Blast furnace first slag experiment method and first slag experimental furnace

An experimental method and experimental technology, applied in the directions of furnaces, furnace types, material inspection products, etc., can solve the problems of difficult to collect primary slag research, unsatisfactory results, and high cost, and achieve low cost, simple structure and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

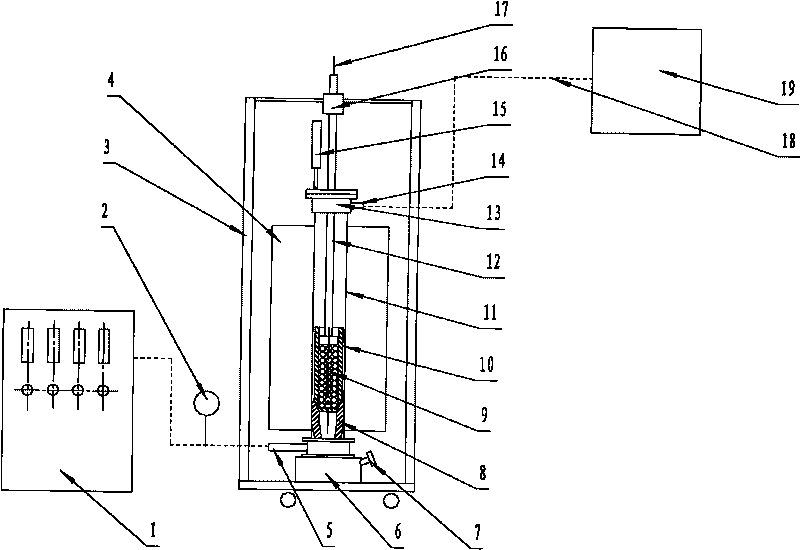

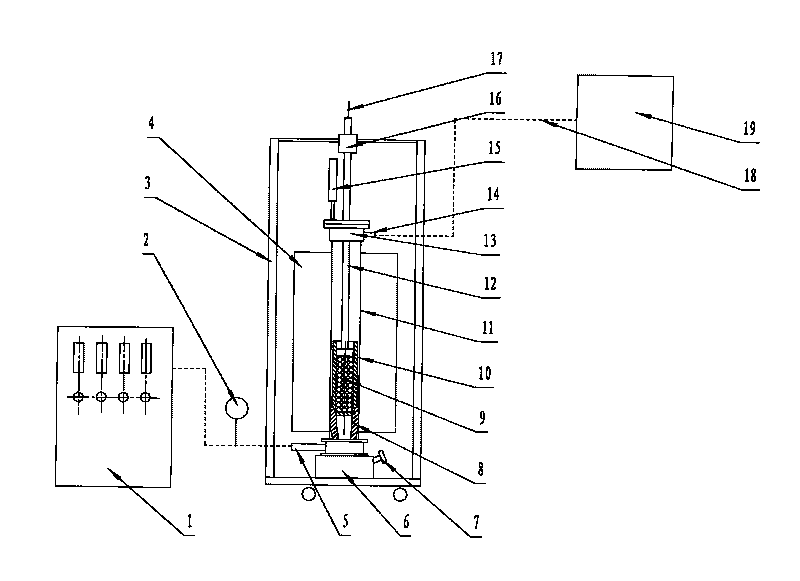

[0032] The following is a further explanation of the primary slag experimental furnace in conjunction with the accompanying drawings:

[0033] refer to figure 1 , comprising an electric furnace 4 and a gas distribution cabinet 1 provided with a hearth tube 11 installed on a support frame 3, the hearth tube 11 is provided with a graphite crucible 10 on a graphite base 8, and the upper end of the graphite crucible 10 is provided with a central pressing rod 12. The upper end of the central pressure rod 12 passes through the furnace tube 11 and is inserted with a thermocouple 17. The central pressure rod 12 in the furnace tube 11 is connected with a hydraulic cylinder 16. The upper end of the furnace tube 11 is provided with a cover 13 and a row The gas port 14 and the displacement sensor 15, the lower end is provided with a material receiving box 6, and the reducing gas inlet 5 is connected to the gas distribution cabinet 1, and a pressure differential transmitter is installed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com