Method and device for producing polysilicon by using plasma assisting fluidized bed process

A plasma and polysilicon technology, applied in chemical instruments and methods, silicon, inorganic chemistry, etc., can solve the problems of complex tail gas composition, small specific surface area of silicon rod deposition, energy consumption and power consumption, etc., to improve reaction efficiency and deposition rate , reduce equipment and maintenance costs, and improve production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

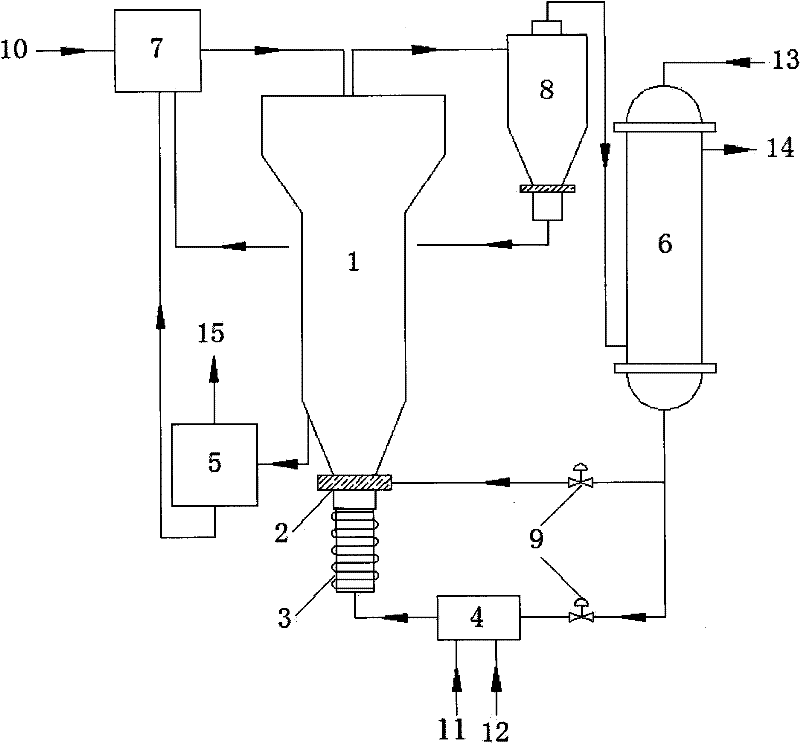

[0040] see figure 1 , figure 1 It is a schematic diagram of a preferred example of the device for producing polysilicon by the plasma-assisted fluidized bed process of the present invention. It includes a fluidized bed reactor 1 , a gas feeding device 2 , a plasma generating device 3 , a gas mixer 4 , a product sorting device 5 , a feed preheater 6 , a seed crystal feeding device 7 and a cyclone separator 8 .

[0041] The bottom of the fluidized bed reactor 1 is connected to a gas feeding device 2 and a plasma generating device 3 in sequence.

[0042] The feed preheater 6 is respectively connected with the gas feed device 2 and the gas mixer 4 through the flow regulating valve 9 , and the gas mixer 4 is connected with the plasma generator 3 . By adjusting the flow regulating valve 9, the feed gas 13 (silane and halosilane) can be preheated by the feed preheater 6 and then all enter the gas mixer 4, and hydrogen 11 and / or auxiliary gas 12 (helium, neon) gas, argon, krypton, ...

Embodiment 2

[0057] 1) The frequency of the plasma generator used is 40.68MHz and the power is 100kW.

[0058] 2) The air pressure in the plasma generator and the fluidized bed reactor is 1 bar.

[0059] 3) The raw material gas is a gas mixture of dichlorosilane and silicon tetrachloride with a volume ratio of 1:3, and all the raw gas is passed into the gas mixer with a flow rate of 10m 3 / h,

[0060] 4) When the device is started, the auxiliary gas (argon) is first introduced, and the flow rate (10m 3 / h), and turn on the plasma conversion device to purge and heat up the FBR. After the plasma is stable, gradually open the hydrogen regulating valve to feed in hydrogen, and reduce the flow of auxiliary gas. The hydrogen flow is finally adjusted to 30m 3 / h, the auxiliary gas flow rate is finally 3 ~ 5m 3 / h. Add seed crystals from the feeding port on the top of the FBR, and start to feed the raw material gas. After the pressure difference between the top and bottom of the FBR is stable,...

Embodiment 3

[0062] 1) The frequency of the plasma generator used is 40.68MHz and the power is 100kW.

[0063] 2) The air pressure in the plasma generator and the fluidized bed reactor is 0.95 bar.

[0064] 3) The raw material gas is pure silicon tetrachloride, and all the raw gas is passed into the gas feeding device with a flow rate of 7.5m 3 / h.

[0065] 4) The hydrogen flow rate is 30m 3 / h. Continuous and stable production for 100 hours, a total of about 100kg of seed crystals were input, about 260kg of products were obtained from the discharge port, the total output was about 160kg, and the unit power consumption was about 63kWh / kg. The tail gas is condensed, and the liquid phase contains about 35% trichlorosilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com