Chromium bronze alloy material and preparation method thereof

A technology of bronze alloy and copper rod, which is applied in the field of chromium bronze alloy materials and its preparation, can solve the problems of poor elastic recovery ability, influence on power development, large grain size, etc., and achieve good elastic recovery ability, long service life, crystal Effects of Small Granularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

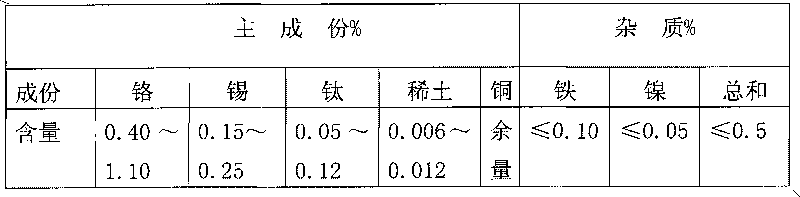

Embodiment 1

[0060] Choose No. 1 electrolytic copper 1000 kg, chromium 10 kg, tin 2 kg, titanium 1 kg, and rare earth 0.6 kg into a 1 ton intermediate frequency electric furnace for smelting. The electric furnace power is 500 kilowatts and the smelting temperature is 1340 ℃. The electrolytic copper is first melted to form liquid metal. , Then add chromium, tin, titanium and rare earth to homogenize and stir, check the chemical composition, and adopt semi-automatic continuous vibration casting. The casting temperature is 1280℃, the casting speed is 4.6m / h, and the casting water pressure is 0.5kg at the beginning. / cm 2 , 1.0kg / cm in normal 2 , Forging into a copper ingot with a specification of Ф145×L (mm), and then covering the copper ingot with dry soot as a covering agent to prevent oxidation, and then sawing with a 350mm band saw, and sawing into a semi-finished product with a specification of Ф175×L mm For copper ingots, put the semi-finished copper ingots into a 500-kilowatt intermediat...

Embodiment 2

[0062] Choose 900 kilograms of No. 1 electrolytic copper, 9 kilograms of chromium, 1.8 kilograms of tin, 0.9 kilograms of titanium, and 0.05 kilograms of rare earths into a 1 ton intermediate frequency electric furnace for smelting. The electric furnace power is 500 kilowatts and the melting temperature is 1340 ℃. , Then add chromium, tin, titanium and rare earth to homogenize and stir, check the chemical composition, and adopt semi-automatic continuous vibration casting. The casting temperature is 1280℃, the casting speed is 4.6m / h, and the casting water pressure is 0.5kg at the beginning. / cm 2 , 1.0kg / cm in normal 2 , Forging into a copper ingot with a specification of Ф175×L (mm), and then covering the copper ingot with dry soot as a covering agent to prevent oxidation, and then sawing with a 350mm band saw, and sawing into a semi-finished product with a specification of Ф175×L mm For copper ingots, put the semi-finished copper ingots into a 500-kilowatt intermediate frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com