Method for preparing radix actinidia chinensis polysaccharide extract

A technology for extracting kiwifruit root and polysaccharide is applied in the field of preparation of kiwifruit root polysaccharide extract, which can solve the problems of low extraction rate, purity and pharmacodynamic activity of kiwifruit root polysaccharide, increase hidden dangers in safety, complicated operation and the like, and improve production safety. , the effect of saving the amount of ethanol and reducing the amount of ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Determination of the Active Part of the Kiwi Root Crude Polysaccharide Extract

[0030] Take 5000g of dried kiwi root decoction pieces, add 10 times the quality of water, heat and reflux extraction 3 times, 2 hours each time, combine the extracts, high-speed centrifugation (15000r / min, 20min), and pass the supernatant through a microporous membrane with a pore size of 0.45μm , the filtrate adopts ultrafiltration membranes with a molecular weight cut-off of 3 million, 1 million, 100,000, 30,000, and 5,000 in sequence, and performs ultrafiltration classification to obtain A (below 5,000), B (5,000-30,000), and C (30,000 -100,000), D (100,000-1 million), E (1 million-3 million), F (more than 3 million) and other 6 parts. Each part is concentrated and dried respectively, and its polysaccharide content is measured respectively, and its percentage in the total extract (polysaccharide) is calculated.

[0031] The extracts of kiwifruit roots from various parts were ...

Embodiment 2

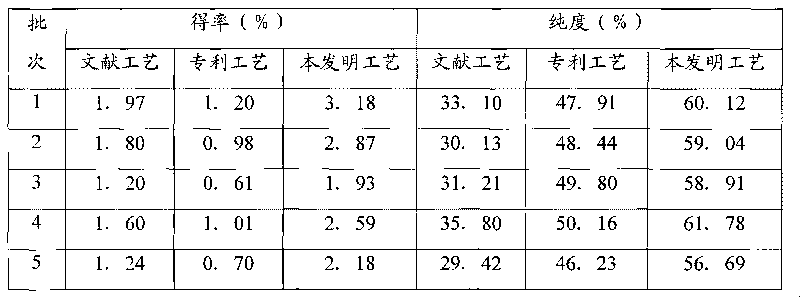

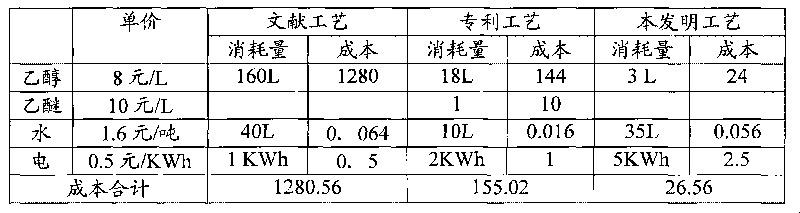

[0035]Embodiment 2: the comparison of technology of the present invention and existing technology

[0036] Get the same batch of kiwifruit roots, extract the kiwifruit root polysaccharides respectively by methods such as literature process, patented process and process of the present invention, and compare (5 batches of each method):

[0037] Literature process (i.e. method 1 in the background technology part): dry 1000g of kiwifruit root decoction pieces, add 20 times the quality of water to extract, extract twice for 0.5h each time, add ethanol to the water extract to make the alcohol content reach 80% (v / v), standing overnight, suction filtration, to obtain the product.

[0038] Patented process (i.e. the method 2 of the background technology part): 1000g of dried kiwifruit root decoction pieces, add 5 times the mass of 30% (v / v) ethanol and soak twice, each time for 24 hours, let stand, take the supernatant, combine, Add ethanol to adjust the ethanol content to 72% (v / v)...

Embodiment 3

[0047] Embodiment 3: the preparation of kiwifruit root polysaccharide

[0048] Take 500 g of dried kiwi root decoction pieces, add 6 times the mass of water, heat and reflux for 1 hour, extract 3 times, combine the extracts, centrifuge at high speed (10000r / min, 20min), and pass the supernatant through a microporous membrane with a pore size of 0.65 μm. The filtrate is ultrafiltered with a membrane with a molecular weight cut-off of 3000000Da, and the ultrafiltrate is ultrafiltered with a membrane with a molecular weight cut-off of 5000Da, concentrated to 500ml, and the concentrated solution is added with ethanol to adjust the alcohol concentration to 55% (v / v), and stand for 60 hours at high speed Centrifuge (10000r / min, 20min), wash the precipitate once with absolute ethanol, and dry to obtain the crude polysaccharide from kiwifruit root. After measurement and calculation, the yield of crude polysaccharide from kiwifruit root is 2.07%, and the purity is 55.81%.

[0049] Take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com