Light anode and flexile solar battery thereof

A solar cell and photoanode technology, applied in photovoltaic power generation, circuits, capacitors, etc., can solve the problems of easy recombination, long transmission path, large contact resistance, etc., to improve charge transmission efficiency, improve conversion efficiency, and reduce contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] According to a first embodiment of the present invention, a method for preparing a photoanode for a flexible solar cell is provided, comprising the following steps:

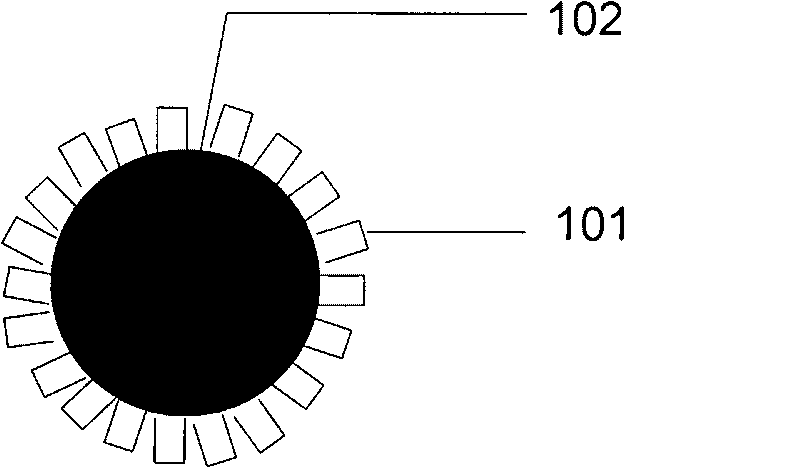

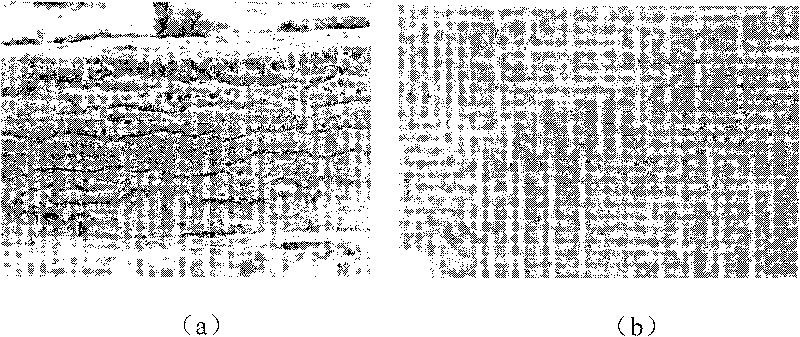

[0035] Step 1): Clean the pure titanium wire (purity ≥ 99.7%) with a length of 4 cm and a diameter of 0.3 mm in acetone and ethanol for 30 minutes, then take it out and dry it in the air; put the part of the titanium wire about 3 cm in length Put into the electrolytic solution that contains fluorine ion and carry out anodic oxidation, wherein the electrolytic solution that contains fluorine ion is the ethylene glycol solution that is 0.2% NH4F by weight (adding the deionized water that volume ratio is 1%), during anodic oxidation For the titanium wire obtained in step 1), the cathode is carbon, and the two electrodes are placed oppositely and in parallel with a distance of 3-5cm, the applied voltage is a DC constant voltage of 40V, and the anodic oxidation time is 3-5 hours, and the grown organic TiO 2 Ti...

Embodiment 2

[0045] The photoanode is prepared according to the method of Example 1, the difference is that in step 3) the obtained sample is put into the deposition solution of CdSe quantum dots for several hours, that is, the method of chemical liquid phase deposition is used on TiO 2 CdSe quantum dots are deposited on the side walls of the nanotubes.

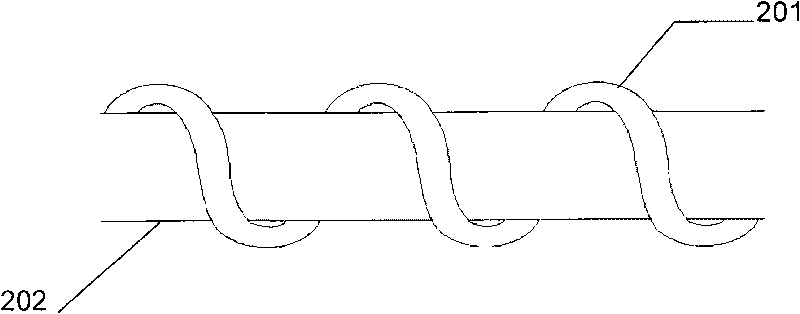

[0046] Take 0.1mm surface with Cu attached 2 The copper wire of S is used as the counter electrode. According to the battery assembly method in Example 1, the counter electrode and the photoanode grown with quantum dots are wound, and then the Na 2 The aqueous solution of S and S is used as electrolyte.

[0047] The fiber-shaped quantum dot sensitized battery was tested, and the short-circuit photocurrent can reach 8.5mA / cm 2 , open circuit voltage and fill factor were 653mV and 0.59, and its efficiency was 3.3%.

[0048] In the above technical solution, the quantum dots can also be other narrow bandgap semiconductor quantum dots, such...

Embodiment 3

[0050] Prepare the photoanode according to the method of Example 1, the difference is that the pure titanium wire with a diameter of 0.11 mm is taken, and the titanium wire is wound 5 times on the rectangular glass of 4 cm × 3 cm × 0.3 cm during anodic oxidation, and the distance between each circle is The spacing is 0.3 mm. After fixing the head and tail ends of the titanium wire, it is anodized again. Other steps are as in Example 1, so as to obtain TiO 2 Titanium filaments 502 of nanotubes juxtaposed, such as Figure 5 shown as a photoanode.

[0051] The above-mentioned photoanode and flat counter electrode are assembled into a flexible solar cell in the following manner: use sandpaper to polish the upper part 503 of the titanium wire 502 wound on the top of the glass 501, and then use a blade to polish the upper part 503 of the titanium wire 502 and the upper part 503 of the titanium wire 502. The lower part 204 is cut off, and the glass 501 is removed; as Image 6 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com