Direct pyrolysis device

A thermal analysis and equipment technology, applied in the field of soil remediation, can solve the problems of soil loss of performance and function, high cost of incineration technology treatment, damage to soil physical and chemical properties, etc., to achieve reasonable design structure, high-efficiency processing capacity, and high energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

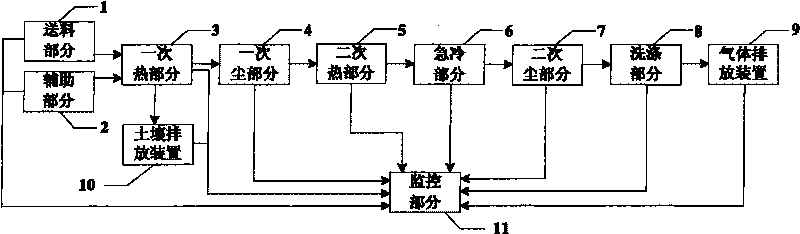

[0029] figure 1 As a structural block diagram of the present invention, the present invention provides a direct thermal desorption device, including a feeding part 1, an auxiliary part 2, a heating part, a dust removal part, a quenching part 6, a washing part 8 and a discharge part, wherein the heating part includes a primary heating Part 3 and secondary heating part 5, feeding part 1 and auxiliary part 2 are all connected with primary heating part 3; dust removal part includes primary dust removal part 4 and secondary dust removal part 7, and discharge part includes gas discharge device 9 and soil discharge device 10. The primary heating part 3 is sequentially connected with the primary dust removal part 4, the secondary heating part 5, the quenching part 6, the secondary dust removal part 7, the washing part 8 and the gas discharge device 9. In addition, the primary heating part 3 is also connected with the soil discharge device 10 connected. The feeding part, auxiliary pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com