Two-way single-mode ramp type tower-shaped linear ultrasonic motor and electric excitation method

A linear ultrasonic motor, single-mode technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of narrow frequency range and energy loss of the motor. Increase, affect the motor operating efficiency and performance, etc., to achieve the effect of miniaturization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

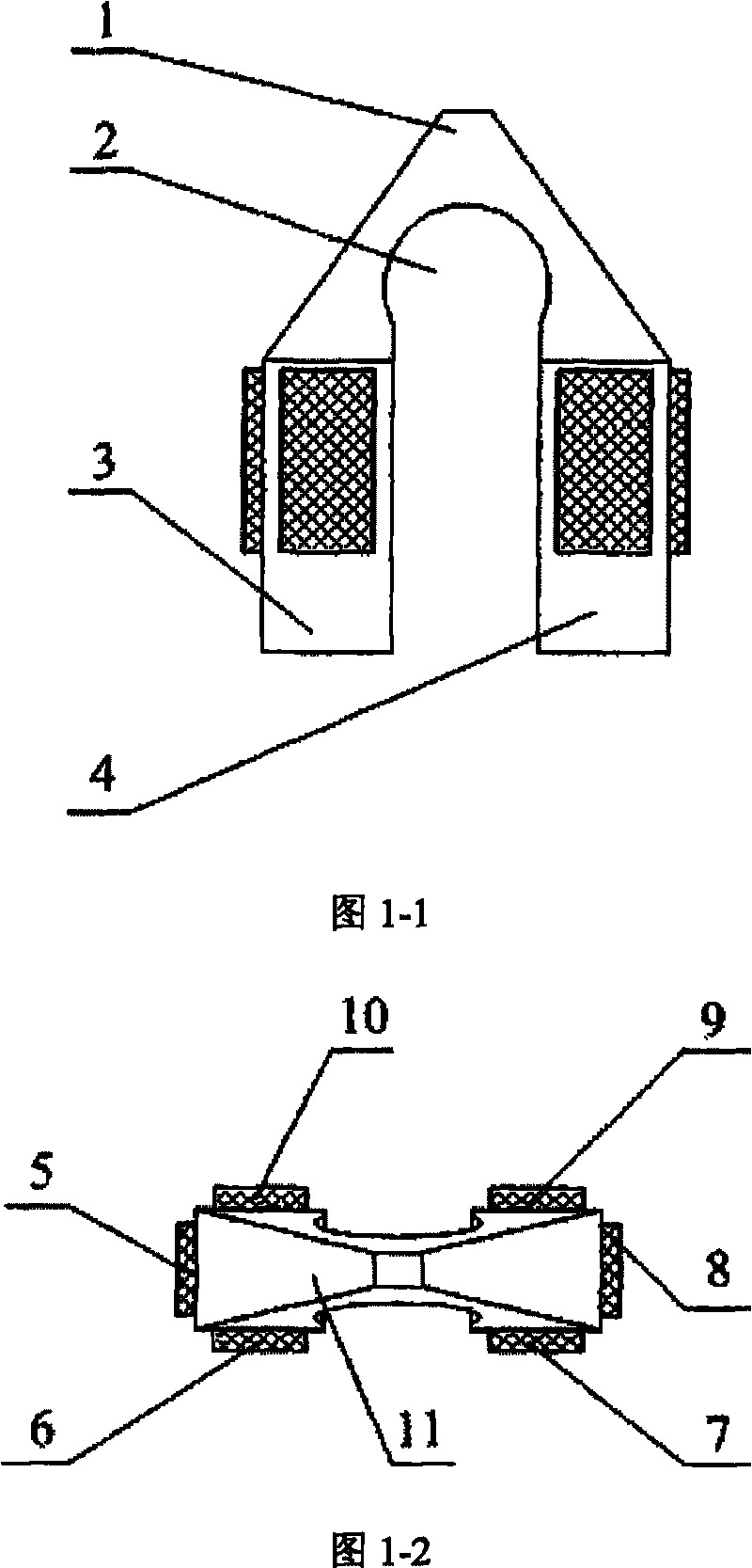

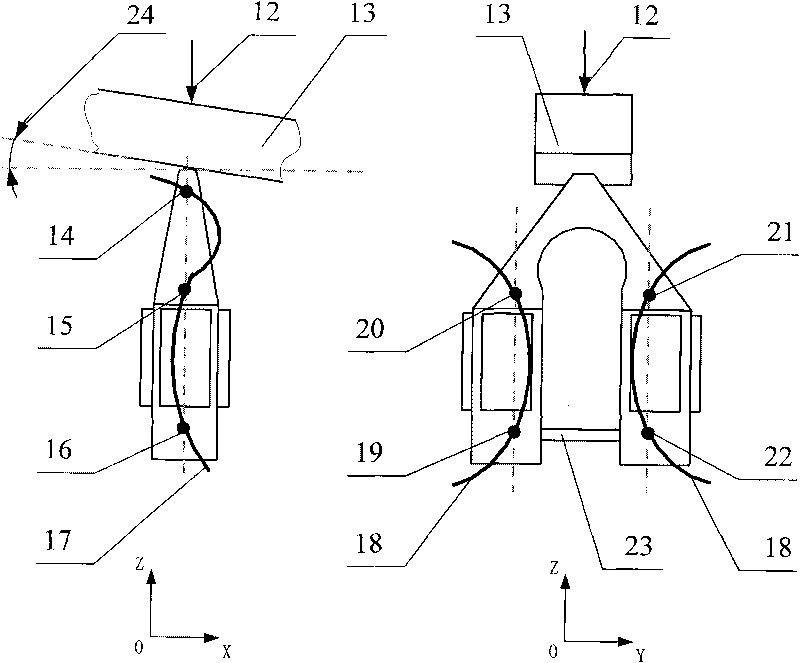

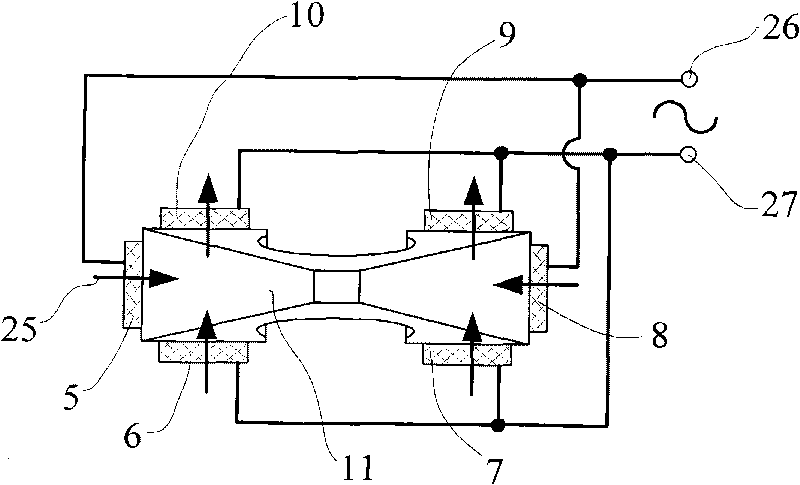

[0028] A linear motion ultrasonic motor such as Figure 2 As shown, it is composed of a stator and a guide rail. The guide rail has an inclination angle of θ degree 24, and is pressed on the stator by a preload 12. The stator is composed of figure 1 shown. Its characteristics: the stator is composed of a tower-shaped metal body 11 with a driving foot 1, a flexible enlarged round hole 2 and two rectangular columns 3, 4. The outer surface of the tower-shaped metal body 11 is symmetrically pasted with six pieces of pressure The electric ceramics 5, 6, 7, 8, 9, 10 are used to excite the vibration of the tower-shaped metal body 11. Such as Figure 3 Shown, among them, piezoelectric ceramics 6, 7, 9, 10 are used to excite the second-order bending vibration mode 17 of the tower stator in the x-z section; piezoelectric ceramics 5 and 8 are used to excite the tower stator in the y-z section with local bending Symmetrical modes of vibration18.

[0029] Apply y-z in-plane symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com