Pole core press mounting device of generator rotor of hydro-power generating unit

A technology for generator rotors and pole cores, which is applied in the manufacture of stator/rotor bodies, etc., which can solve problems such as intractable pole cores that cannot meet the tightness requirements and pressure transmission, so as to improve quality and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

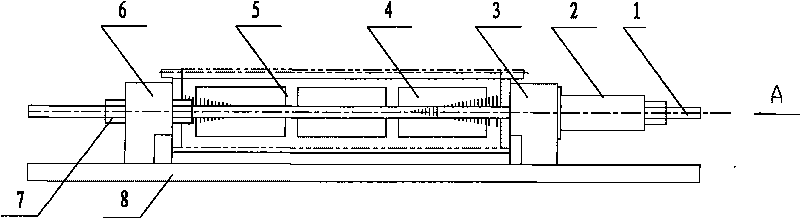

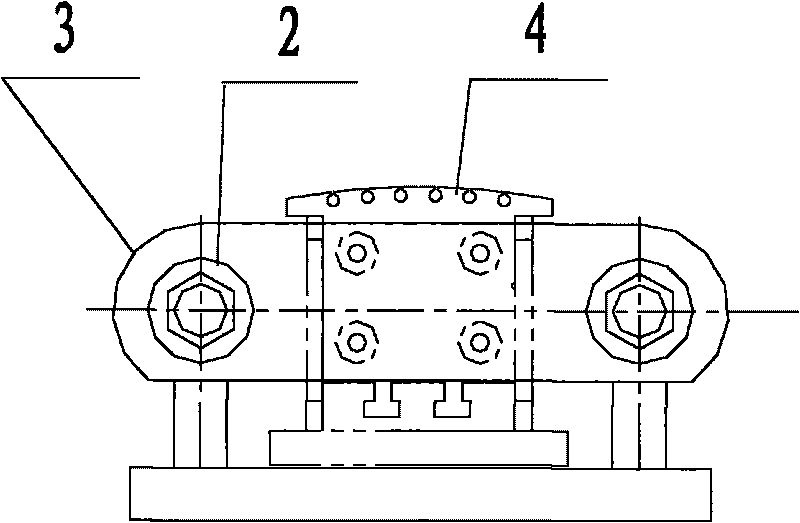

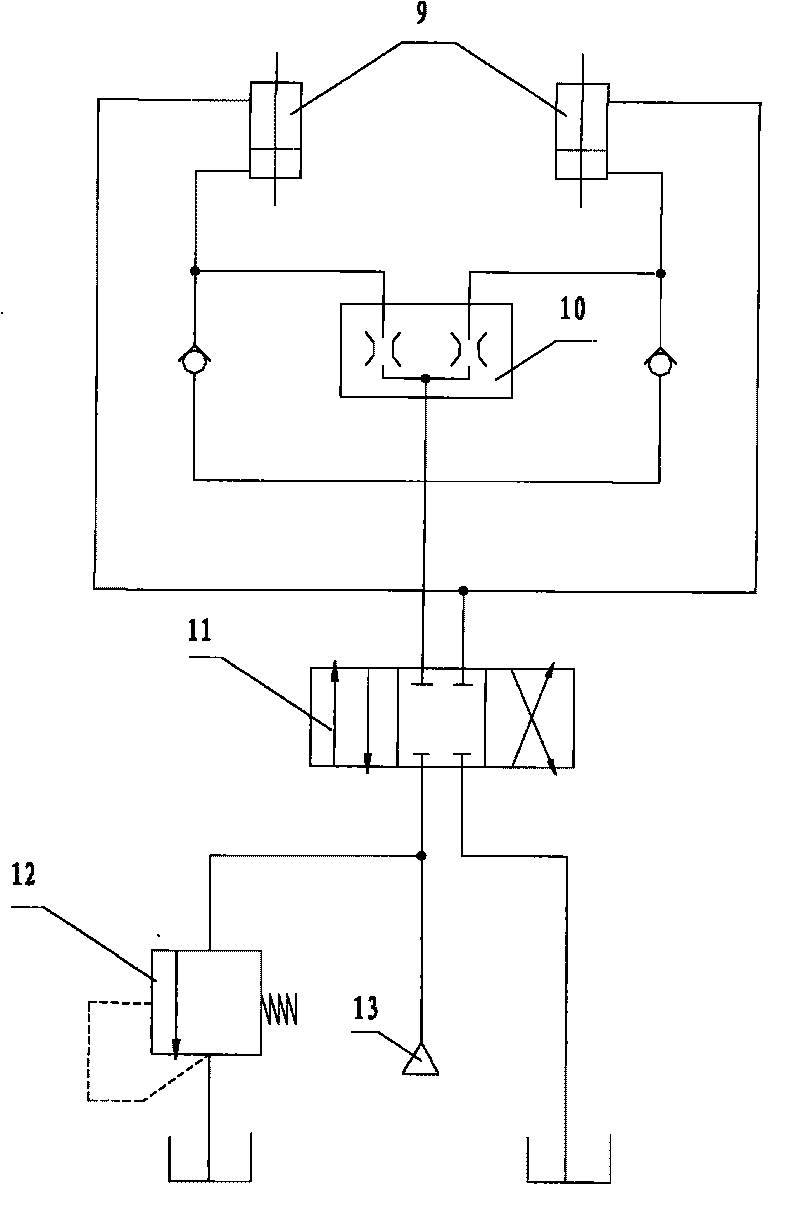

[0021] A generator rotor magnetic pole core press-fitting device for a hydroelectric unit, comprising a chassis 8, a piston rod 1, a front support 3, a rear support 6, a stretching oil cylinder 2, a nut 7 and a hydraulic transmission system, and a pre-stacking of magnetic pole punching pieces Frame 5, on the support, the stretching oil cylinder is arranged on both sides of the magnetic pole punching piece 4, and the hydraulic transmission system is a hydraulic transmission mechanism of two stretching oil cylinders 2 synchronous movements and a mechanical transmission mechanism of two stretching oil cylinders synchronous movement. The hydraulic transmission mechanism is equipped with a synchronous distribution valve 10, an electromagnetic reversing valve 11, a pressure regulating valve 12, and a hydraulic pump 13 that supply the oil pressure and flow of the two stretching cylinders 9, which can accurately supply the oil pressure of the two stretching cylinders. pressure and flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com