Motorcycle vibration damping type frame

A motorcycle and frame technology, which is applied in the field of off-road motorcycle vibration-damping frames, can solve the problems that the strength and rigidity of the frame cannot be increased, the assembly process is complex, and the processing process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

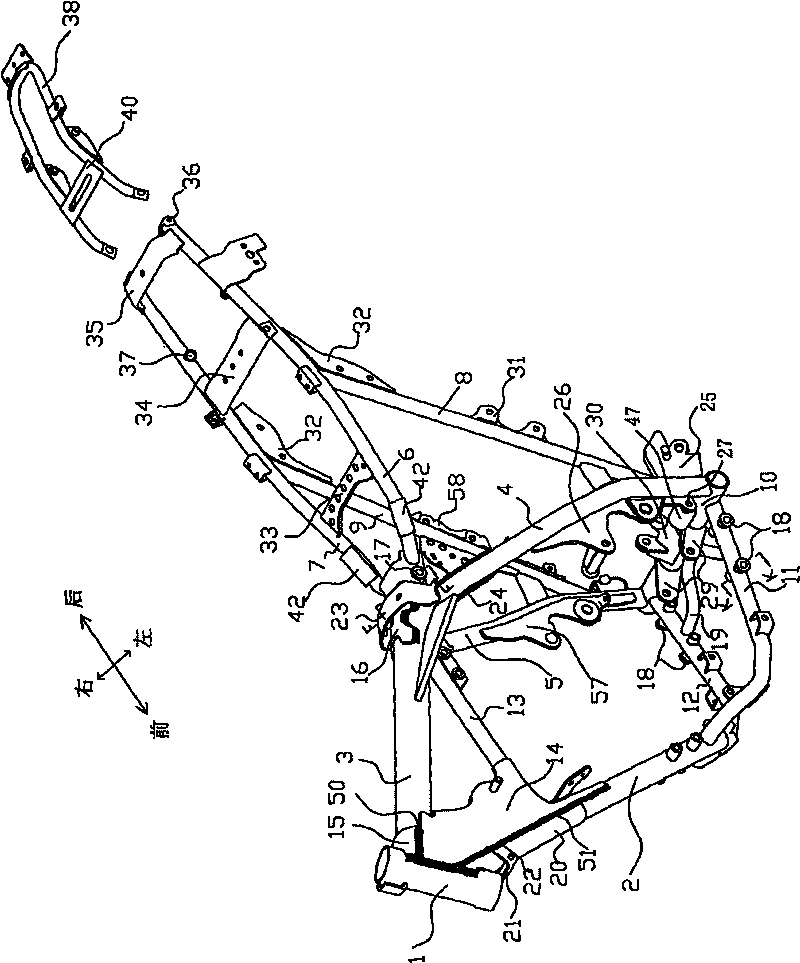

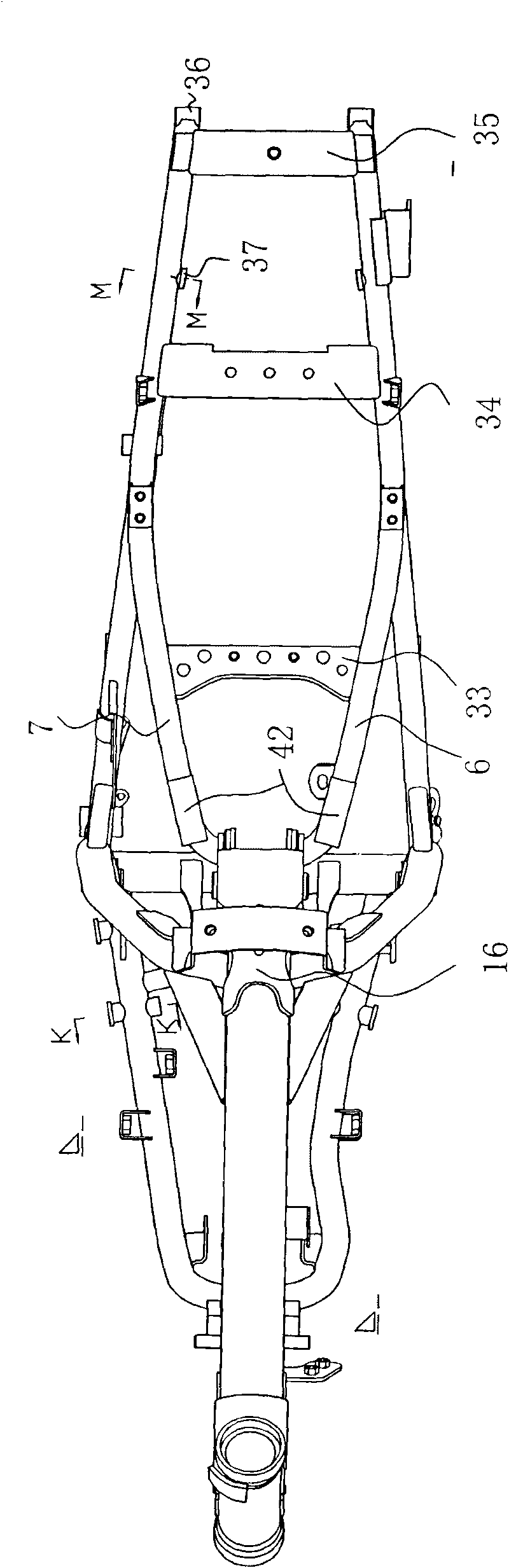

[0029] The best implementation of the technical solution will be described below according to the description of the accompanying drawings. The drawings should be in accordance with figure 1 The marked direction is the benchmark of observation.

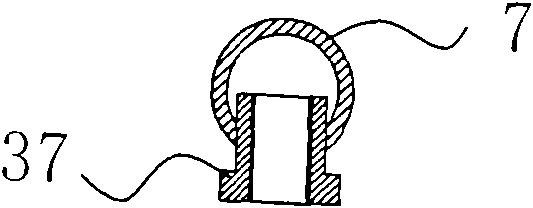

[0030] figure 1It is a three-dimensional view of a motorcycle frame adopting the new structure, including a riser tube 1, a front diagonal brace tube 2, a main beam tube 3, a left main brace tube 4, a right main brace tube 5, a left tail tube 6, and a right tail tube Pipe 7, left rear inclined pipe 8, right rear inclined pipe 9, engine lower horizontal pipe 10, bracket left lower pipe 11, bracket right lower pipe 12, main beam reinforcement pipe 13. The main beam tube 3 adopts a circular tube structure and is fixed together with the standpipe 1 at a certain angle. The front brace tube 2 is also fixed at a certain angle with the standpipe 1 and extends from the top to the bottom and rear. The front brace tube 2 passes through The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com