Concrete curing method for repairing cracks in winter in cold regions

A technology for repairing cracks and concrete, which is applied in earthwork drilling, building maintenance, road repair, etc. It can solve the problems that cracks in concrete structures cannot be repaired, and achieve the effect of stable and long-lasting hydration process, good fluidity and uniform maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

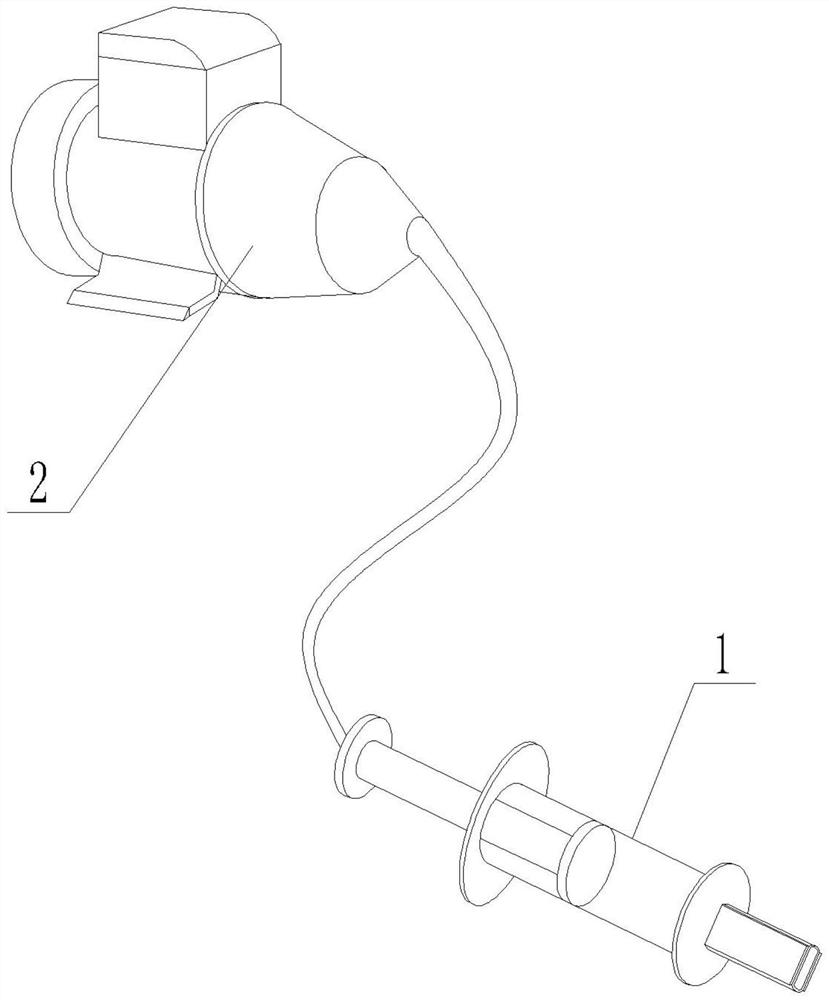

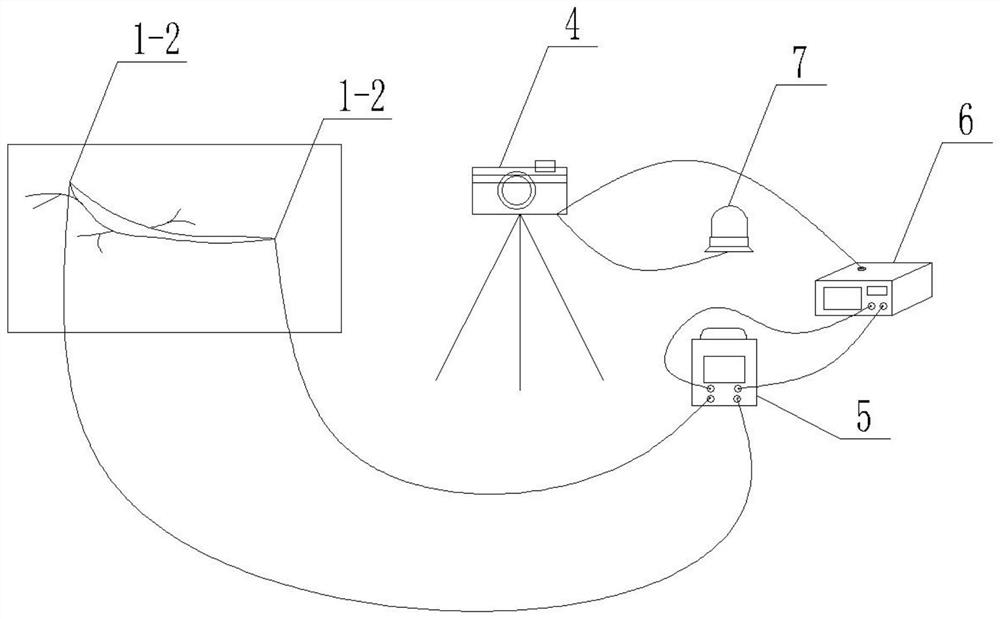

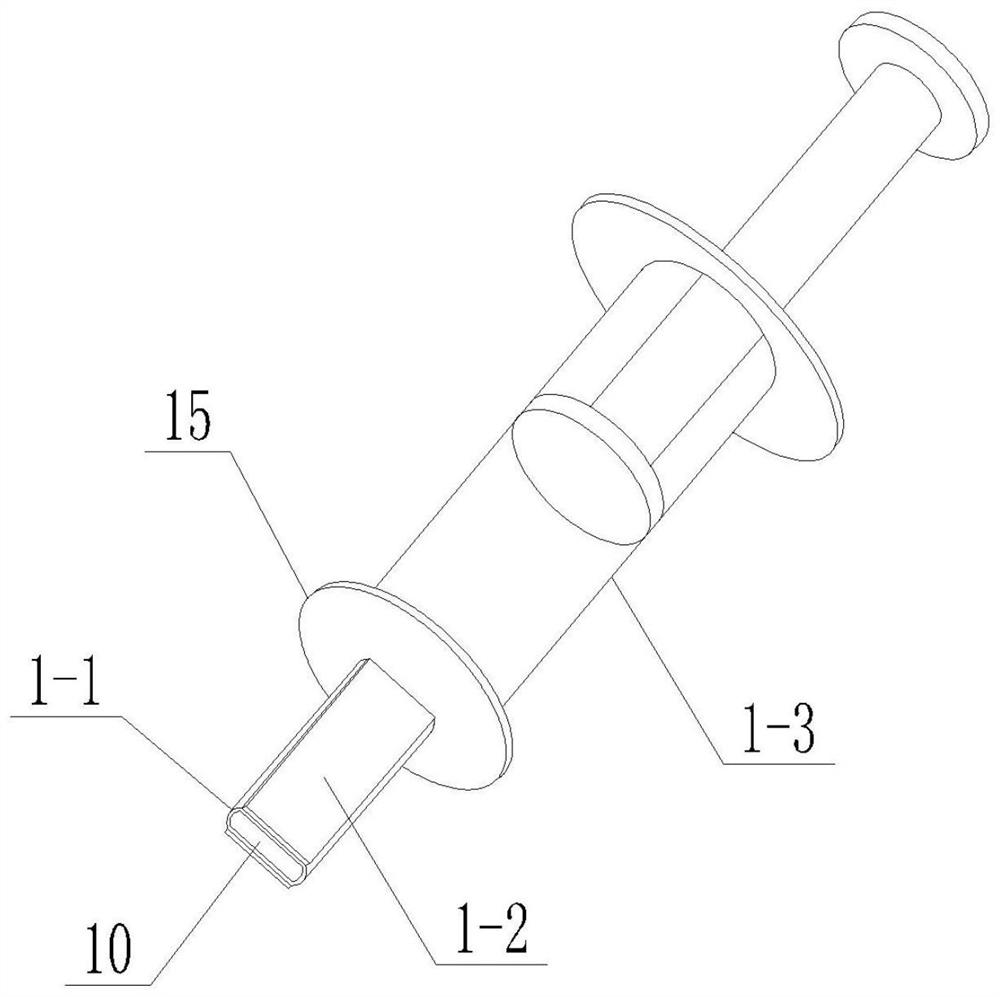

[0042] Embodiment 1: Combining Figure 1 to Figure 11 This embodiment is described. This embodiment includes an infrared thermal imager 4, a voltage regulator 5, a temperature control switch 6, an alarm 7 and two electrode syringes 1, each electrode syringe 1 includes a flat needle 1-1, an electrode The tablet 1-2 and the injection body 1-3, the flat needle 1-1 is detachably connected to the discharge end of the injection body 1-3, and the flat needle 1-1 is detachably connected to the injection body 1-3. At the discharge end, one end of the flat needle 1-1 is a feed port that communicates with the discharge end of the injection body 1-3, the other end of the flat needle 1-1 is processed with a discharge port 10, and the flat needle 1-1 An electrode sheet 1-2 is arranged on the outer side wall of the injector, the injection body 1-3 is filled with conductive concrete, and the two electrode sheets 1-2 of the two electrode syringes 1 are electrically connected to the voltage reg...

specific Embodiment approach 2

