Ice medlar wine and brewing method thereof

A technology of ice qi and qi fruit is applied in the fields of food processing and microbial fermentation, which can solve the problems of insufficient wine body, insufficient extraction, destruction of effective components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

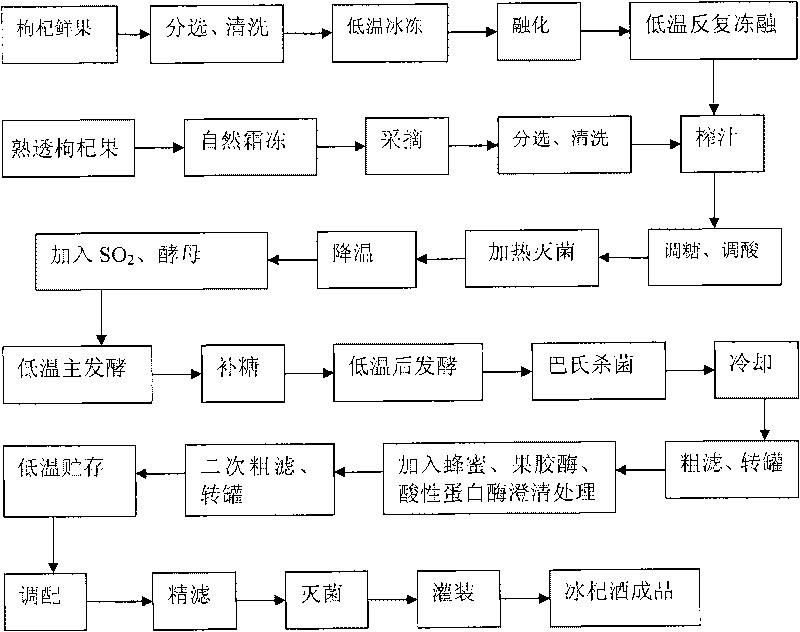

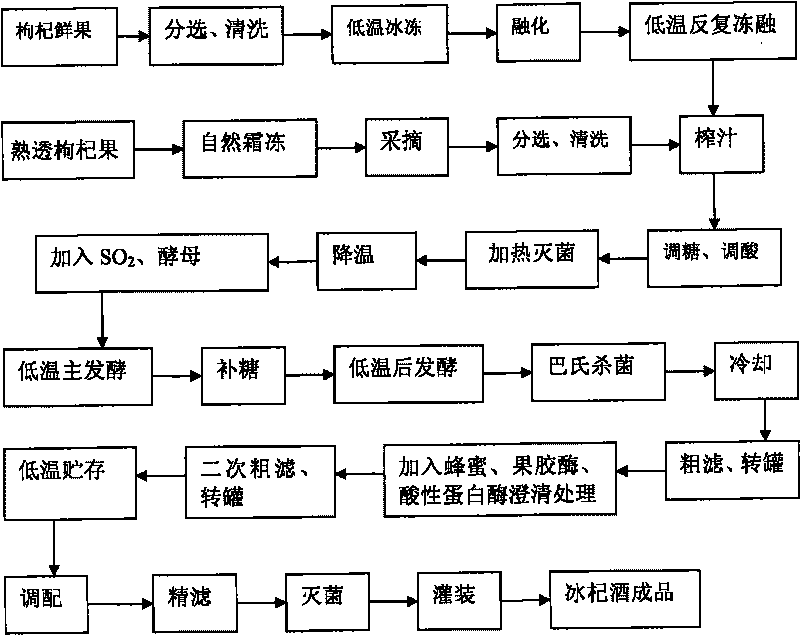

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: dry type iceberry fruit wine (natural freezing brewing method)

[0035] (1) Pick 1000 kg of ice wolfberry fruit after natural frost at -6~-10℃;

[0036] (2) ice wolfberry fruit sorting, cleaning;

[0037] (3) Squeeze the ice wolfberry fruit, wash the pomace with 200 liters of pure water, and incorporate the washing solution into the fruit juice to produce a total of 800 liters of fruit juice. Add 75 grams of sodium sulfite to the juice to make the SO2 content reach 40-50 mg / L;

[0038] (4) Adjust the sugar content of the juice to 220-240g / L with white sugar, and adjust the acidity to 4.5-5.5g / L with citric acid;

[0039] (5) Heat the juice to 70°C, keep it warm for 30 minutes, and cool down to 20-22°C;

[0040] (6) Add 300 g of wine-making active dry yeast into 30 liters of 38-42°C water for rehydration and activation for 40 minutes, put it into fruit juice, and carry out 10-15 days of normal-pressure airtight main fermentation at a temperature of 20-25...

Embodiment 2

[0056] Embodiment 2: semi-sweet ice berry fruit wine (the brewing method of Lycium barbarum freeze-thaw repeatedly)

[0057] (1) Picking 1000 kilograms of ripe wolfberry fresh fruit, selection;

[0058] (2) Wash the wolfberry fruit, and then freeze it at -10 to -15°C for 24 hours. Thaw at a low temperature of 3-5°C for 24 hours, freeze and thaw again, and repeat this process 3 times.

[0059] (3) Squeeze the frozen wolfberry fruit, wash it with 200 kg of pure water, and incorporate the washing liquid into the juice to produce a total of 800 liters of fruit juice. Add 75 grams of sodium sulfite to the juice to make the SO2 content reach 40-50 mg / L;

[0060] (4) Adjust the sugar content of the juice to 220-240g / L with white sugar, and adjust the acidity to 4.5-5.5g / L with citric acid;

[0061] (5) Heat the juice to 70°C, keep it warm for 30 minutes, and cool down to 20-22°C;

[0062] (6) Add 300g of active dry yeast for winemaking to 30 liters of water at 38-42°C for rehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com