Translational compound paired mould of dumpling machine

A translational, dumpling machine technology, applied in the direction of baking, dough processing, food science, etc., can solve the problems of increasing costs and consuming man-hours, and achieve the effects of saving man-hours and costs, solving industry problems, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

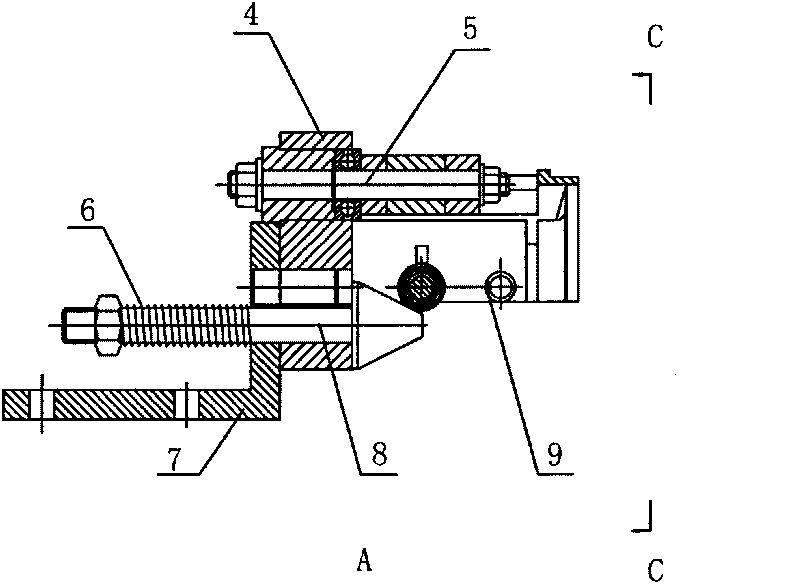

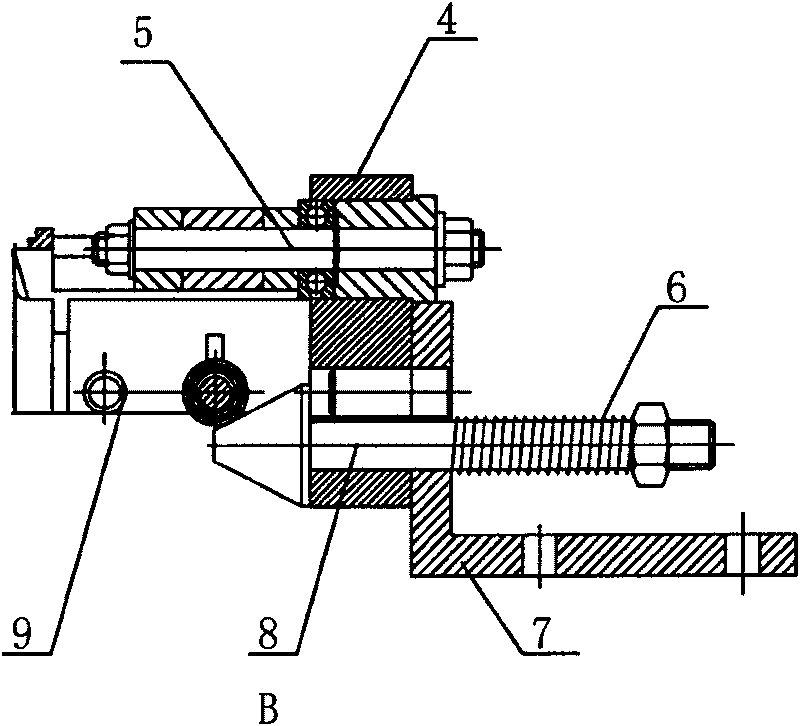

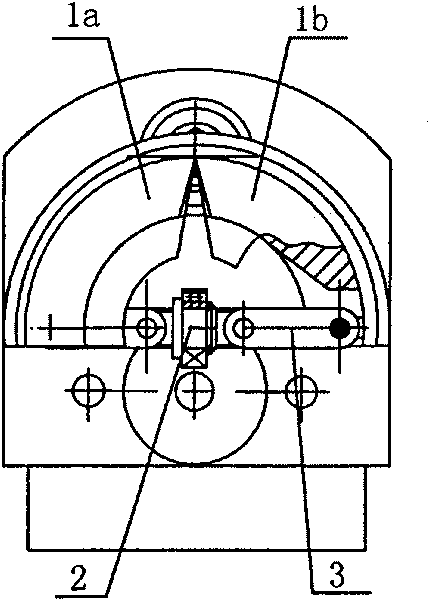

[0013] Reference attached Figure 1~3 , Dumpling machine translational composite mold is composed of a set of translational composite mold A and composite mold B. The composite mold A and composite mold B are composed of mold base 4, corner plate 7, parting mold 1a and parting mold. 1b composition. The upper part of the parting mold 1a and the parting mold 1b are connected in a hinge manner by a centering shaft 5, and the lower part of the parting mold 1a and the parting mold 1b are connected to a connecting shaft 2 equipped with a bearing 10 through a chain plate 3. The bearing 10 on the connecting shaft 2 is matched with the conical surface of the push rod 8. The push rod 8 is equipped with a main spring 6, and a return spring 9 is also installed on the parting mold 1a and the parting mold 1b, the composite pair mold A and the composite pair The mold B is installed on the guide rail pair through the corner plate 4. When the push-pull rod 8 moves forward and the composite co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com