Low-temperature high-toughness F460 grade super strength steel plate for building ship and manufacturing method thereof

An ultra-high-strength, marine steel plate technology, used in manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problems of difficult manufacturing, complex composition design, unachieved, etc., to achieve good welding performance and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The low-temperature high-toughness F460 grade ultra-high-strength steel plate for shipbuilding contains components and their weight percentages: C0.06%, Si 0.23%, Mn 1.45%, P 0.008%, S 0.0009%, Nb 0.032%, V 0.04%, Ti 0.019%, Cu 0.23%, Cr 0.151%, Ni 0.22%, Al 0.042%, and the balance of Fe and unavoidable impurity elements.

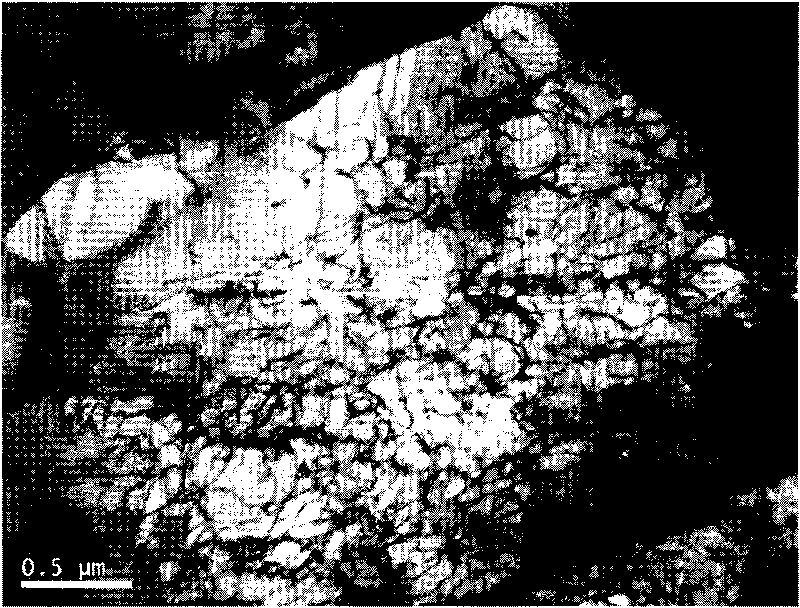

[0039] The low-temperature high-toughness F460 grade ultra-high-strength shipbuilding steel plate has a thickness of 60mm, yield strength ≥ 460MPa, tensile strength ≥ 570MPa, elongation ≥ 17%, and impact energy at -60°C ≥ 31J. And if Figure 1~3 As shown, the metallographic structure of the marine steel plate is acicular ferrite + polygonal ferrite.

[0040] The preparation process of the low-temperature high-toughness F460 grade ultra-high-strength steel plate for shipbuilding is as follows:

[0041] Prepare smelting raw materials according to the composition of the shipbuilding steel plate, melt and cast it to form a continuous casting slab with ...

Embodiment 2

[0047] The low-temperature high-toughness F460 grade ultra-high-strength steel plate for shipbuilding contains components and their weight percentages: C0.06%, Si 0.23%, Mn 1.45%, P 0.008%, S 0.0009%, Nb 0.032%, V 0.04%, Ti 0.019%, Cu 0.23%, Cr 0.151%, Ni 0.22%, Al 0.042%, and the balance of Fe and unavoidable impurity elements.

[0048] The low-temperature high-toughness F460 grade ultra-high-strength steel plate for shipbuilding has a thickness of 50mm. In the controlled rolling process, the starting temperature of rough rolling is 1030°C, the thickness to be warmed is 150mm, and the starting temperature of finish rolling is 830°C; in the controlled cooling process, the starting cooling temperature is controlled at 790°C, the final cooling temperature is 500°C, The speed is 10°C / s.

[0049] The impact properties of the low-temperature high-toughness F460 grade ultra-high-strength shipbuilding steel plate under the conditions of hot rolling, strain aging, stress relief annea...

Embodiment 3

[0051] The low-temperature high-toughness F460 grade ultra-high-strength steel plate for shipbuilding contains components and their weight percentages: C0.06%, Si 0.23%, Mn 1.45%, P 0.008%, S 0.0009%, Nb 0.032%, V 0.04%, Ti 0.019%, Cu 0.23%, Cr 0.151%, Ni 0.22%, Al 0.042%, and the balance of Fe and unavoidable impurity elements.

[0052] The low-temperature high-toughness F460 grade ultra-high-strength shipbuilding steel plate has a thickness of 18mm. Billet heating temperature is 1250°C, heat preservation 2.5h, rough rolling start temperature is 1110°C, waiting temperature is 64mm, finish rolling start temperature is 870°C, start cooling temperature is 830°C, final cooling temperature is 500°C, cooling rate is 12°C / s.

[0053] The mechanical properties of the low-temperature high-toughness F460 grade ultra-high-strength shipbuilding steel plate are shown in Table 8.

[0054] The above-mentioned embodiments are only to illustrate the technical concept and characteristics of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com