Efficient scale inhibitor of tail-gas compressor of styrene device and application method thereof

A technology of tail gas compressor and antiscalant, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~27

[0017] Under constant stirring, by mass, in commercially available 2# solvent (commercial brand, main component is hydrocarbons), add each compound component that table 1, table 2 and table 3 provide respectively, make it mix homogeneously, That is, the tail gas compressor scale inhibitor of the present invention is obtained. Measured according to the method specified in GB / T265, the kinematic viscosity of the scale inhibitor is 1-5 at 40°C.

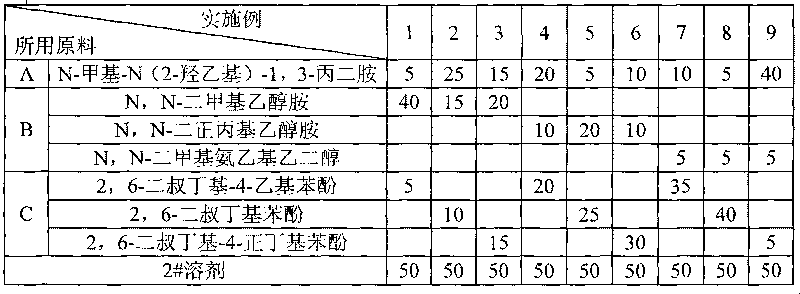

[0018] Table 1: Components and ratios of scale inhibitors for high-efficiency compressors in Examples 1 to 9 (data in the table are all parts by mass)

[0019]

[0020] Table 2: Components and ratios of scale inhibitors for high-efficiency compressors in Examples 10 to 18 (data in the table are all parts by mass)

[0021]

[0022] Table 3: Components and ratios of scale inhibitors for high-efficiency compressors in Examples 18 to 27 (data in the table are all parts by mass)

[0023]

Embodiment 28

[0025] Add the high-efficiency scale inhibitor for tail gas compressor of Example 1 into the mixed hydrocarbons composed of 100g styrene, α-methylstyrene and vinylbenzene (mass fraction is respectively 50%, 20%, 30%) at 2000ppm and Placed in a closed stainless steel container with a volume of 2L, reacted at a temperature of 120°C, a pressure of 2.5MPa, and a residence time of 48h. After the reaction, the mass of the polymer produced was measured to be 5.891g.

Embodiment 29

[0027] The tail gas compressor high-efficiency scale inhibitor of example 2 is added in the mixed hydrocarbon that is made up of 100g styrene, α-methylstyrene, vinylbenzene (mass fraction is respectively 50%, 20%, 30%) by 1800ppm and Placed in a closed stainless steel container with a volume of 2L, reacted at a temperature of 120°C, a pressure of 2.5MPa, and a residence time of 48h. After the reaction, the mass of the polymer produced was measured to be 5.973g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com