Rear ring back-turning type balance drum of multi-stage pump

A balance drum and fold-back technology, applied in the field of balance drums, can solve the problems of low pump efficiency and large leakage in the sealing gap, and achieve the effects of improving efficiency, enhancing the balance effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

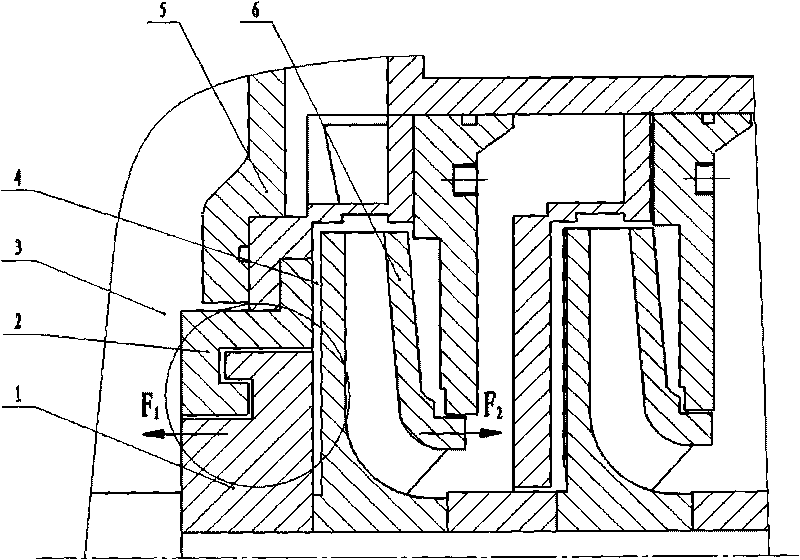

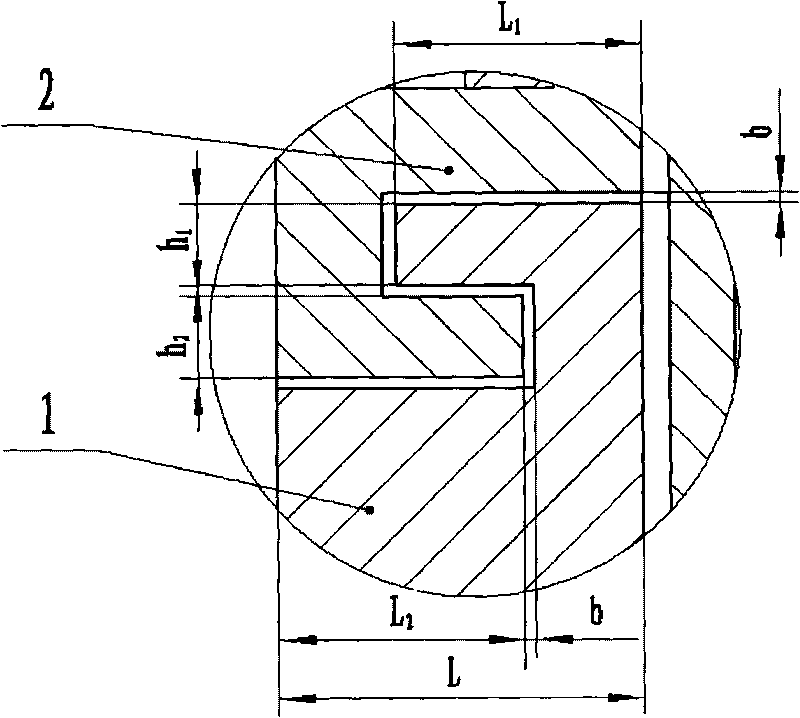

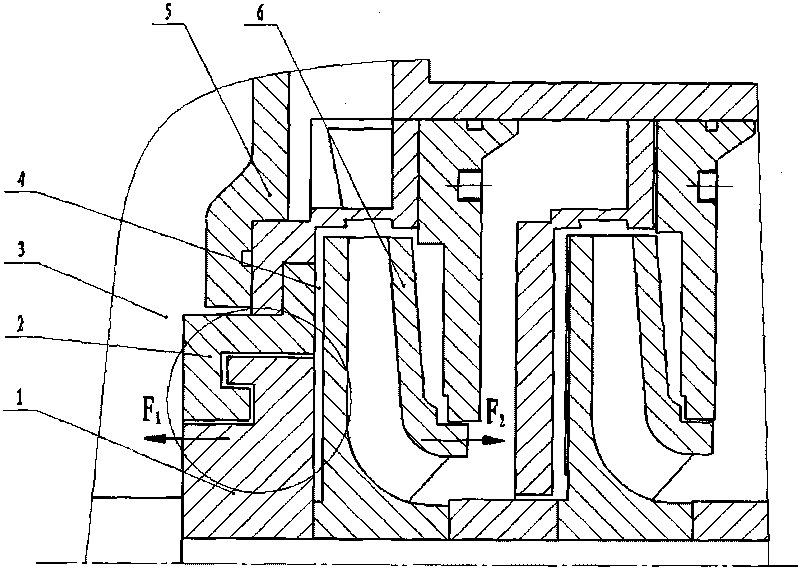

[0010] figure 1 Among them, there is a return ring surface on the outer circle of the balance drum 1, the ring surface turns back from the direction of the rear pump chamber 4 to the direction of the balance chamber 3, and the axial length of the ring surface is L 1 It is 1 / 2~3 / 4 of the axial length L of the balance drum, and the thickness h 1 3~10mm; in the inner circle of the balance sleeve 2, there is a return ring surface corresponding to the outer circle return ring surface of the balance drum 1. This ring surface is turned back from the direction of the balance chamber 3 to the direction of the rear pump chamber 4, and the axial length of the ring surface is L 2 The axial length L of the outer circle of the balance drum 1 1 equal, thickness h 2 Thickness h of the outer circle of the balance drum 1 1 equal. The two return ring surfaces cooperate with each other to form an S-shaped sealing gap, and the gap value b is both 0.2-0.3mm. Under the condition that the pump r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com