Method for preparing eutectic xylitol

A technology of xylitol and co-crystal, applied in the field of preparation of co-crystal xylitol, can solve the problems of xylitol being easy to absorb moisture and cannot be stored, frequent mechanical surface cleaning, unsuitable for gum sugar, etc. , easy operation, high product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

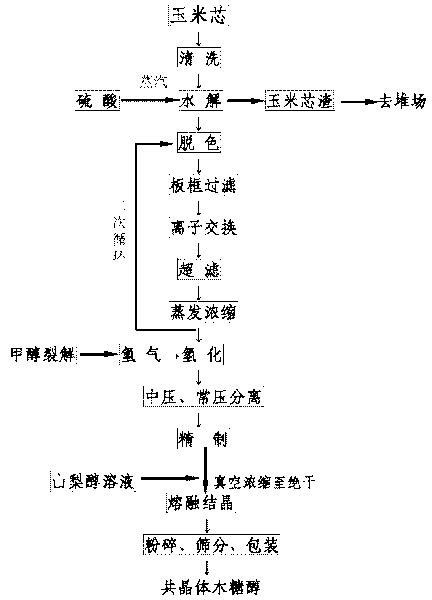

Image

Examples

Embodiment 1

[0050] A preparation method of co-crystal xylitol, comprising a xylitol liquid preparation part and a co-crystal xylitol preparation part, the specific steps are as follows:

[0051] 1. Preparation of xylitol liquid:

[0052] 1) Hydrolysis: Send the cleaned corncobs into a hydrolysis tank, add dilute sulfuric acid and pass steam for hydrolysis, control the hydrolysis temperature to 120°C, the concentration of dilute sulfuric acid to 1.5%, and the hydrolysis time for 4 hours to obtain xylose hydrolyzate;

[0053] 2) primary refining: use activated carbon to remove the pigment in the xylose hydrolyzate, then enter the plate and frame filter and ion exchange column to absorb and remove impurities in turn to obtain a refined primary xylose purification solution with a mass percentage concentration of 5% and a conductivity of 5%. 200us / cm, light transmittance 75%;

[0054] 3) One-time evaporation and concentration: use three-effect evaporation and concentration equipment to carry ...

Embodiment 2

[0064] A preparation method of co-crystal xylitol, comprising a xylitol liquid preparation part and a co-crystal xylitol preparation part, the specific steps are as follows:

[0065] 1. Preparation of xylitol liquid:

[0066] 1) Hydrolysis: Send the cleaned corncobs into a hydrolysis tank, add dilute sulfuric acid and pass steam for hydrolysis, control the hydrolysis temperature to 110°C, the concentration of dilute sulfuric acid to 1%, and the hydrolysis time for 2 hours to obtain xylose hydrolyzate;

[0067] 2) primary refining: use activated carbon to remove the pigment in the xylose hydrolyzate, then enter the plate and frame filter and ion exchange column to absorb and remove impurities in turn, to obtain a refined primary xylose purification solution with a concentration of 4% by mass and a conductivity of 4%. 100us / cm, light transmittance 70%;

[0068] 3) One-time evaporation and concentration: use three-effect evaporation and concentration equipment to carry out one-t...

Embodiment 3

[0078] A preparation method of co-crystal xylitol, comprising a xylitol liquid preparation part and a co-crystal xylitol preparation part, the specific steps are as follows:

[0079] 1. Preparation of xylitol liquid:

[0080] 1) Hydrolysis: Send the cleaned corncobs into a hydrolysis tank, add dilute sulfuric acid and pass steam for hydrolysis, control the hydrolysis temperature to 130°C, the concentration of dilute sulfuric acid to 2%, and the hydrolysis time for 6 hours to obtain a xylose hydrolyzate;

[0081] 2) primary refining: use activated carbon to remove the pigment in the xylose hydrolyzate, then enter the plate and frame filter and ion exchange column to absorb and remove impurities in turn to obtain a refined primary xylose purification solution with a mass percentage concentration of 6% and an electrical conductivity of 6%. 300us / cm, light transmittance 80%;

[0082] 3) One-time evaporation and concentration: using three-effect evaporation and concentration equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com