and it is better if they can be soaked for 3-4 hours before processing;

[0112] 2. Purple corn by-products (bracts, leaf sheaths, cobs, filaments, etc., selected at random): 200 grams of raw materials without mildew and disease are selected and crushed into 5cm 2 About size;

[0113] 3. Cleaning: Clean the purple corn grains and purple corn by-products to remove dust and impurities and mix them;

[0114] 4. Enzyme treatment and acylation: Add about 1000 grams of sof...

Embodiment 3

[0125] Raw material formula:

[0126] Purple corn kernels 200g

[0127] Purple corn by-product 400g

[0128] Goji berry juice 200g

[0129] 18g compound spices

[0130] Stabilizer 12g

[0131] Acidifier 5 grams

[0132] 120g brown sugar

[0133] 3000 grams of water

[0134] Enzyme preparation 6 grams

[0135] Acylating agent 5 grams

[0136] Production process of liquid purple corn compound beverage:

[0137] 1. Extraction of active ingredients of purple corn by-products:

[0138]The by-products of purple corn (bracts, leaf sheaths, cobs, filaments, etc., taken at random) are selected from 400 grams of raw materials without mildew and disease, and crushed into 5cm 2 Size or so. Soak the crushed raw materials in about 1000ml of water, heat to 50-55°C, add 4 grams of compound enzyme preparation (cellulase and hemicellulase, the mass ratio of the two is 1:1), and add 3 grams of acetic acid at the same time carry out acylation. After heating for 30 minutes, heat up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com