Palm-joint glue spreading method and device of film label

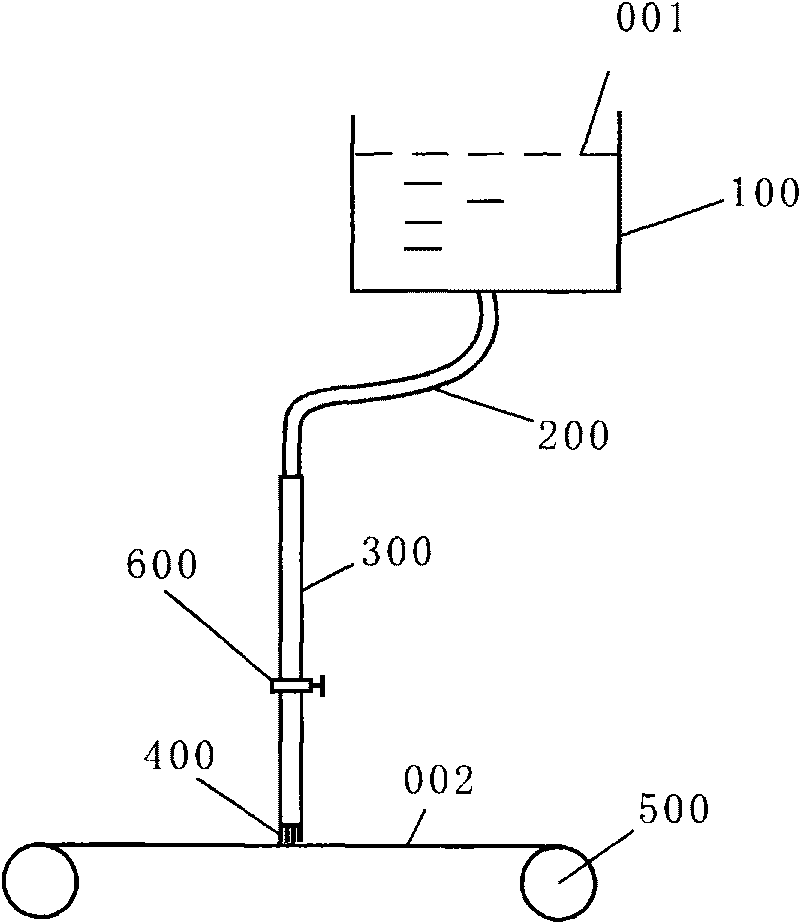

A gluing device and labeling technology, which is applied in the gasshang gluing of film labels and the gasshang field of film labels, which can solve the problems of the gasshang machine 500 running speed is not very stable, the amount of glue applied is not very stable, and the running speed is slow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

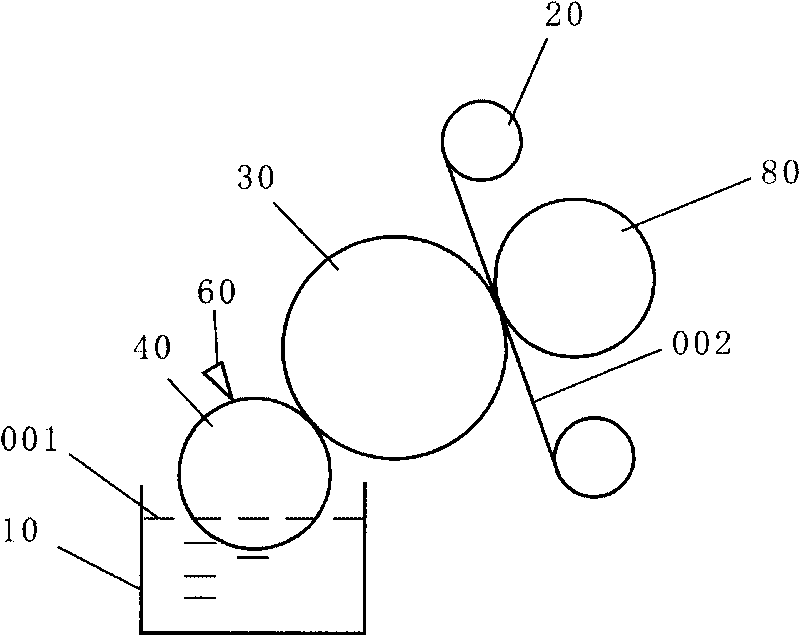

[0028] In this embodiment, the glue is printed on the film label by the flexo printing process, such as image 3 As shown, the gluing device includes a glue tank 10 , a clasping machine 20 , a flexo plate roller 30 , an embossing roller 80 , an anilox roller 40 and a scraper 60 .

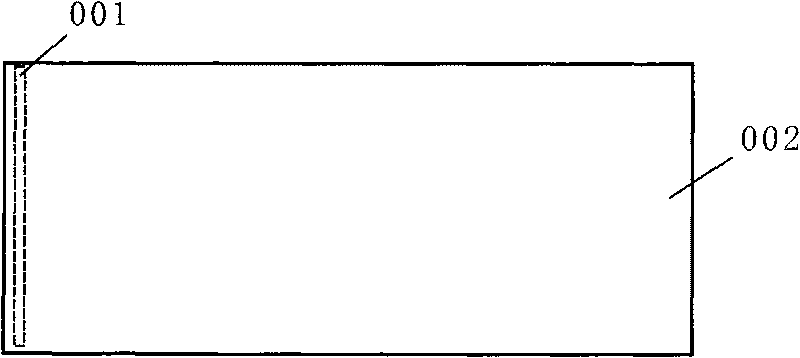

[0029] Wherein the anilox roller 40 is partly immersed in the glue tank 50, the surface of the anilox roller 40 is in tangential contact with the flexographic printing plate roller 30, and the flexographic printing plate roller 30 and the embossing roller 80 sandwich the film label conveyed by the palm machine 20 002, the doctor blade 60 is installed on the surface of the anilox roller 40. Another example Figure 4 As shown, after the flexographic printing plate roll 30 is unfolded, there is a raised strip stamp 31 with a width of 0.5-2.5mm on it. The strip stamp 31 is a continuous linear stamp, preferably with a width of 1mm. Such a die prints the glue in a straight line running along the edge of...

Embodiment 2

[0032] In this embodiment, the glue is printed on the film label by the gravure printing process, such as Figure 5 As shown, the gluing device includes a glue tank 10 , a clasping machine 20 , an embossing roller 80 , a gravure printing plate roller 70 and a scraper 60 .

[0033] Wherein, the gravure printing plate roller 70 is partly immersed in the glue tank 10 , and sandwiches the film label 002 transported by the clasping machine 20 with the embossing roller 80 , and the scraper 60 is installed on the surface of the gravure printing plate roller 70 . After the gravure printing plate roll 70 unfolds, has such as Figure 4 In the shown structure, only because it is gravure printing, the strip-shaped stamp 31 does not protrude outward but is recessed inward.

[0034] The working mode of the gluing device of this embodiment is: the gravure printing plate roller 70 transfers the glue 001 in the glue tank 50 to the film label 002, and in this process, the effect of the scraper...

Embodiment 3

[0036] The difference between this embodiment and the above two embodiments is that the strip stamp 31 is a dot stamp, so that the glue printed on the edge is arranged in discontinuous dots, as Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com