Cavitation-corrosion-resistant surfacing welding material

A technology of surface surfacing and welding materials, which is applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., and can solve the problems of development and application of surface surfacing materials that are not resistant to cavitation corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 of the present invention: a cavitation-resistant surfacing material, its specific chemical composition is: C0.05%; Cr13%; Co1.0%; Mo1.5%; Ni6.0%; Mn0.5% ; Si0.3%; P≤0.03%; S≤0.03%; the balance is Fe. Surfacing welding is carried out for 1Cr18Ni9Ti, a commonly used material for turbine blades. Before welding, the surfacing surface is polished with metallographic sandpaper, cleaned with acetone, and then the surface is welded with MIG. The welding parameters are: welding voltage U=25.4V, welding current I=200A, shielding gas flow rate of 18L / min, welding The speed is 5mm / s. After surfacing welding, the cavitation corrosion test is carried out with JY98-IIIDN ultrasonic cell pulverizer, the vibration frequency is 20kHz, the medium is distilled water, and the cooling water temperature is controlled at 21°C. The microscopic observation of the cavitation corrosion site shows that: using the surfacing material with this composition for MIG surface welding, the n...

Embodiment 2

[0024] Embodiment 2 of the present invention: a cavitation-resistant surfacing material, its specific chemical composition is: C0.05%; Cr15%; Co1.2%; Mo1.5%; Ni6.5%; Mn0.5% ; Si0.5%; P≤0.03%; S≤0.04%; the balance is Fe. Surfacing welding for 1Cr18Ni9Ti material. Before welding, the surfacing welding surface was ground and cleaned with acetone, and then MIG was used for surface welding. The welding parameters and cavitation corrosion test parameters were the same as those in Implementation 1. The microscopic observation of the cavitation corrosion site shows that: using the surfacing material of this composition for MIG surface welding, the number of cavities in the surfacing layer is small, and the size of the cavities is smaller than that of Example 1.

Embodiment 3

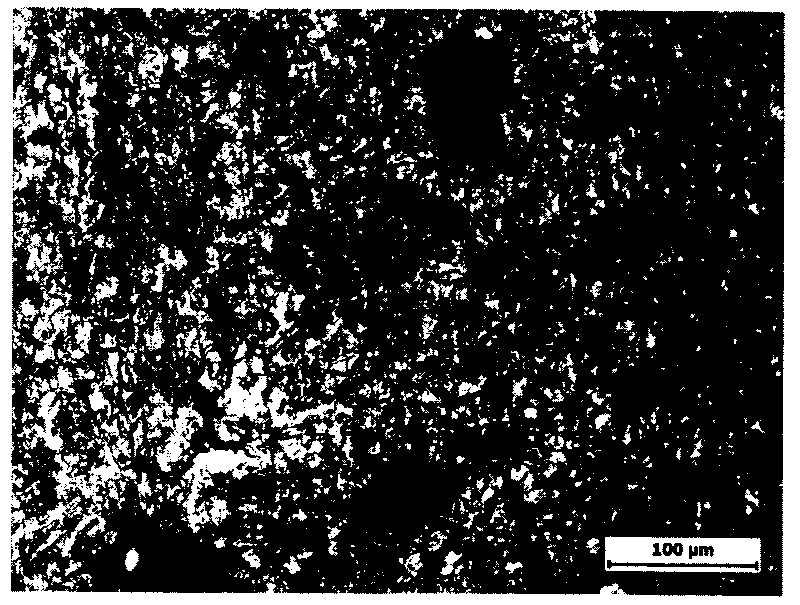

[0025] Embodiment 3 of the present invention: a cavitation-resistant surfacing welding material, its specific chemical composition is: C0.07%; Cr17%; Co1.5%; Mo1.8%; Ni7.0%; Mn0.8% ; Si0.5%; P≤0.03%; S≤0.03%; the balance is Fe. Surfacing for 1Cr18Ni9Ti. Before welding, the surfacing welding surface was ground and cleaned with acetone, and then MIG was used for surface welding. The welding parameters and cavitation corrosion test parameters were the same as those in Implementation 1. The microscopic observation of the cavitation corrosion site shows that: using this composition of surfacing material for MIG surface welding, the number of cavitation in the surfacing layer is small, and the size is also small, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com