Shape optimizing method for cylinder sleeve of slow-speed diesel

A technology for cylinder liners and diesel engines, applied to cylinders, cylinder heads, mechanical equipment, etc., can solve the problems that the design concept is difficult to fully realize, and achieve the effects of reducing weight, saving casting costs, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

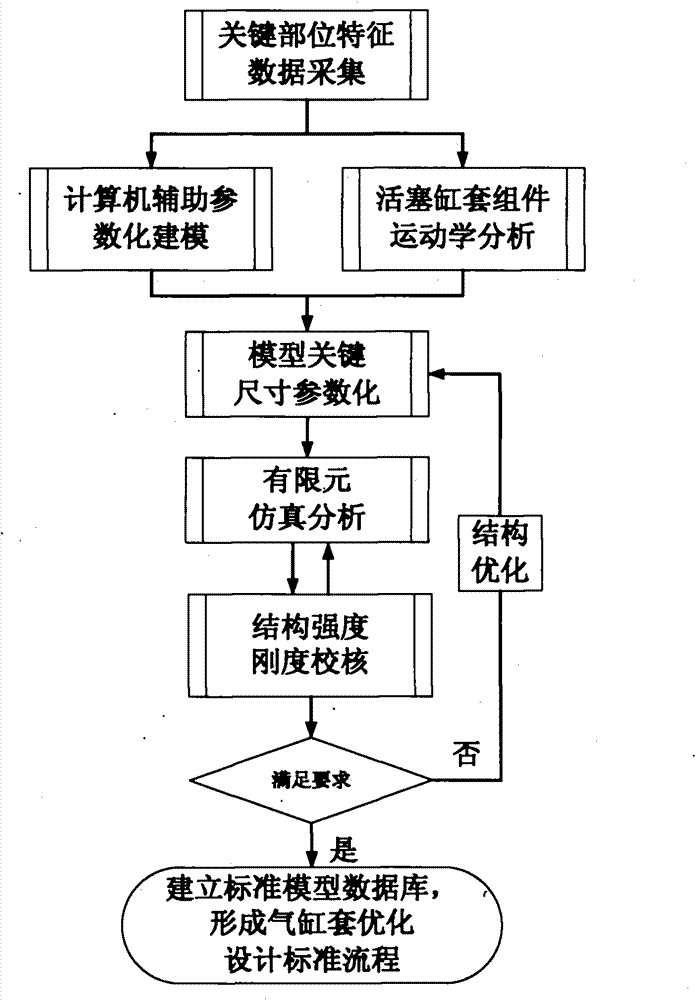

Method used

Image

Examples

Embodiment 1

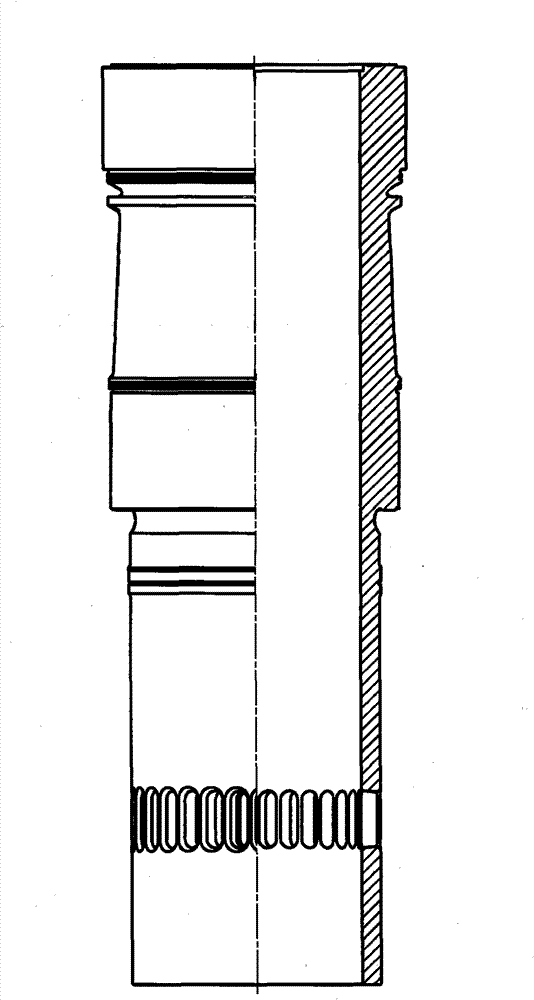

[0066] According to the above optimization design process, the cylinder liner of a certain type of high-power diesel engine is optimally designed. In this embodiment, the initial wall thickness of the cylinder liner is 72 mm, and the cylinder liner at the lower end mainly plays a guiding