Production process for achieving hundred-percent comprehensive utilization and zero emission by recycling and extracting seawater

A production process and repeated cycle technology, applied in chemical instruments and methods, seawater treatment, separation methods, etc., can solve problems such as high production cost of seawater desalination, death of marine organisms, repeated cycle extraction of seawater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

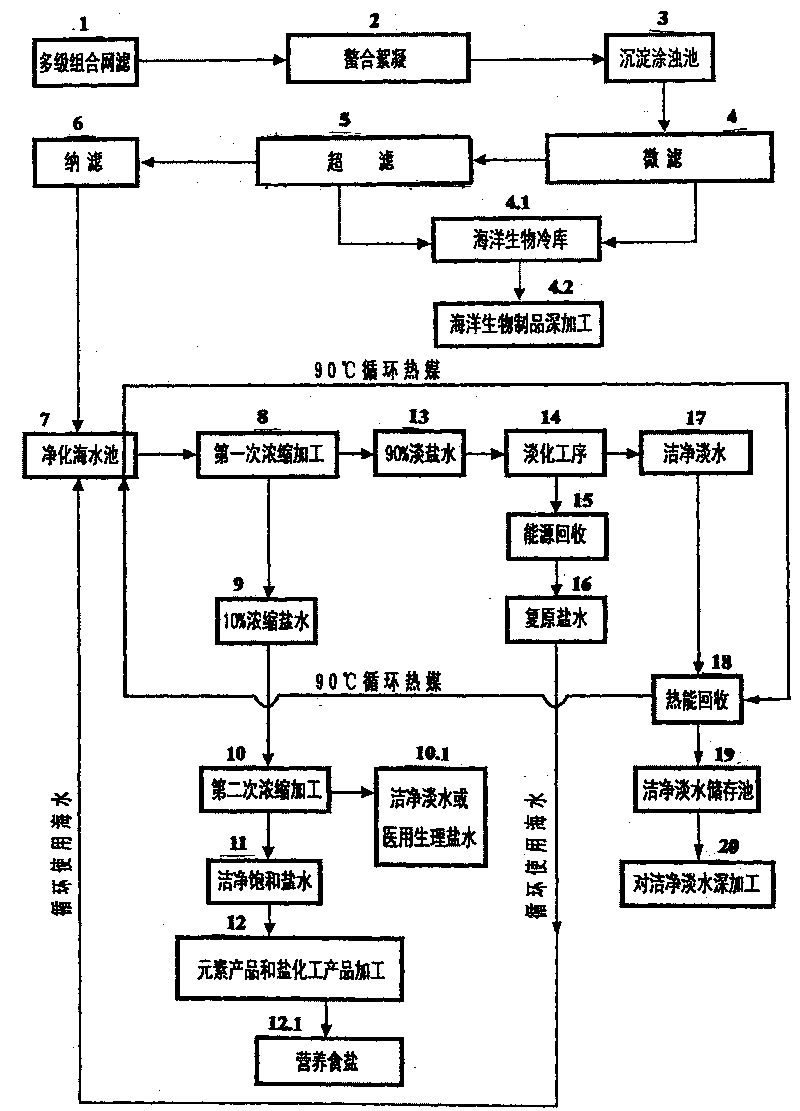

[0051] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, features, and effects of the combined production process of cyclic extraction to realize the comprehensive utilization of seawater according to the present invention will be described in detail below.

[0052] Please refer to figure 1 As shown, the present invention achieves 100% comprehensive utilization and zero discharge production process for seawater repeated circulation extraction, mainly including multi-stage combined screen filter 1, chelation flocculation 2, sedimentation and turbidity removal tank 3, microfiltration 4, and marine biological cold storage 4.1, deep processing of marine biological products 4.2, ultrafiltration 5, nanofiltration 6, seawater purification pool 7, first concentration processing 8, 10% concentrated brine 9, second concentration processing 10, clean fresh water or medical saline 10.1, clean Saturated brine 11, processing of eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com