Three-dimensional woven veneer and manufacture process

A technology of three-dimensional weaving and manufacturing technology, which is applied in the direction of manufacturing tools, joining of wooden veneers, and wood layered products, and can solve the problem of affecting the strength and sensory quality of decorative panels, prone to cracks or displacement, and poor flatness and other issues to achieve the effect of ensuring sensory quality, good flatness, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

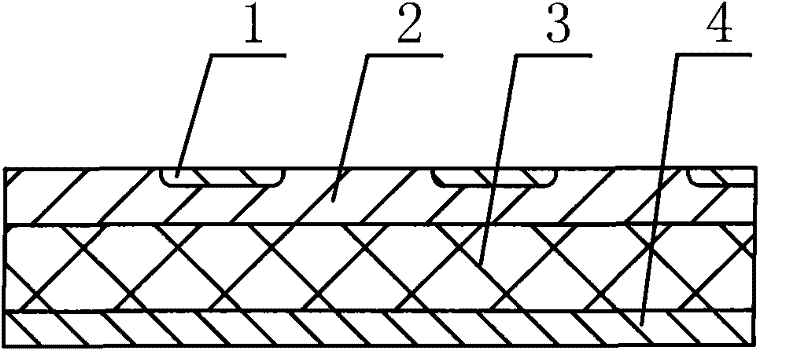

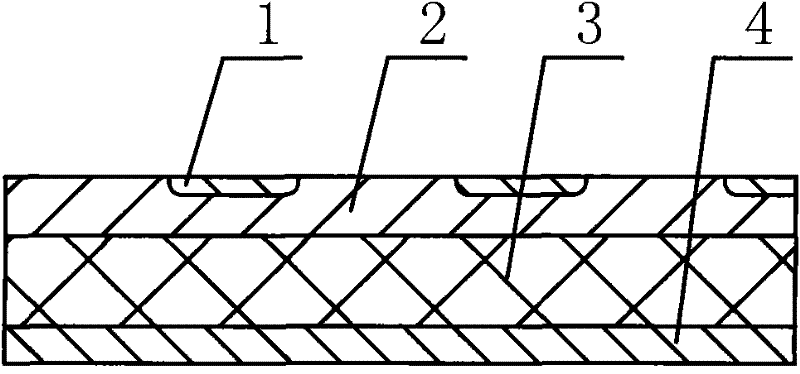

[0010] Embodiment 1: with reference to attached figure 1 . The three-dimensional weaving veneer includes a base plate 4, and the board surface of the base plate is composed of vertical veneer strips and horizontal veneer strips interlaced and pressed together to form a three-dimensional weaving veneer.

Embodiment 2

[0011] Embodiment 2: On the basis of embodiment 1, the width of described longitudinal veneer strip 1 and transverse veneer strip 2 is equal.

Embodiment 3

[0012] Embodiment 3: On the basis of Embodiment 1, the widths of the longitudinal veneer strip 1 and the transverse veneer strip 2 are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com