Hot rolled dual phase steel plate with 650MPa of tensile strength and manufacturing method thereof

A tensile strength, steel plate technology, applied in the low-carbon continuous cooling low-temperature coiled hot-rolled dual-phase steel plate and its manufacturing, steel and its preparation fields, can solve the problem of difficulty in guaranteeing, prominent longitudinal unevenness of products, air-cooling start, The end temperature is difficult to accurately control and other problems, to achieve the effect of good performance, low alloy cost and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The chemical composition and weight percentage of the hot-rolled dual-phase steel plate are: C 0.08%, Si 0.69%, Mn 1.43%, P 0.009%, S 0.0041%, and the rest are Fe and other inevitable impurities.

[0036] The steel plate is simulated rolling experiment on Gleeble3800 thermal simulator, the process is:

[0037] Prepare steelmaking raw materials according to the components of the dual-phase steel plate, obtain molten steel by smelting in a converter or an electric furnace, and continuously cast it into an experimental steel block of 10×15×20 mm;

[0038] Austenitize the experimental steel block at 1200°C for 10 minutes;

[0039] After heat preservation, hot rolling is carried out, the rough rolling start temperature is 1050°C, the deformation is 0.45, and then the finishing rolling is carried out at 900°C, 875°C, 850°C and 825°C respectively, and the finishing rolling deformation is 0.28, 0.2, 0.18 and 0.15, the deformation rate is 1 / s, and the final rolling temperature ...

Embodiment 2

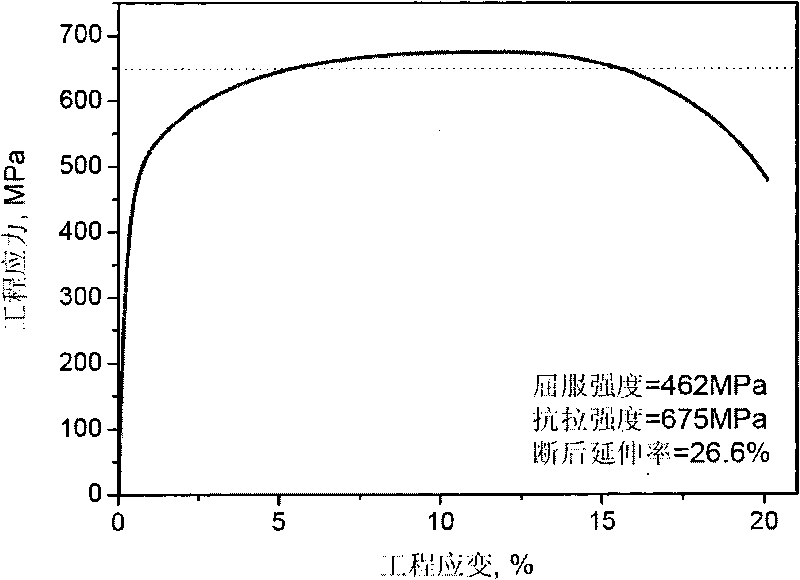

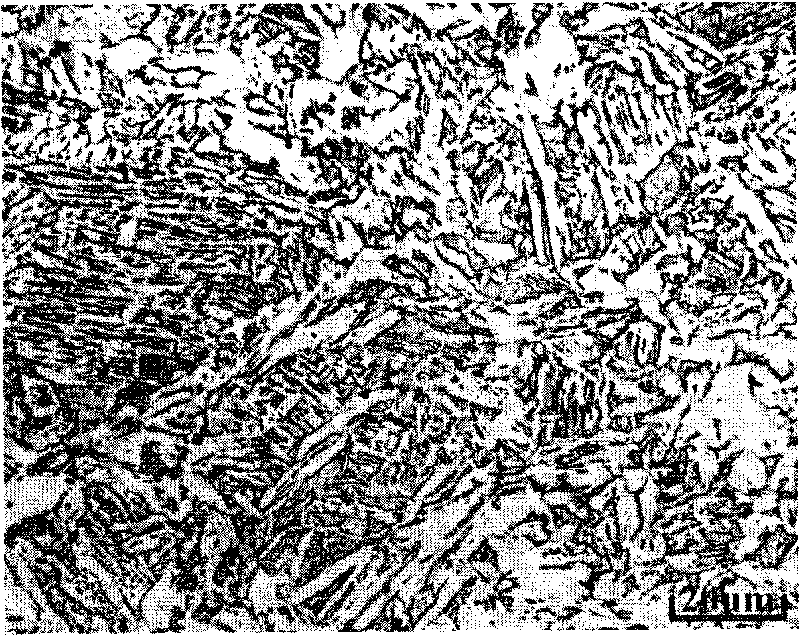

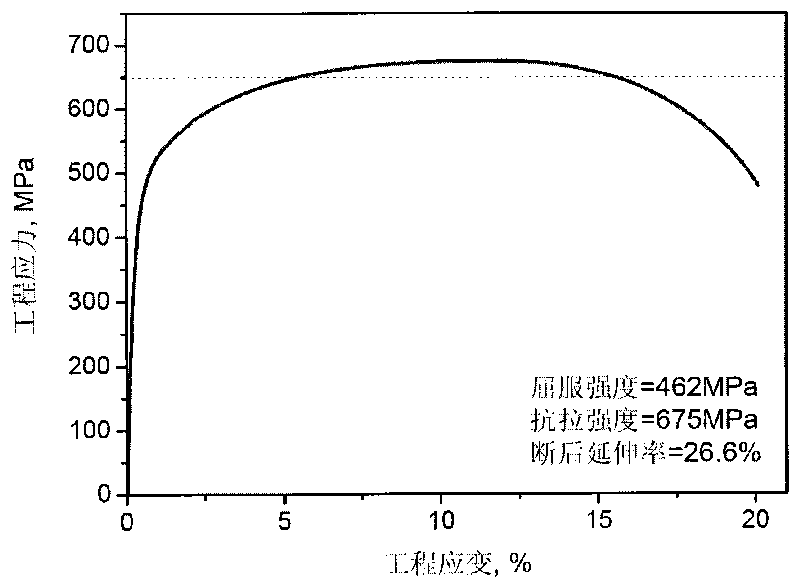

[0043] The hot-rolled dual-phase steel plate contains the same chemical composition and weight percentage as in Example 1, and its thickness specification is 10mm. The mechanical properties and structure are shown in Table 1 and Figure 1~2 . The preparation process of the hot-rolled dual-phase steel plate is as follows:

[0044] The steelmaking raw materials are configured according to the components of the dual-phase steel plate, and molten steel is obtained by smelting in a converter or an electric furnace, and continuously cast into a slab;

[0045] The slab is heated and kept at 1200°C for 2 hours;

[0046] Rolling is carried out after heat preservation, the rough rolling start temperature is 1078°C, the rough rolling reductions are 0.15, 0.20 and 0.20, the finish rolling start temperature is 963°C, and the finish rolling reductions are 0.28, 0.28, 0.26, 0.18 respectively, 0.18 and 0.13, the finishing temperature is 874°C;

[0047] After rolling, it is cooled to 200°C by...

Embodiment 3

[0049] The chemical components and weight percentages of the hot-rolled dual-phase steel sheet are the same as in Example 1, and its preparation process is similar to that of Example 2, but the starting temperature of the finish rolling is 971°C, and the finishing rolling temperature is 880°C. Continuous laminar flow cooling to 150°C and coiling, the cooling rate is 47.6°C / s. The mechanical properties of the hot-rolled dual-phase steel plate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com