Manufacture method of MEMS packaged glass microcavity with optical window

A technology for encapsulating glass and optical windows, used in optics, manufacturing tools, manufacturing microstructure devices, etc., can solve the problems of surface roughness of glass microcavities, difficult to achieve surface roughness of optical devices, and poor bottom surface roughness of glass microcavities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for manufacturing a wafer-level glass microcavity, comprising the following steps:

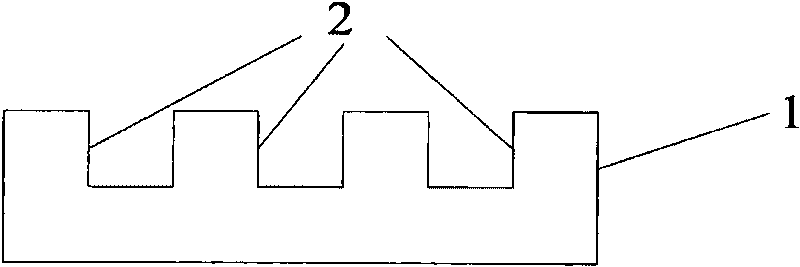

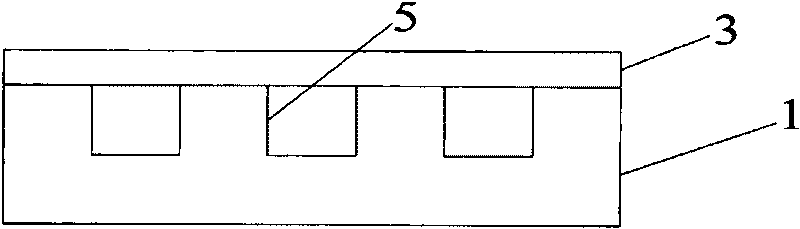

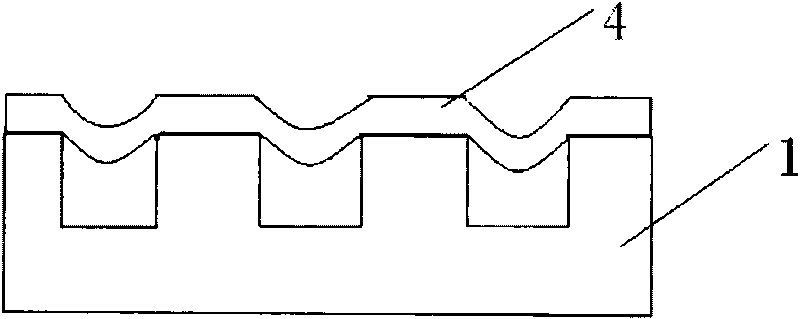

[0029] In the first step, a specific microgroove pattern is formed by etching on a Si wafer (such as a 4-inch wafer) using a Si micromachining process. The micromachining process of the pattern structure on the Si original sheet is a wet etching process or a dry induction process. One of the coupled plasma (ICP) etching process, reactive ion etching or deep reactive ion etching, the pattern can be a square or circular groove array, or a number of different graphics, (actually three-dimensional Look, engraving a specific pattern is to carve a groove on a silicon wafer, which is a pattern in two dimensions), and the aspect ratio of the microgroove can be less than 1:1 or greater than 1:1, for example: 2:1, 3:1, 4 : 1, 7: 1, 10: 1, 15: 1, 20: 1, glass microcavities with large aspect ratio will provide more rheological space for the glass, thus providing more options for the size o...

Embodiment 2

[0035] A method for manufacturing a wafer-level glass microcavity, comprising the following steps:

[0036] The first step is to etch a specific pattern on a 4-inch Si wafer by using deep reactive ion etching (in fact, in three dimensions, it is a groove on the silicon wafer, and in two dimensions, it is a pattern). The pattern is a square groove array , the aspect ratio of the pattern is 20:1, the silicon wafer is polished,

[0037] In the second step, the above-mentioned Si wafer and the (4 inches) Pyrex7740 glass wafer of the same size (a brand of borosilicate glass, produced by Corning-corning in the United States, available in the market, have been polished) in an atmosphere of 1000Pa The bonding is carried out on the EVG-501 anode bonding machine, so that the above-mentioned specific pattern on the Pyrex7740 glass forms a sealed cavity, and the bonding surface is routinely cleaned and polished according to the requirements of anodic bonding before bonding to maintain a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com