[0049] Specific implementation mode 2: Combining Figure 1 to Figure 5 This embodiment is described. The curing method in this embodiment is to heat conductive fibers in freshly mixed cement mortar to form conductive concrete, fill the conductive concrete into the electrode syringe 1, and insert the flat needle 1-1 into the existing concrete project. In the cracking gap 16, the piston end of the injection body 1-3 is controlled so that the conductive concrete fills the cracking gap 16 through the discharge port 10 of the flat needle 1-1. After filling, the injection body 1-3 is disassembled from the flat needle 1-1. Then, the electrode sheet 1-2 on the flat needle 1-1 is electrically connected to the voltage regulator 5, and according to the different resistances generated by the conductive concrete in the crack 16, the voltage regulator 5 is used to apply the corresponding voltage to the conductive concrete, Use the infrared thermal imager 4 to monitor the temperature at the ...

specific Embodiment approach 3

[0051] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. The detailed operation steps of the maintenance method described in this embodiment are:

[0052] Step 1: Preparation and use of cement mortar:

[0053] The preparation process is to add conductive fibers to the traditional cement mortar to form conductive concrete, and the conductive concrete is a fiber-reinforced cement-based composite material. The concrete is squeezed into the cracked gap 16 in the concrete project;

[0054] Step 2: After filling the crack 16, the injection body 1-3 is separated from the flat needle 1-1, and the flat needle 1-1 continues to stay in the crack 16. 1 Turn on the power, measure the resistance of the conductive concrete, set the infrared thermal imager 4 to the temperature cloud map display mode, and observe the temperature cloud map distribution. Adjust the flat needle 1-1; when the temperature difference between the highest temperature and the lowest temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com