Method for preparing high-resolution emitter tungsten tip and device thereof

A high-resolution, emitter technology, applied in the direction of measuring devices, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of increasing the emission threshold voltage, the difficulty of emitter needle tip, and the inapplicability of liquid metal ion source needle tip, etc., to achieve the preparation The method is simple, the surface morphology is excellent, and the production cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

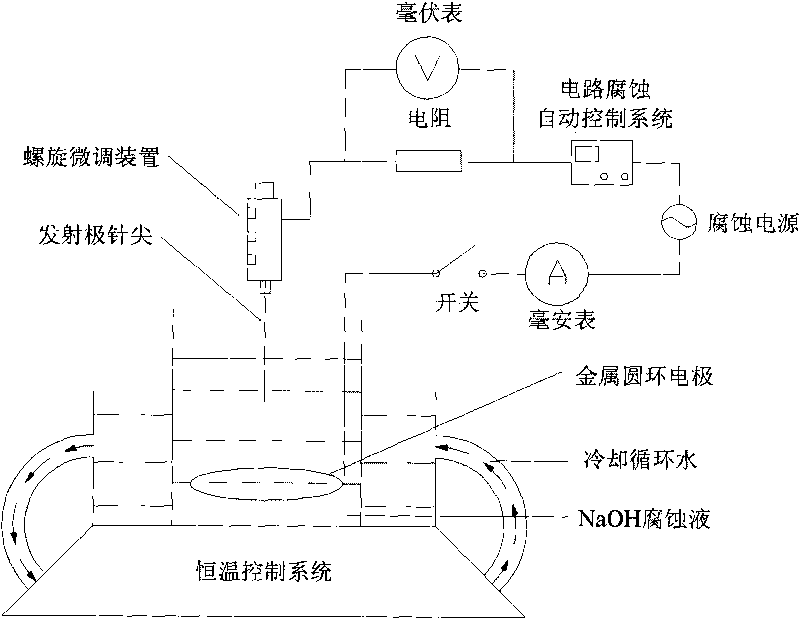

[0029] Accurately prepare a certain concentration of corrosion solution, according to the mass percentage, the composition of the corrosion solution is 10% of saturated NaOH and 90% of deionized water. Put the corrosive liquid in the cooler for low-temperature cooling, take it out when it reaches 5°C, fix it horizontally in the constant temperature controller, adjust the constant temperature control system, and maintain the temperature of the corrosive liquid at a constant temperature.

[0030] Take a piece of W wire with a length of 18 mm and a diameter of 0.18 mm, and after hydrogen flame annealing at 780 ° C, completely remove its surface oxide layer, and fix one end of the prepared W wire on the screw fine adjustment device.

[0031] Take the special Kovar metal wire as the metal ring electrode, process it to make it a standard circle, connect it with a wire and fix it on the support of the corrosion system as the auxiliary electrode, and connect it with the auxiliary elect...

Embodiment 2

[0036] Accurately prepare a certain concentration of corrosion solution, according to the mass percentage, the composition of the corrosion solution is 20% of saturated NaOH and 80% of deionized water. Put the corrosive liquid in the cooler for low-temperature cooling, take it out when it reaches 7°C, fix it horizontally in the constant temperature controller, adjust the constant temperature control system, and keep the temperature of the corrosive liquid at a constant temperature.

[0037] Take a section of W wire with a length of 30 mm and a diameter of 0.18 mm, and after hydrogen flame annealing at 780 ° C, completely remove its surface oxide layer, and fix one end of the prepared W wire on the screw fine adjustment device.

[0038] Take the special Kovar metal wire as the metal ring electrode, process it to make it a standard circle, connect it with a wire and fix it on the support of the corrosion system as the auxiliary electrode, and connect it with the auxiliary electro...

Embodiment 3

[0043] Accurately prepare the corrosion solution with a certain concentration. According to the mass percentage, the composition of the corrosion solution is 30% saturated NaOH and 70% deionized water. Put the corrosive liquid in the cooler for low-temperature cooling, take it out when it reaches 10°C, fix it horizontally in the constant temperature controller, adjust the constant temperature control system, and maintain the temperature of the corrosive liquid at a constant temperature.

[0044] Take a section of W wire with a length of 50 mm and a diameter of 0.22 mm, and after hydrogen flame annealing at 780 ° C, completely remove its surface oxide layer, and fix one end of the prepared W wire on the screw fine adjustment device.

[0045] Take the special Kovar metal wire as the metal ring electrode, process it to make it a standard circle, connect it with a wire and fix it on the support of the corrosion system as the auxiliary electrode, and connect it with the auxiliary el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com