Grinding device for outer ring machining of drum brake assembly

A drum brake and brake technology, which is applied in the direction of grinding drive device, manufacturing tool, grinding frame, etc., can solve the problem of low braking pass rate, and achieve low pass rate, small braking torque and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. ,

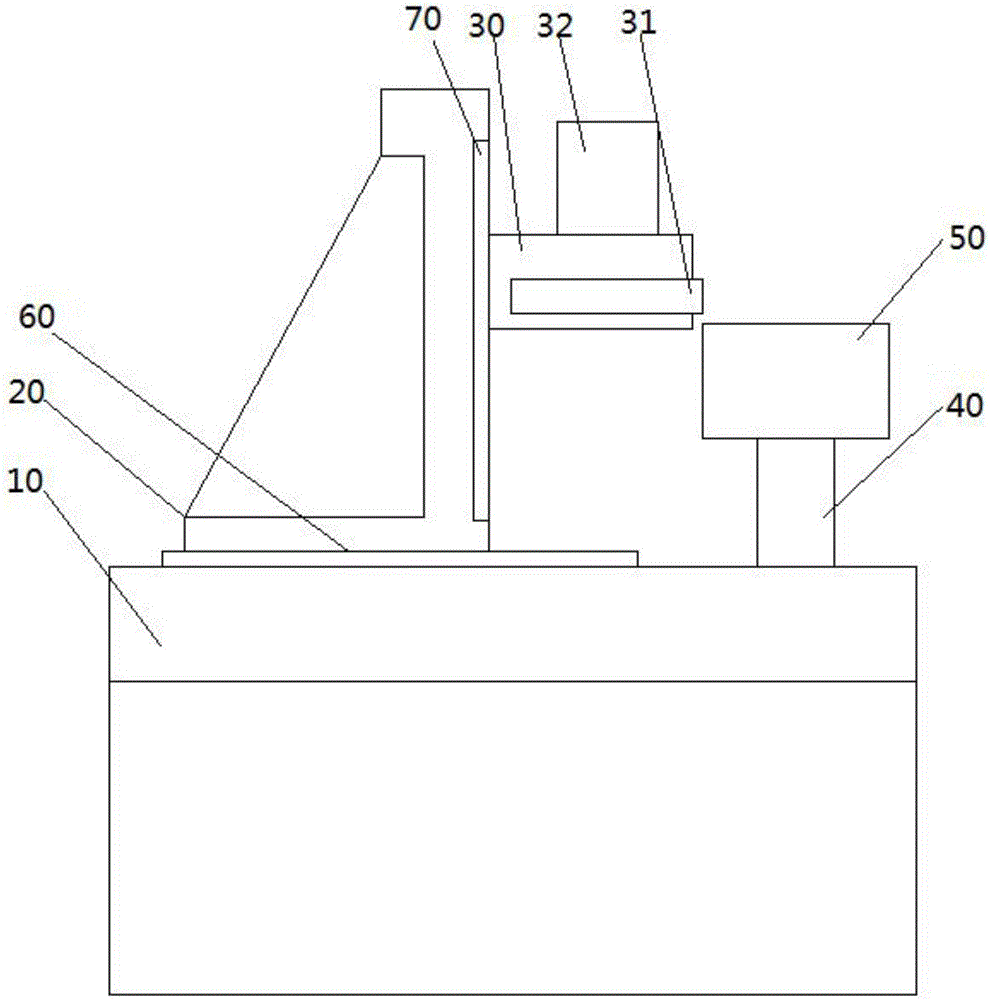

[0024] see figure 1 As shown, the present invention discloses a grinding device for cylindrical machining of a drum brake assembly, comprising a machine bed 10, a fixed support 20, a grinding disc 30, a motor (not shown) installed on the machine bed and The brake assembly 50 to be processed is arranged above the bed of the machine tool and opposite to the grinding disc.

[0025] A first V-shaped guide rail 60 is horizontally arranged on the machine tool bed 10, and the bottom of the fixed bracket 20 is installed in the first V-shaped guide rail 60, and can move forward and backward along the first V-shaped guide rail 60, thereby realizing the brake assembly to be processed. The adjustment of the radial dimension and the rapid advance and ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com