Novel milling liquid for four-roll mill and preparation method thereof

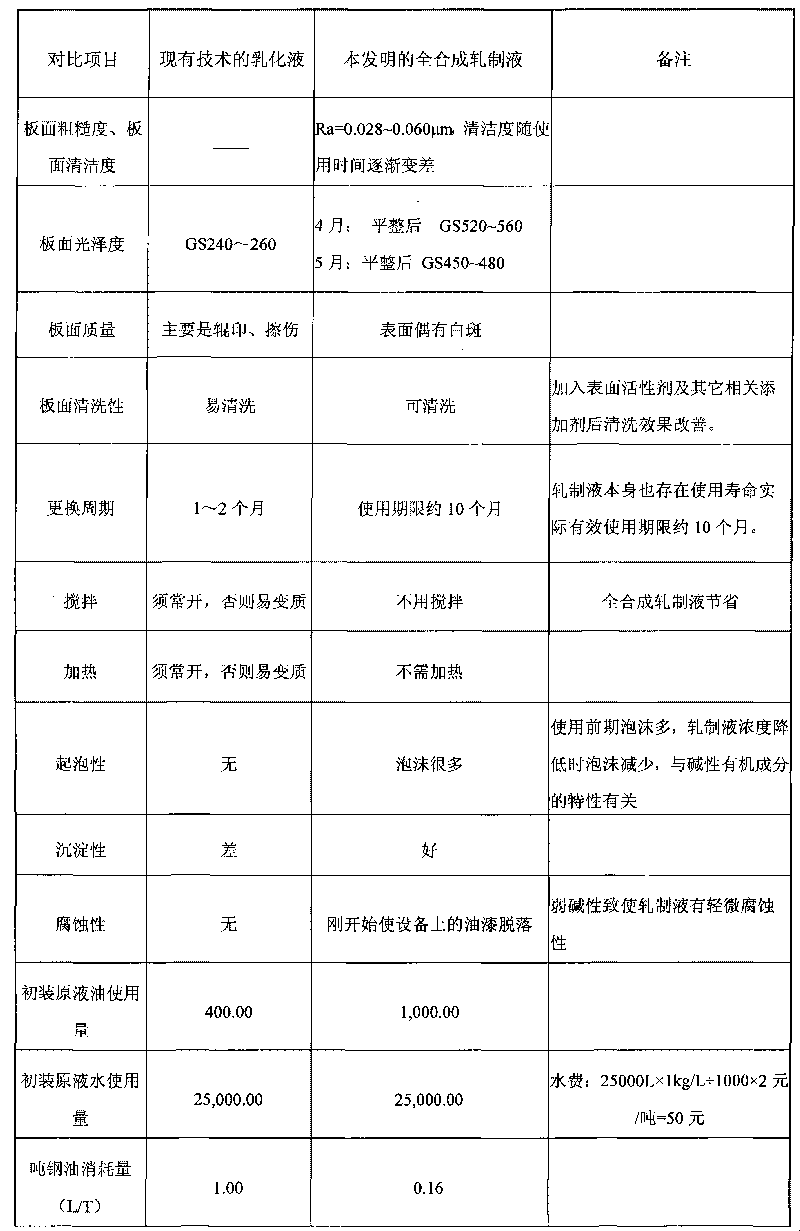

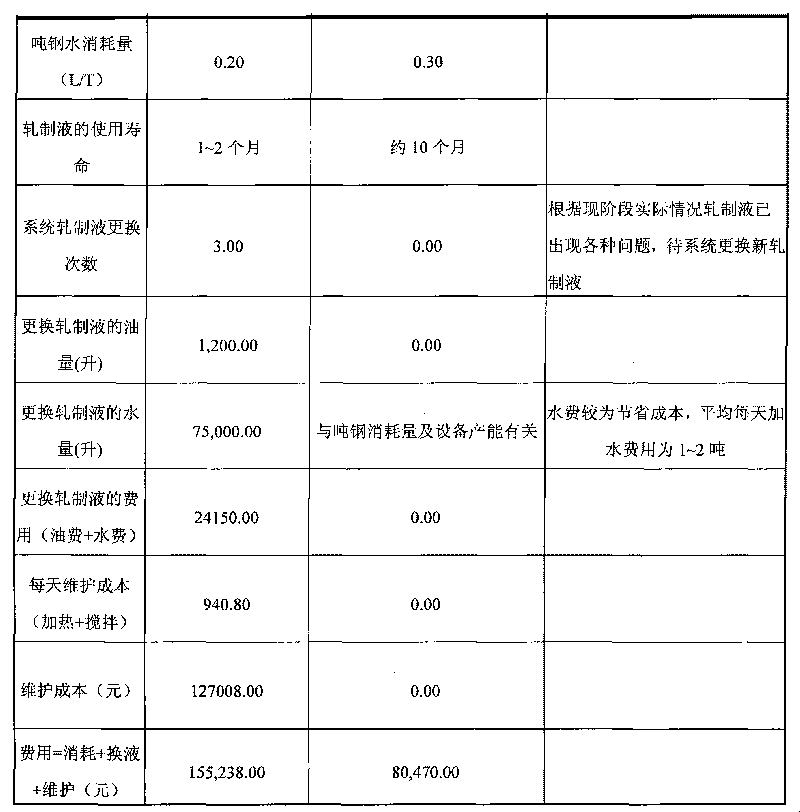

A four-high rolling mill and rolling fluid technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of short fluid replacement cycle, impact on production, and high comprehensive cost of emulsion, and achieve the effect of saving electricity expenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] N,N-Diethylethanolamine 35%

[0059] Pentaerythritol 20%

[0060] Potassium Hydroxide 10%

[0061] Sulfurized Fatty Acid Soap 3%

[0062] A mixture of triethanolamine and borate in a 1:1 weight ratio 0.4%

[0063] Formaldehyde 1.0%

[0064] Triethanolamine Oleate 5%

[0065] Simethicone 0.4%

[0066] Put 35% of N,N-diethylethanolamine, 3% of sulfurized fatty acid soap, 20% of pentaerythritol, and 10% of potassium hydroxide in a reaction vessel, heat and stir at 70°C to dissolve, until the solution is evenly mixed , then add 0.4% of triethanolamine and borate mixture in a 1:1 weight ratio, 1.0% formaldehyde, 5% oleic acid triethanolamine, heat and stir to dissolve at 70°C, and wait until the solution is mixed After uniformity, add 0.4% simethicone oil to obtain the finished rolling solution.

Embodiment 2

[0068] N,N-Dimethylethanolamine 30%

[0069] Lauryl Alcohol 25%

[0071] Sulphurized Fatty Acid Soap 5%

[0072] A mixture of triethanolamine and borate in a 1:1 weight ratio 0.4%

