Protective sliding door used for steel slag treatment

A sliding door and steel slag technology, applied in the field of protective sliding doors for steel slag treatment, can solve the problems of door panel and workshop damage, airflow impact, door panel damage quickly, etc., to avoid damage, not easy to damage, and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings.

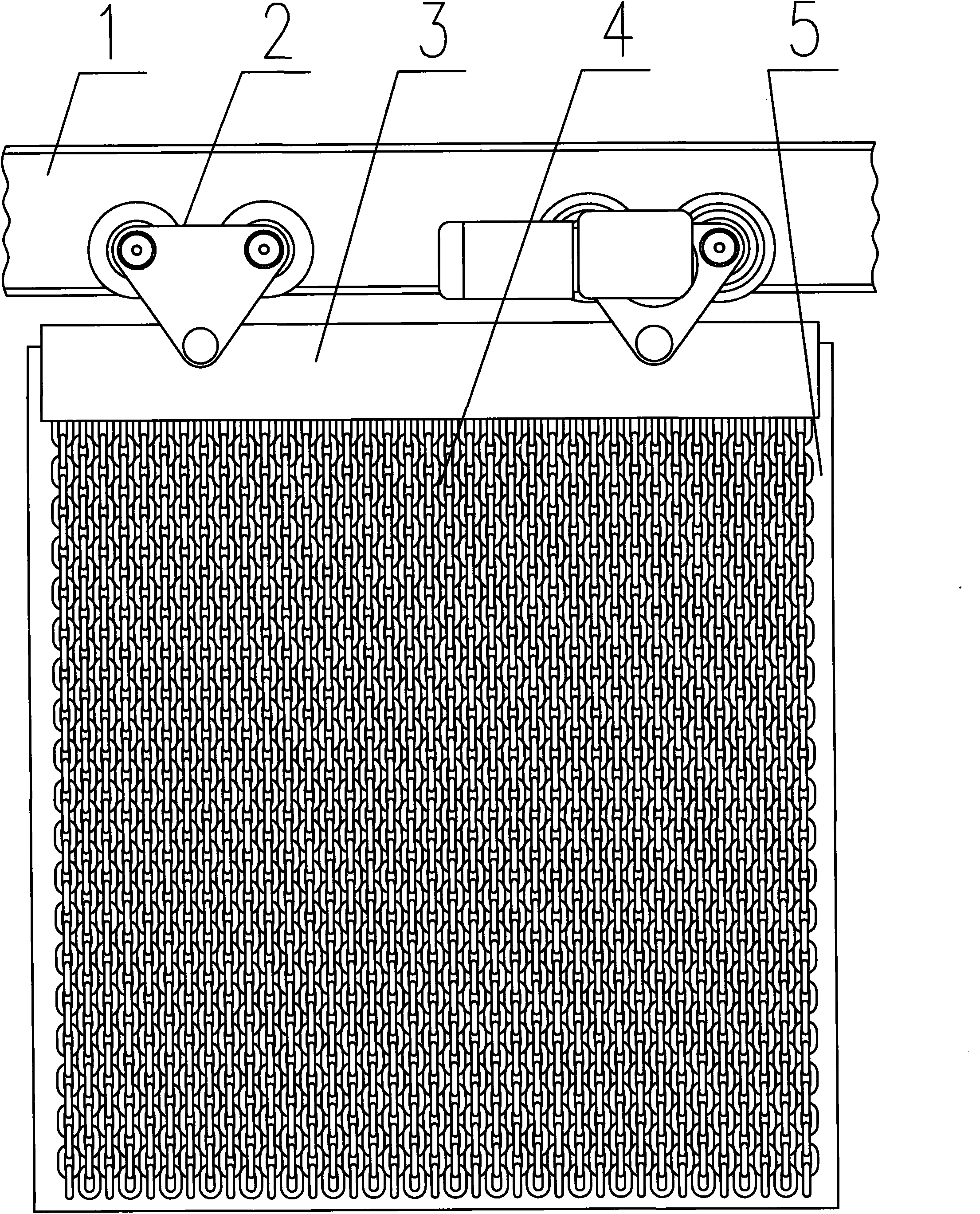

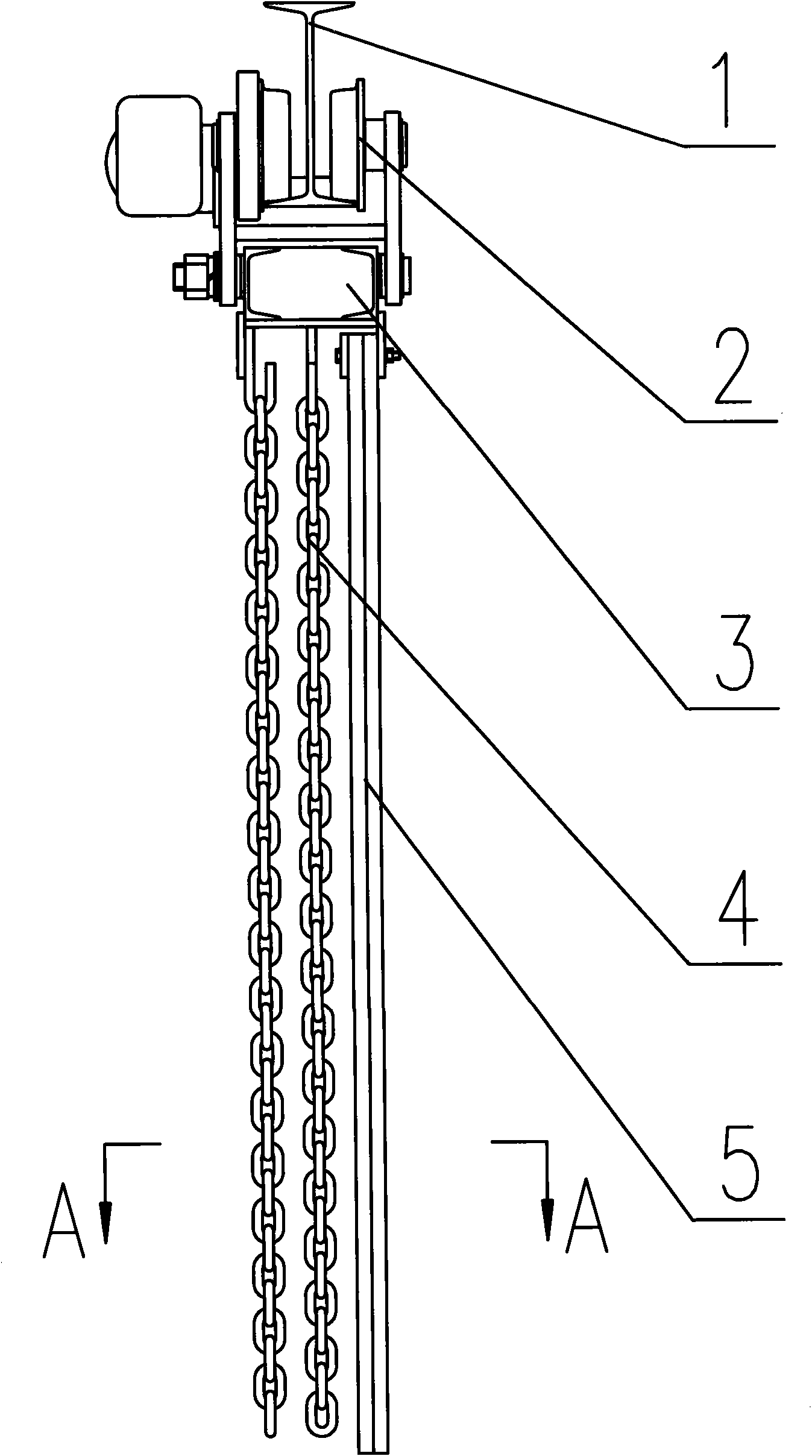

