Method for concentrating extraction liquid in production of tobacco sheet by papermaking process

A technology of tobacco sheet and extraction liquid, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of poor quality of tobacco sheet evaluation and dull smoke, and achieve the effects of improving use value, improving smoking quality and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

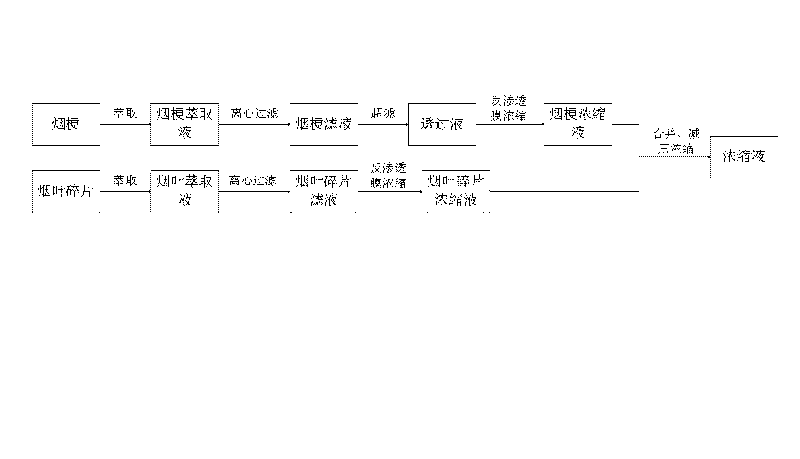

Embodiment 1

[0050] 700kg of tobacco stems and 700kg of tobacco leaf fragments were soaked in 40°C hot water and 30°C for 1.5 hours respectively, and extracted to obtain tobacco stem extract and tobacco leaf fragment extract; the tobacco stem extract was discarded, and the tobacco leaf fragment extract was subjected to centrifugal filtration and reverse osmosis The membrane is concentrated, and then concentrated under vacuum and reduced pressure. The final concentrated solution is dip-coated on the formed substrate, dried, punched, and formed.

[0051] The thin slice better maintains the original fragrance of tobacco, can feel obvious tobacco smell, and has good smoking quality. The internal quality comparison is shown in the table below. The test sample is a new process sample, and the control is a sample that does not use the membrane concentration process.

[0052] sample

[0053] sample

Embodiment 2

[0055] 700kg of tobacco stems and 700kg of tobacco leaf fragments were soaked in 70°C hot water for 1 hour and 60°C for 0.5 hour, respectively, and extracted to obtain tobacco stem extracts and tobacco leaf fragments extracts. The extract of mixed tobacco stems and tobacco leaf fragments is centrifugally filtered, concentrated by reverse osmosis membrane, and then concentrated by vacuuming and decompression. The final concentrated solution is dip-coated on the formed sheet substrate, dried, sliced, and formed.

[0056] The thin slice better maintains the original aroma of tobacco, can feel obvious tobacco smell, and has better smoking quality. The internal quality comparison is shown in the table below. The test sample is a new process sample, and the control is a sample that does not use the membrane concentration process.

[0057] sample

Embodiment 3

[0059] 700kg of tobacco stems and 700kg of tobacco leaf fragments were soaked in 70°C hot water for 1 hour and 60°C for 0.5 hour, respectively, and extracted to obtain tobacco stem extracts and tobacco leaf fragments extracts. The extract of tobacco leaf fragments is centrifugally filtered and concentrated by a reverse osmosis membrane; the extract of tobacco stems is centrifugally filtered and then filtered by an ultrafiltration membrane to obtain a permeate, which is then concentrated by a reverse osmosis membrane. Combining the concentrated solution of tobacco stems and fragments and then concentrating under vacuum and reduced pressure; the final concentrated solution is dip-coated on the shaped substrate, dried, punched, and shaped.

[0060] The thin slice better maintains the original fragrance of tobacco, can feel obvious tobacco smell, and has good smoking quality. The internal quality comparison is shown in the table below. The test sample is a new process sample, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com