Method for preparing glutathione by fed-batch fermentation of Candida utilis

A technology of candida utilis and fed-batch fermentation, which is applied in the field of microbial fermentation, can solve the problems of insufficient supply of nutrients, excess nutrition, insufficient supply of yeast nutrients, etc., and achieve the goal of improving production efficiency, reducing fermentation time, and increasing GSH production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: adopt constant-speed fed-batch fermentation culture under the condition that the total glucose concentration is 150g / L

[0035] (1) strain

[0036] Candida utilis (Candida utilis) SZU 07-01 is preserved by Industrial Microbiology Laboratory of Soochow University.

[0037] (2) culture medium

[0038] Slope and seed medium (g / L): glucose 20, peptone 20, yeast extract 10, pH 6.0;

[0039] Batch fermentation medium (g / L): glucose 30, ammonium sulfate 8, potassium dihydrogen phosphate 3, magnesium sulfate 0.25, pH 5.5;

[0040] Feed medium (g / L): glucose 600, ammonium sulfate 80, potassium dihydrogen phosphate 30, magnesium sulfate 2.5.

[0041] (3) Seed cultivation

[0042] After the slant seeds are activated for 4 to 6 hours, insert them into a 500mL Erlenmeyer flask containing 50mL of seed medium and cultivate them for 18 to 24 hours to obtain the first-grade seeds, and then insert the first-grade seeds into the same medium according to the inoculum am...

Embodiment 2

[0058] Embodiment two: under the condition that total glucose concentration is 150g / L, adopt exponential fed-batch fermentation culture

[0059] With reference to Embodiment 1, the difference is:

[0060] (4) Fermentation tank culture

[0061] Batch fermentation: put the prepared secondary seeds into the fully automatic fermentation tank with 3L fermentation medium according to the inoculum amount of 10%, and cultivate them in batches for 24-30 hours, the fermentation temperature is 28-32°C, and the stirring speed is 300rpm , Ventilation 1vvm.

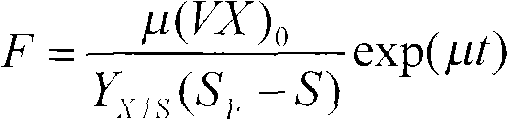

[0062] Exponential fed-batch fermentation: During 10 to 12 hours of batch fermentation, feeding medium is fed into the fermenter, and the flow acceleration rate F (mL / h) is determined by the exponential equation:

[0063] F = μ ( VX ) 0 Y ...

Embodiment 3

[0069] Embodiment three: under the condition that the total glucose concentration is 150g / L, adopt polynomial fed-batch fermentation culture

[0070] With reference to Embodiment 1, the difference is:

[0071] (4) Fermentation tank culture

[0072] Batch fermentation: put the prepared secondary seeds into the fully automatic fermenter with 3L fermentation medium according to the inoculum amount of 10%, cultivate for 24-30 hours, the fermentation temperature is 28-32°C, the stirring speed is 300rpm, and the ventilation The amount is 1vvm.

[0073] Polynomial fed-batch fermentation: During the 10th to 12th hour of batch fermentation, the feed medium is fed into the fermenter, and the flow acceleration rate F (m L / h) is determined by the polynomial equation:

[0074] F=34.566-4.994*t+1.235*t 2 -0.041*t 3

[0075] The culture conditions are the same as batch culture, and the dissolved oxygen concentration is controlled to not be lower than 35% by manually adjusting the speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com