Textile industry industrial site Ethernet control system and method

A technology of industrial site and control system, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of inability to monitor work conditions in real time and accurately, waste of resources and manpower, and large human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

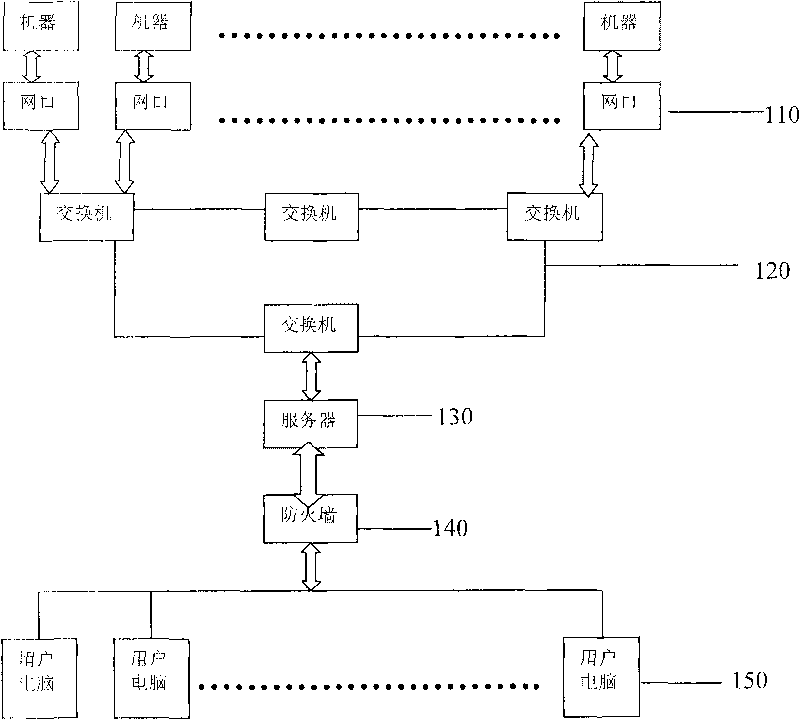

[0020] Such as figure 1 As shown, a network port 110 is set on each of the multiple machines in the textile industry site, and the network 110 is connected to the switch 120. In order to ensure the transmission speed of data, several machines use a switch 120, and then these switches 120 are connected in series to form a network. An integral switch 120; the switch 120 is connected to a server 130, the server 130 is connected to multiple user computers 150, and a firewall 140 is arranged in the middle.

[0021] Such as figure 2 As shown, firstly, the client (machine device) creates a socket (channel), that is, a channel for data transmission with the server, and then initiates a request to connect to the server according to the server's IP address and port number. At this time, when the server starts the program, it also creates a socket and a completion port, binds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com