Ultrasonic wave and pressure rotary atomizer

A rotary atomizer and ultrasonic technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of high injection pressure, small diameter of mist droplet, etc., and achieve the effect of overcoming the pressure bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

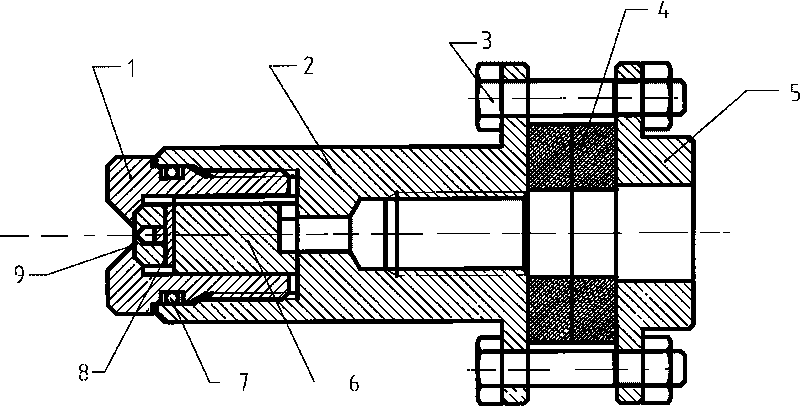

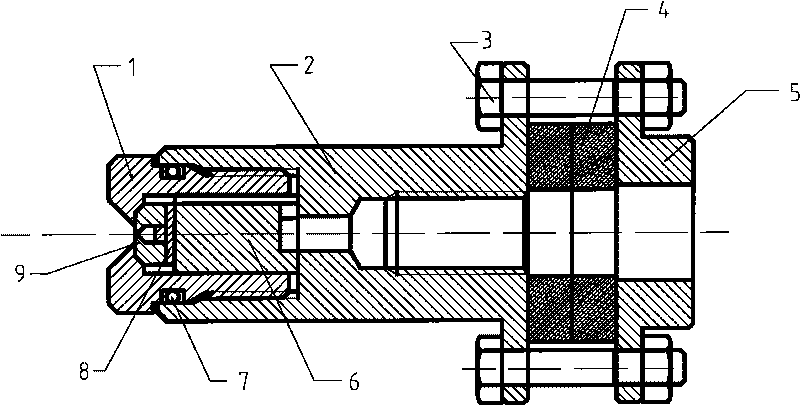

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] combine figure 1 and figure 2 . The atomizing nozzle of the present invention includes two parts: an ultrasonic transducer and a pressure rotating liquid nozzle; the ultrasonic transducer includes a transducer rear cover 5, pre-tightening bolts and nuts 3, a piezoelectric crystal 4 and a nozzle front cover 2; The pressure rotating liquid nozzle includes a flow guide 6 , a gasket 8 , a swirl 9 and a nozzle head 1 . The swirl chamber located in the middle of the swirl member 9 has a tapered tapered flow channel, and a diversion hole is opened on its side, and the opening direction is vertically tangent to the wall surface of the swirl chamber. The opening method is to open a large hole first and then a small one. Holes, the number of diversion holes is 1-4, evenly distributed on the side of the swirl piece.

[0024] The drain piece 6 is grooved on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com