Device and method for simultaneously monitoring flue gas particles and polluted gases on line

A technology for polluting gases and particulate matter, which is applied in the direction of measuring devices, particle suspension analysis, suspension and porous material analysis, etc., and can solve the problems of high maintenance costs, high cost, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

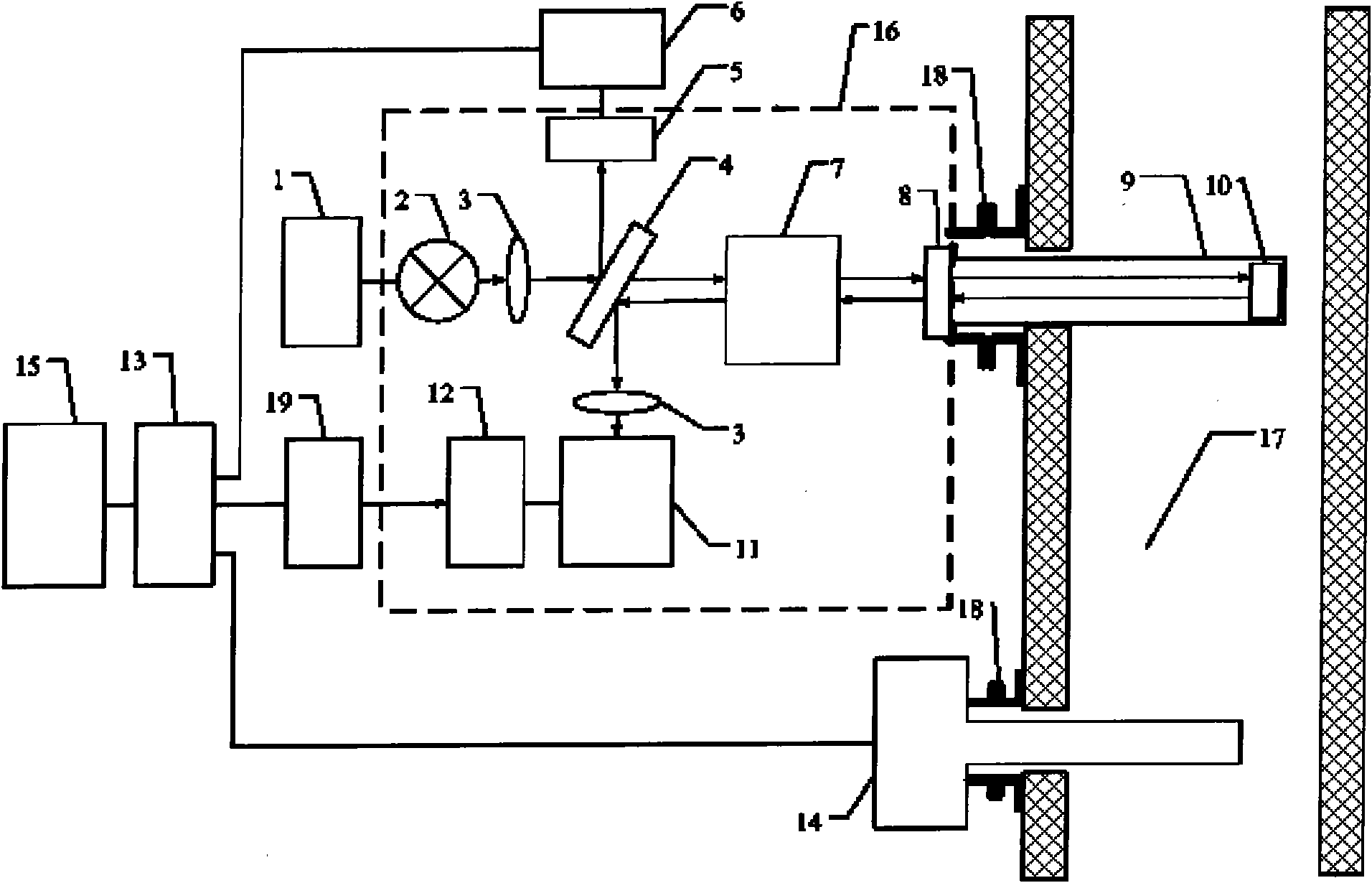

[0059] Such as figure 1 As shown, the present invention is a plug-in simultaneous online monitoring device for flue gas particulate matter and polluted gas. The spectrometer housing (16) is fixed to the flue (17) through the flange (18), and the flue gas emission parameter measurement unit (14) It is fixed with the flue (17) by the flange (18). The measurement signal of the flue gas emission parameter measurement unit (14) and the measurement signal of the spectrometer are connected to the AD converter (13) through a cable, and sent to the computer (15).