[0015] Such as figure 1 , 2 As shown, the present invention includes a track 1, and the track 1 is an I-shaped steel structure. The mobile traveling device 2 is a walking wheel group structure, and the mobile traveling device 2 includes a roller and a triangular plate, the rollers are fixed on the triangular plate, and the rollers are placed on the track 1 . The door beam 3 is a strip-shaped part, and the door beam 3 is hung with a flexible door, and the door beam 3 is fixed with the triangular plate of the mobile walking device 2 . The motor is connected with the roller through the reducer to provide power for the mobile traveling device 2; rollers are installed on both sides of the I-shaped track. Walk in a straight line to realize the opening and closing function of the protective door.

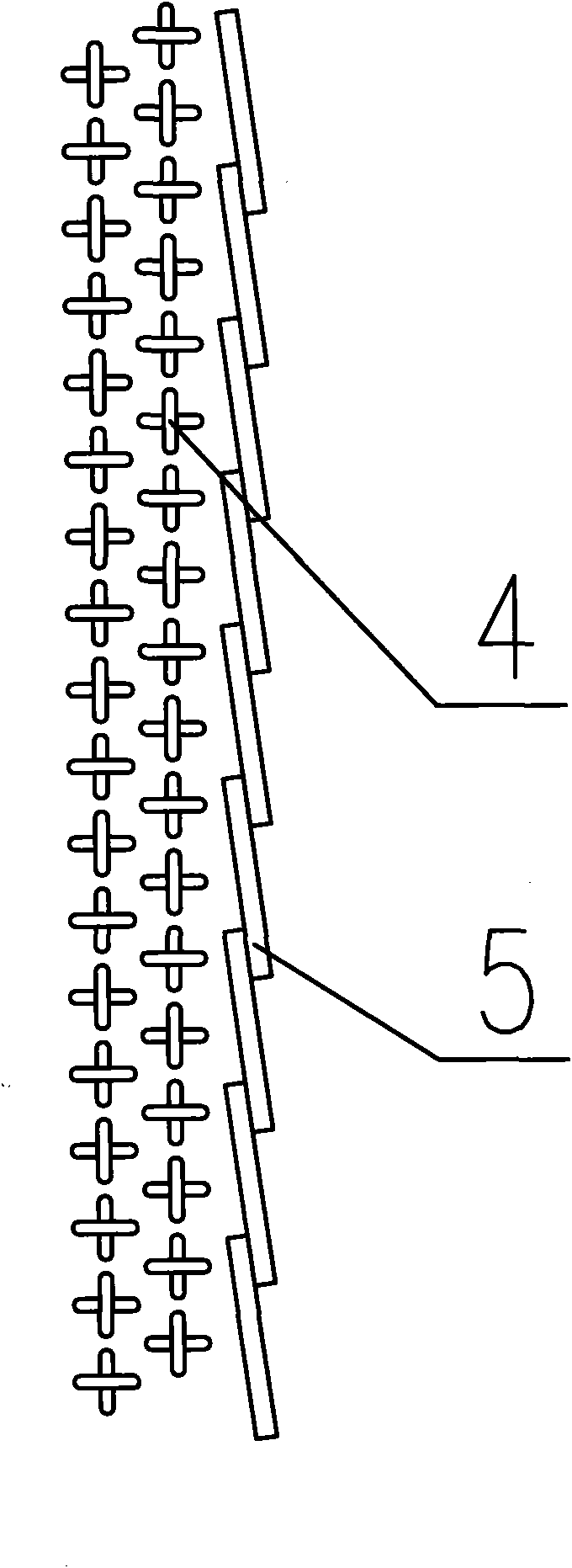

[0016] Such as figure 2 , 3 As shown, a chain door 4 is hung on the doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com