Multistage burner

A technology of stage combustion and combustion chamber, which is applied in the field of multi-stage burners, can solve the problems of excessive smoke and dust discharge, environmental protection, energy saving, insufficient combustion, etc., and achieve the effects of full combustion, improved service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

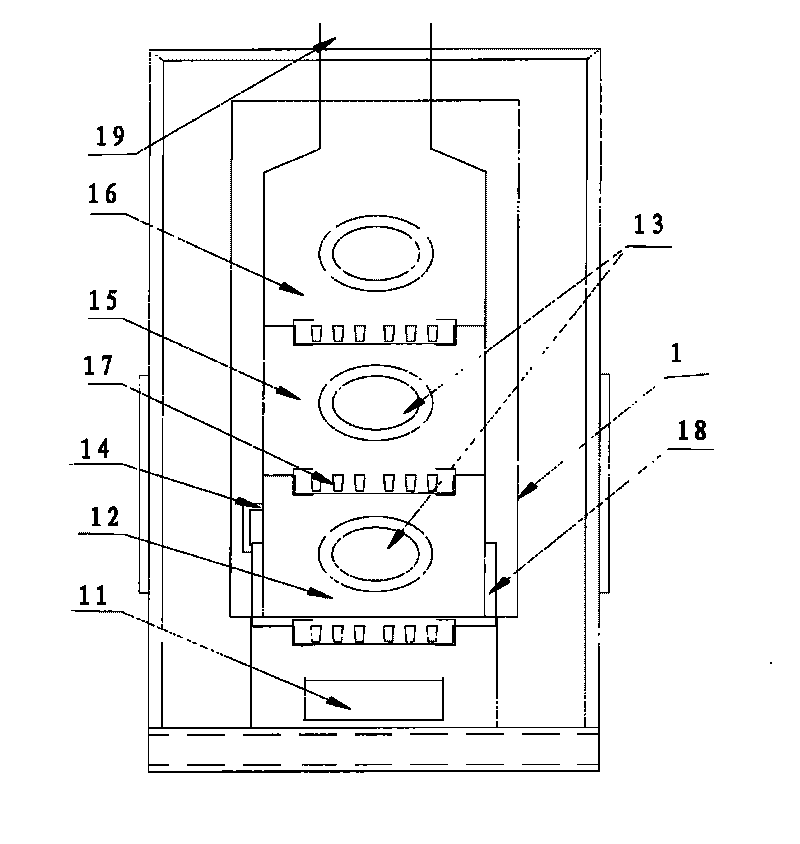

[0016] For the present invention, a preferred embodiment is now described in detail in conjunction with the drawings, as figure 1 Shown, the present invention comprises main body of furnace 1, combustion chamber, tail gas discharge port, wherein:

[0017] The main furnace body 1 is provided with a soot removal port 11 at its lower part, and above the soot removal port 11 is a primary combustion chamber 12, the primary combustion chamber 12 is located inside the main furnace body 1, and the main furnace body 1 is provided with a The air inlet (not shown) and the feeding port 13 of the combustion chamber 12 gas supply, supply combustion-supporting gas to the combustion chamber through the air inlet to make the fuel burn; carry out fuel addition through the feeding port 13, remove the fuel residue by the soot cleaning port 11; A secondary air inlet 14 is also provided on the body of furnace 1, and the air inlet 14 communicates with the primary combustion chamber, and is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com