Traditional Chinese medicine extract drying method for preparing drug for curing osteoporosis

A technology of osteoporosis and drying method, which is applied in the direction of drug combination, pharmaceutical formula, bone diseases, etc., can solve the problems of large consumption of human, financial and material, unfavorable drug sales, and reduced enterprise benefits, etc., and achieves easy automatic control, convenient Continuous production, optimal social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

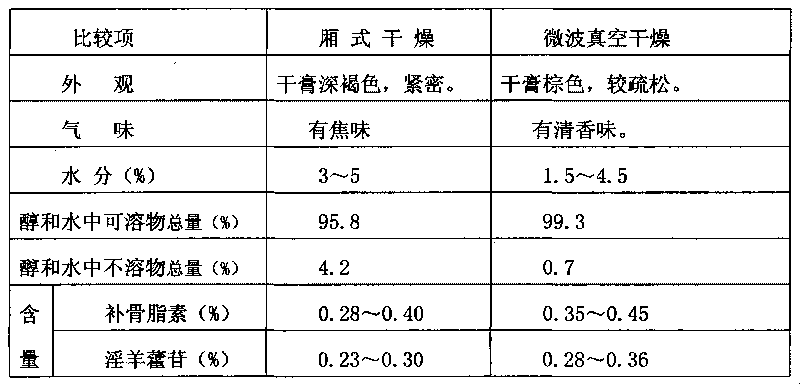

Image

Examples

Embodiment 1

[0027] (1). Ingredients: 583.5 parts by weight of psoralen; 583.5 parts by weight of Herba Epiphyllum; 417 parts by weight of medlar; 417 parts by weight of Ligustrum lucidum; parts by weight.

[0028] (2). According to the above-mentioned dosage and ratio of the seven medicinal materials, drynariae are scalded.

[0029] (3). Soak psoraleae and privet fruit in an ethanol solution with a concentration of 80% for about 2 hours, reflux and extract twice at 80°C, and add 10 times the concentration of the medicinal materials for the first time to 80% Extract with ethanol solution for 2.5 hours, add 8 times the concentration of medicinal materials for the second time and extract with 80% ethanol solution for 2 hours, combine the two alcohol extracts, reclaim ethanol at 70~80°C and concentrate to a relative density of 1.35~1.40g / ml ( 80~90℃) extract A, set aside.

[0030] (4). Combine the five herbs of Epimedium, Lycium barbarum, Rhizoma Drynariae, Gouji, and Achyranthes bidentata ...

Embodiment 2

[0033] (1). Ingredients: 583.5 parts by weight of psoralen; 583.5 parts by weight of Herba Epiphyllum; 417 parts by weight of medlar; 417 parts by weight of Ligustrum lucidum; parts by weight.

[0034] (2). Weigh the Qiwei herbs according to the prescription, and scald the Rhizoma Rhizoma Rhizoma Rhizome.

[0035] (3). Soak the medicinal materials Psoralen and Ligustrum lucidum in 75% ethanol solution for about 4 hours, reflux extraction at 82°C twice, add 10 times the medicinal materials for the first time and extract 2.5% in 75% ethanol solution hour, the second time add 8 times the concentration of the medicinal material and extract with 75% ethanol solution for 2 hours, combine the alcohol extract, reclaim the ethanol and concentrate it to the extract A with a relative density of 1.35~1.40 ((80~90°C measurement)), set aside .

[0036] (4). Combine the five medicinal materials of Epimedium, Lycium barbarum, Drynaria tangensis, Gouji, and Achyranthes bidentata, with the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com