Blanking method and system thereof

A blanking and feeding technology, which is applied in the field of blanking method and its system, can solve the problems of standard density error, irregular cross-sectional shape, large weight deviation, etc., and achieve the effect of improving the accuracy of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

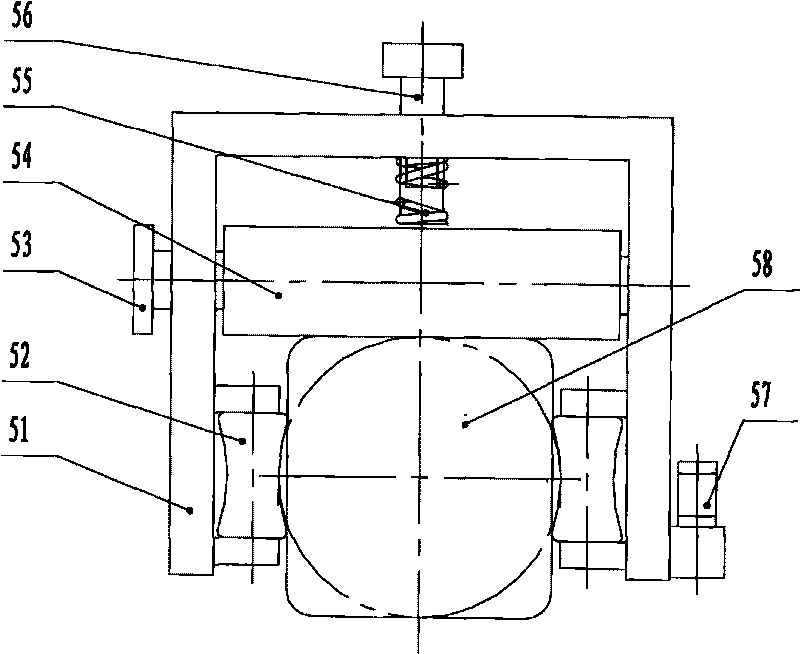

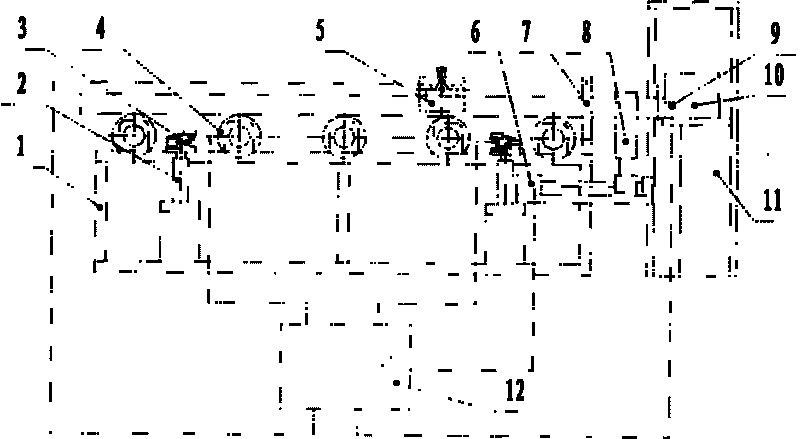

[0028] Such as figure 1 , figure 2 Shown:

[0029] The material is placed on the roller 4 of the feeding frame 1, and the two weighing cylinders 2 are stretched out at the same time, driving the weighing module 3 to lift the material for weighing. Of course, other forms of weighing can also be used here, and the weighing is completed. Finally, the oil cylinder descends, the material is put back on the feeding roller 4, and the length measuring device 5 starts to measure the total length of the material. After the length is measured, the feeding chuck 8 is driven by the feeding servo device 6 to send the material to the sawing chuck The initial position of the outer end surface of 10 is detected and positioned by the position sensor 9 installed on the outer end surface of the feeding chuck to ensure that the end of the material is close to the outer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com