[0073] Formaldehyde 1.8%

[0074] Triethanolamine Oleate 10%

[0075] Simethicone 0.3%

[0076]Put 30% of N,N-dimethylethanolamine, 5% of sulfurized fatty acid soap, 25% of lauryl alcohol, and 5% of potassium hydroxide in a reaction vessel, heat and stir at 75°C to dissolve, and wait until the solution is evenly mixed Finally, add 0.4% of triethanolamine and borate mixture in a 1:1 weight ratio, 1.8% formaldehyde, and 10% oleic acid triethanolamine, and heat and stir to dissolve at 70°C. After mixing evenly, add 0.3% simethicone oil to obtain the finished rolling liquid.

Embodiment 3

[0078] N-Methyl Glycolamine 35%

[0079] Pentaerythritol 20%

[0081] Sulfurized Fatty Acid Soap 8%

[0082] A mixture of triethanolamine and borate in a 1:1 weight ratio 0.3%

[0083] Formaldehyde 1.5%

[0084] Triethanolamine Oleate 9%

[0085] Simethicone 0.3%

[0086] Put 35% of N-methylglycolamine, 8% of sulfurized fatty acid soap, 20% of pentaerythritol, and 8% of sodium hydroxide in a reaction vessel and heat and stir at 75°C to dissolve. After the solution is evenly mixed, Then add 0.3% triethanolamine and borate mixture in a 1:1 weight ratio, 1.5% formaldehyde, 9% oleic acid triethanolamine, heat and stir to dissolve at 75°C, and wait for the solution to mix evenly Finally, add 0.3% simethicone oil to obtain the finished rolling solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com