Environment-friendly microbial fermentation non-polluted liquid-state feed and production method thereof

A technology of microbial fermentation and liquid feed, applied in the field of animal husbandry, can solve the problems of complex production process, decreased feed economy, and inability to be widely used, so as to improve feed remuneration, increase livestock weight quickly, and improve disease resistance. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

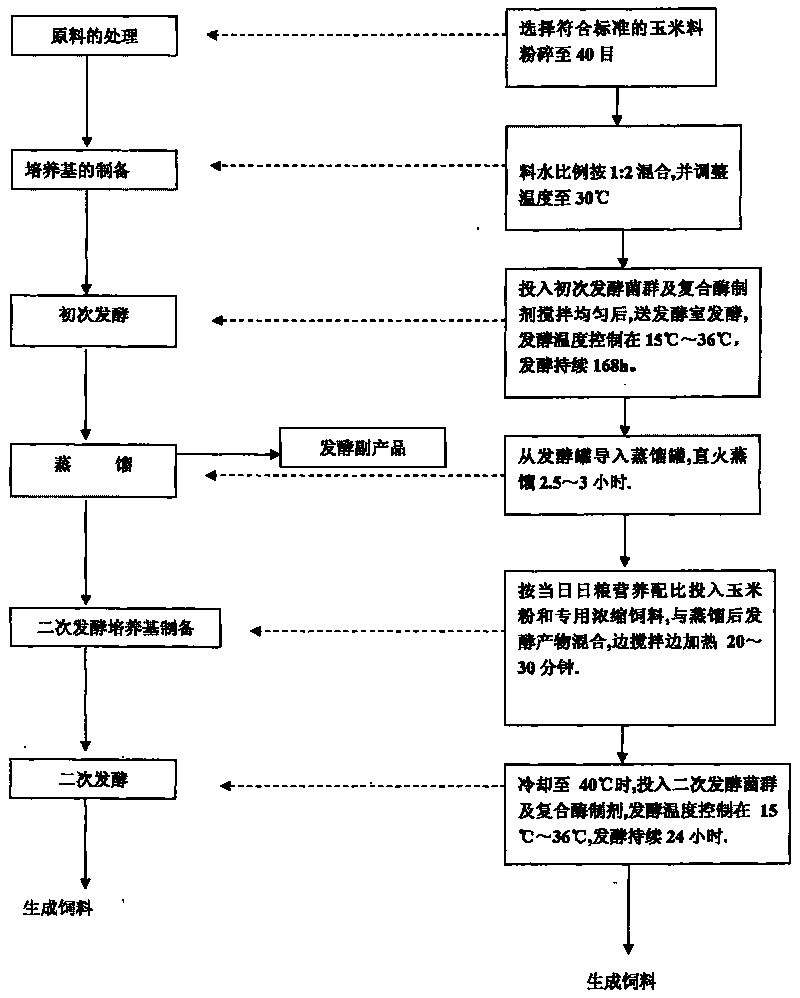

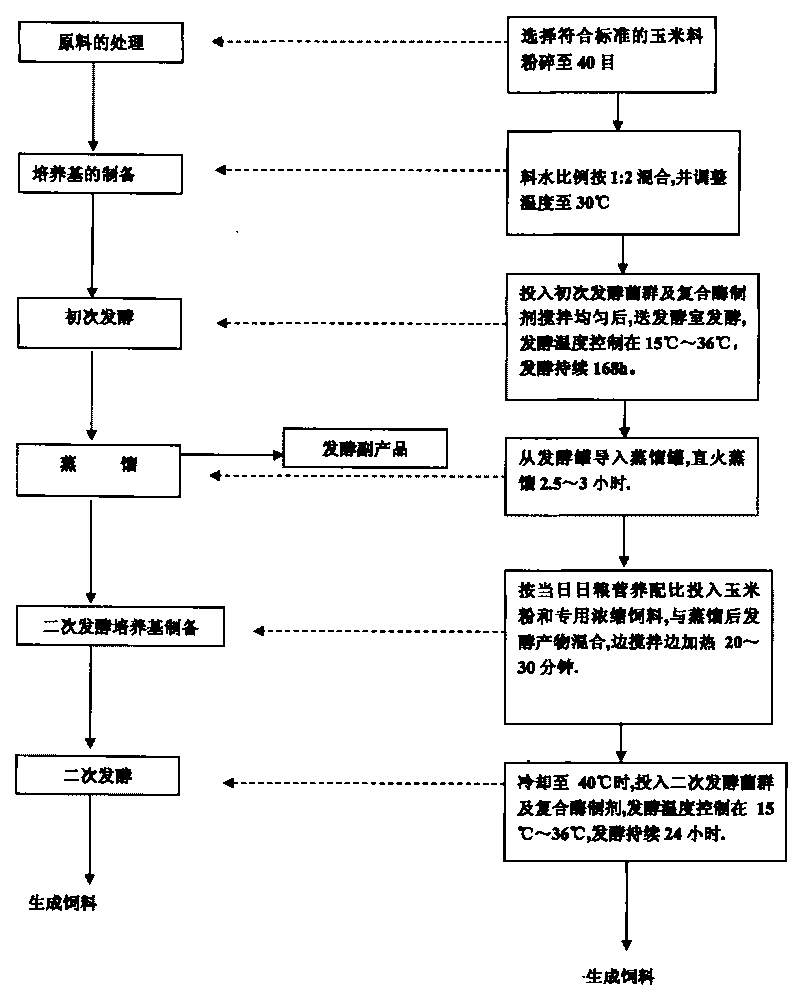

Method used

Image

Examples

Embodiment 1

[0018] Environment-friendly microbial fermentation pollution-free liquid feed, its composition includes: energy feed raw materials, protein feed raw materials, minerals, vitamins, amino acids, probiotic flora and compound enzyme preparations, the energy feed raw materials are 65 kg, the 22.5 kg of protein feed material, 1.2 kg of minerals, 0.163 kg of vitamins, 0.1 kg of amino acids, and 1.5×10 probiotic flora -4 kg and the compound enzyme preparation is 3×10 -4 Kilogram.

Embodiment 2

[0020]Environment-friendly microbial fermentation pollution-free liquid feed, its composition includes: energy feed raw materials, protein feed raw materials, minerals, vitamins, amino acids, probiotic flora and compound enzyme preparations, the energy feed raw materials are 77 kg, the The protein feed material is 29.5 kg, the mineral is 1.4 kg, the vitamin is 0.178 kg, the amino acid is 0.15 kg, and the probiotic flora is 1.5×10 -4 kg and the compound enzyme preparation is 3×10 -4 Kilogram.

Embodiment 3

[0022] The above-mentioned environmentally friendly microbial fermentation pollution-free liquid feed, the energy feed raw materials include 63 kg of corn and 2 kg of soybean oil in parts by weight; the protein feed materials include 13 kg of soybean meal in parts by weight, bacterial protein 9.2 kg; the minerals include 0.3 kg by weight of table salt, 0.9 kg of calcium and phosphorus supplements and 0.085 kg of trace element supplements; Fungi 6×10 -5 Kg, primary fermentation components Bacillus 1×10 -5 kg, secondary fermentation components yeast 2 × 10 -5 kg and secondary fermentation components Bacillus 4 × 10 -5 kg; the compound enzyme preparation comprises glucoamylase 7.5×10 in parts by weight ratio of the primary fermentation component -5 kg, primary fermentation component protease 2×10 -5 kg, primary fermentation component cellulase 2×10 -5 kg, primary fermentation component phytase 2×10 -5 kg, primary fermentation component pectinase 2×10 -5 kg, secondary ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com