Wave-soldering unit and mechanical gripper thereof

A technology of wave soldering and mechanical claws, applied in the direction of manipulators, welding equipment, auxiliary devices, etc., can solve problems such as workpiece deformation, uneven force applied to clamping points, and workpiece damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

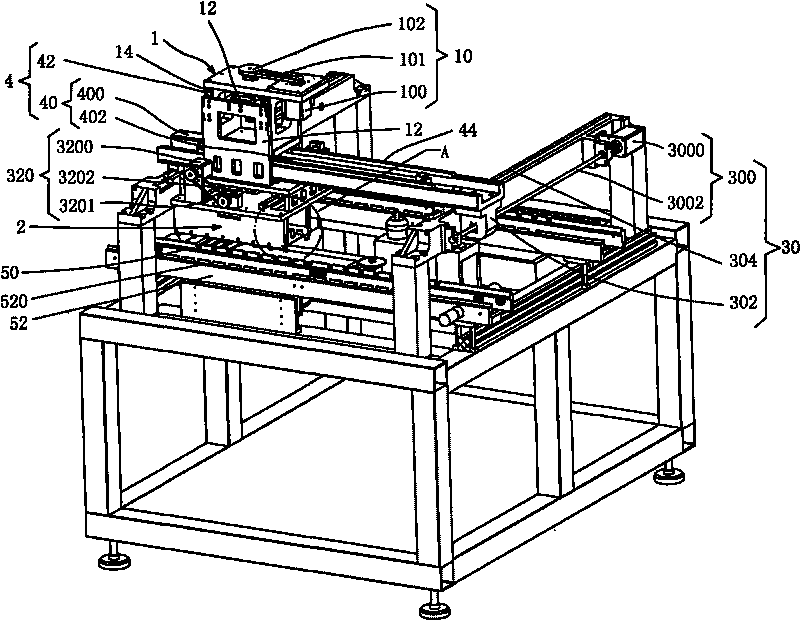

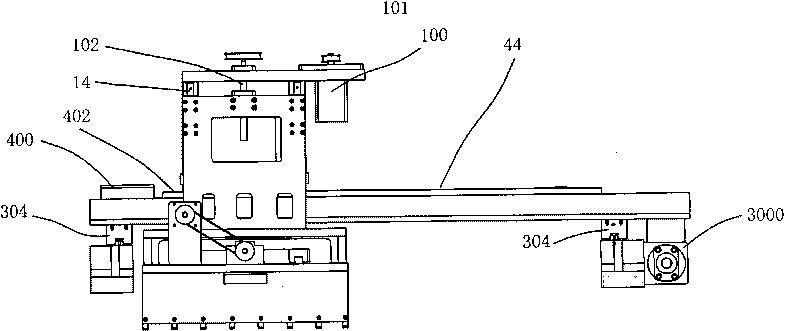

[0025] Such as figure 1 As shown, the present invention provides a mechanical claw of a wave soldering machine, including a lifting displacement device 1, a pair of claw bodies 2 driven up and down by the lifting displacement device 1, and a mechanism for driving the pair of claw bodies 2 to realize the opening and closing action. Zhanghe system.

[0026] Wherein, the lifting displacement device 1 includes a lifting power mechanism 10 and a lifting base 12 driven by the lifting power mechanism 10 to move up and down along a lifting axis (ie, a Z axis).

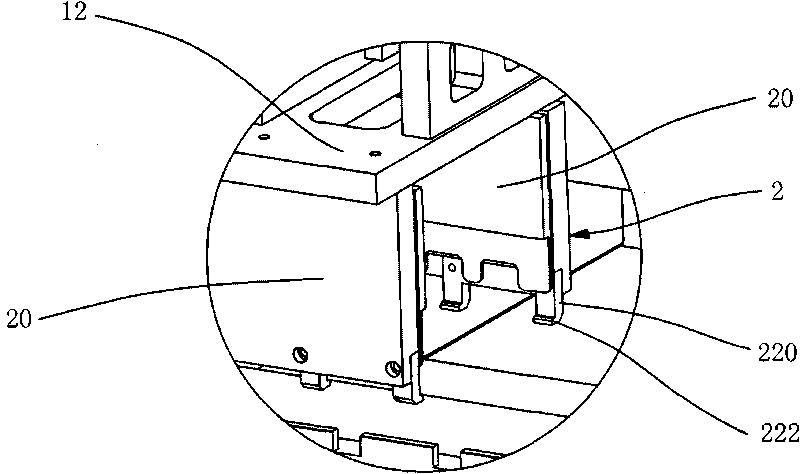

[0027] combine figure 2 As shown, the two claws 2 are arranged facing each other, and each claw 2 includes a base 20 and at least one protruding from the bottom edge of the base 20 toward the other claw 2 for supporting the workpiece from the bottom. minions22. The claw 22 includes an extension 220 connected to the base 20 and a supporting portion 222 bent from the end of the extension 220 toward the other claw 2 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com