[0060] The light emitted by the light source (2) compresses the divergence angle through the lens (3), and is divided into two beams of light by the beam splitter (4). The preamplifier (6) is amplified and then sent to the AD converter to monitor and correct changes in the measured light intensity. The transmitted light of the beam splitter is collimated by the collimating mirror (7), and is incident on the flue (17) throu...

Embodiment 2

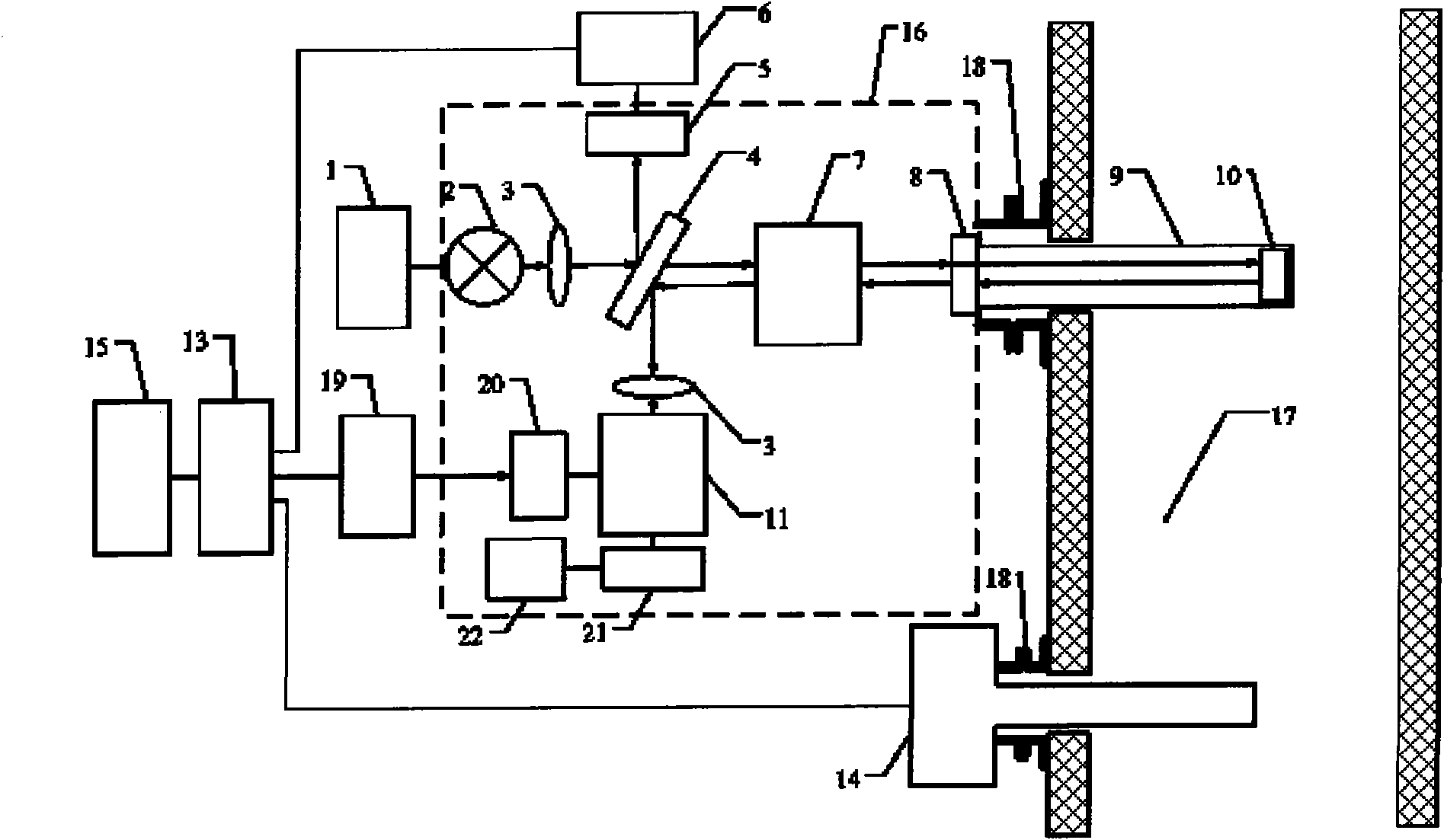

[0102] Such as figure 1 As shown, the present invention is a plug-in simultaneous on-line monitoring device for smoke particulate matter and polluted gas. The difference from Embodiment 1 is that in this embodiment, a planar grating is used as the dispersion element, and the measuring path detector (20) is used for single-channel signal detection, and the scanning of the dispersion wavelength is realized by the rotation of the grating driven by the micromotor (21) . The detector may be one of a photodiode, a photocell, and a photomultiplier tube. The micro motor (21) is driven by a micro motor driver (22).

[0103] Other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com