role and is also impacted by the piston. The strength requirement of this part is not high, so this part is optimized .

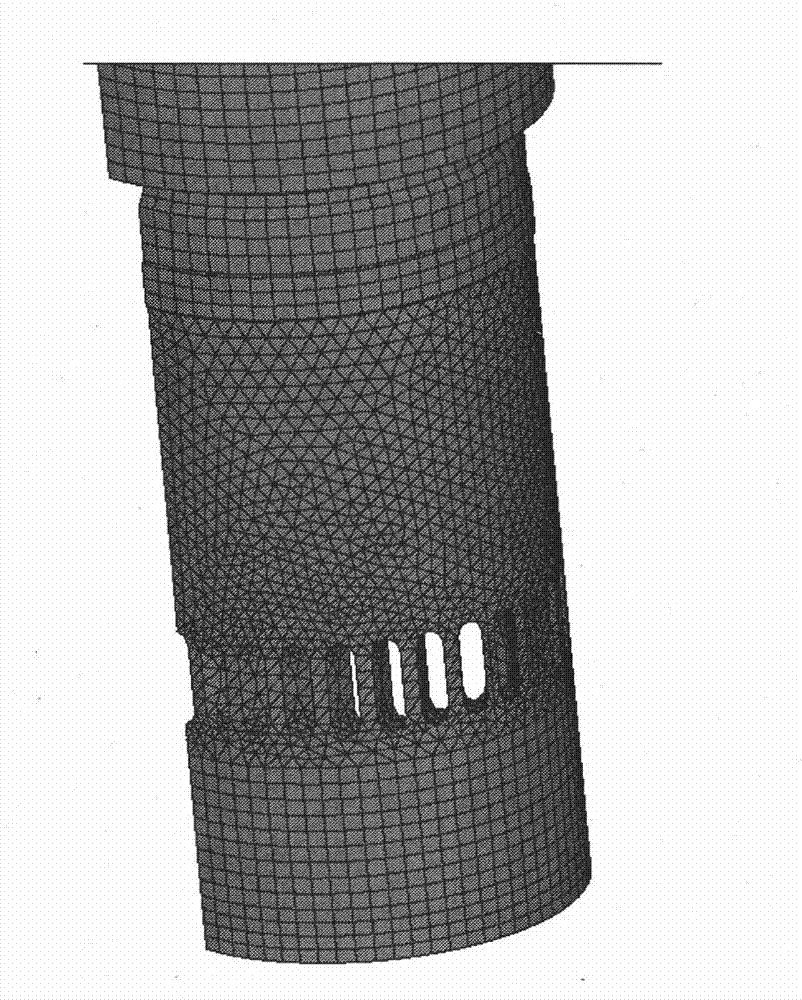

[0067] Firstly, the finite element parametric model of the cylinder liner is established, and the kinematic calculation and analysis are carried out to obtain the impact force on the cylinder liner, and then the simulation analysis of the impact response is carried out. Under the impact of the piston, the maximum VON Mises stress of the original structure is calculated to be 149MPa, and the maximum deformation is 2.2mm; after reducing the wall thickness of the cylinder liner by 22mm, the impact response analysis is carried out, and the maximum VON Mises stress of the optimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com