Measurement circuit of direct current

A DC current and measurement circuit technology, applied in the direction of measuring electrical variables, measuring current/voltage, measuring devices, etc., can solve the problems of poor thermal stability, large zero drift, measurement error, etc., and achieve good temperature stability and large current range , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

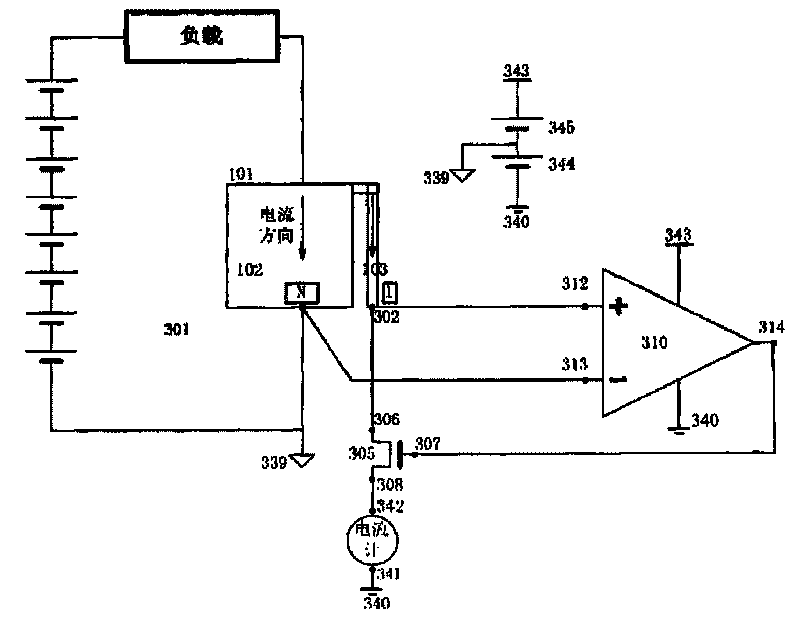

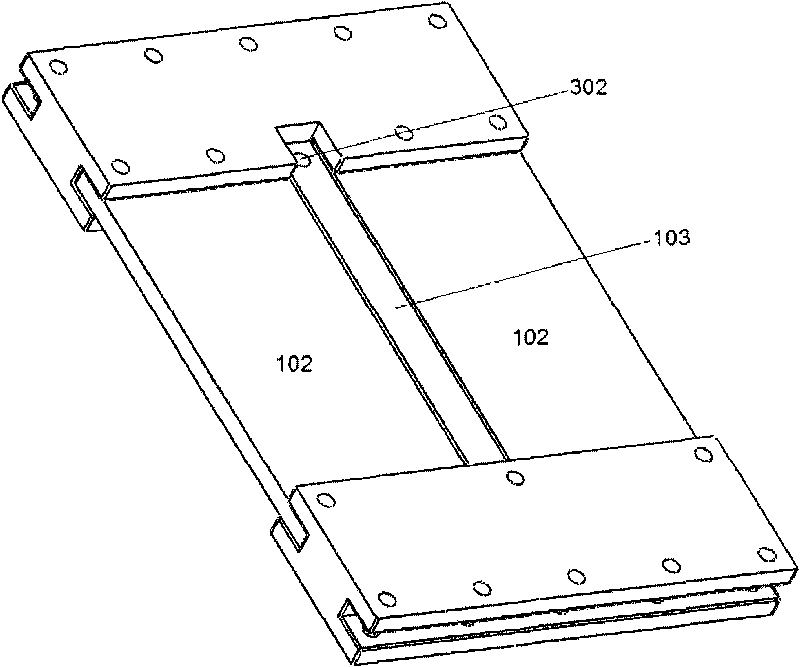

[0044] Such as figure 1 As shown, the direct current detection circuit of this embodiment includes a main circuit 301 of the direct current to be measured. In the direct current measurement circuit, the first conductor 102 is connected in series with the main circuit 301, and one end of the second conductor 103 is connected to the first A conductor 102 is connected, the resistance of the first conductor 102 is smaller than the resistance of the second conductor 103 , and the first conductor 102 and the second conductor 103 form a current conductor 101 with a bifurcated structure.

[0045] The other end 302 of the second conductor 103 is respectively connected to the drain 306 of the first field effect transistor 305 of the direct current measurement circuit and the positive voltage input terminal 312 of the operational amplifier 310;

[0046] The other end of the first conductor 102 is connected to the negative voltage input terminal 313 of the operational amplifier 310 of the...

Embodiment 2

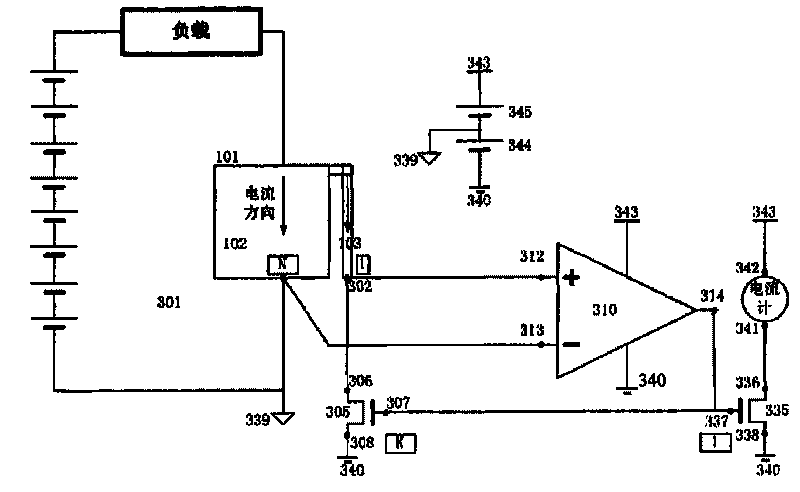

[0061] The second preferred embodiment of the present invention is improved on the basis of the above-mentioned preferred embodiment 1, such as figure 2 As shown, namely:

[0062] The source 308 of the first field effect transistor 305 is connected to the ammeter as the output terminal of the direct current measurement circuit and changed to: connect the grid 307 of the first field effect transistor 305 to the grid 337 of the second field effect transistor 335 connected; the source 338 of the second FET 335 is connected to the ground 340 of the direct current measurement circuit; its drain 336 is connected to one end 341 of the ammeter as the output end of the direct current measurement circuit; the other end of the ammeter 342 is connected to the positive pole 343 of the direct current measurement circuit.

[0063] In this way, the current flowing through the first field effect transistor 305, that is, the current flowing through the second conductor 103, passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com