Automatic tapping equipment of wide-angle numerical-control uniflow meter

A numerically controlled, single-flow meter technology, applied in drilling/drilling equipment, metal processing equipment, reaming devices, etc., can solve the problems of different measurement accuracy, inconsistent measurement performance of single-stream heat meters, and watch case blanks The positioning reference cannot be guaranteed to be consistent, etc., to achieve the effect of ensuring consistency and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

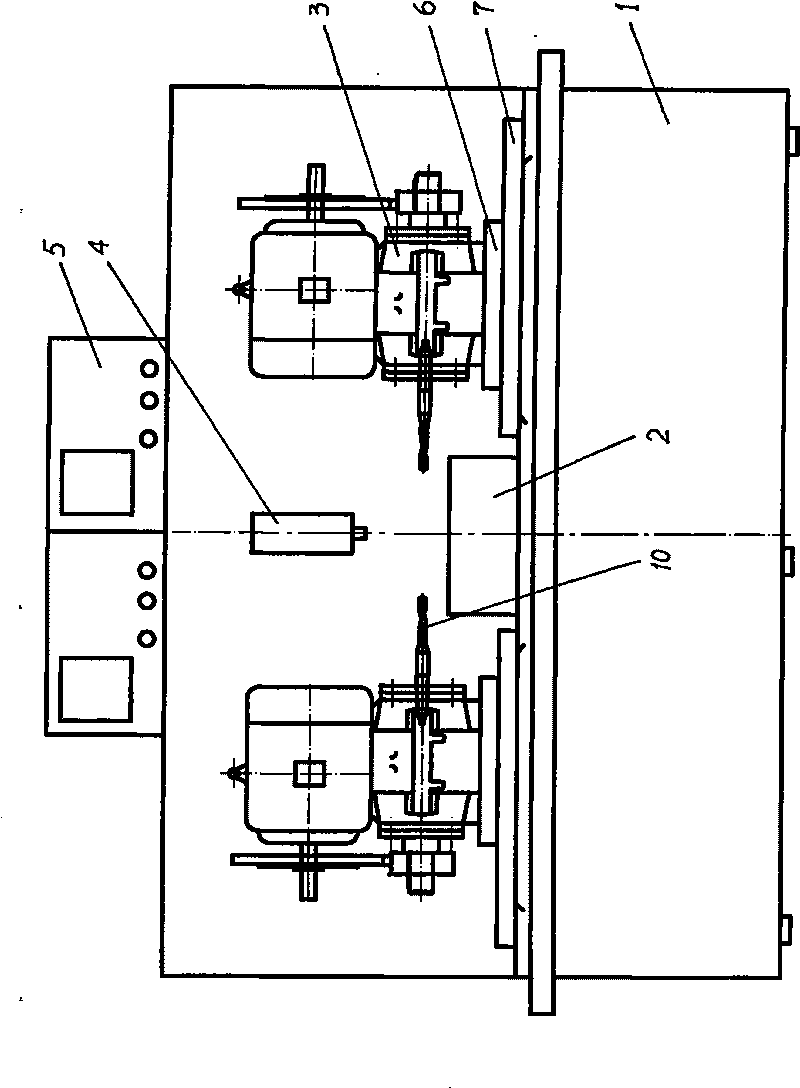

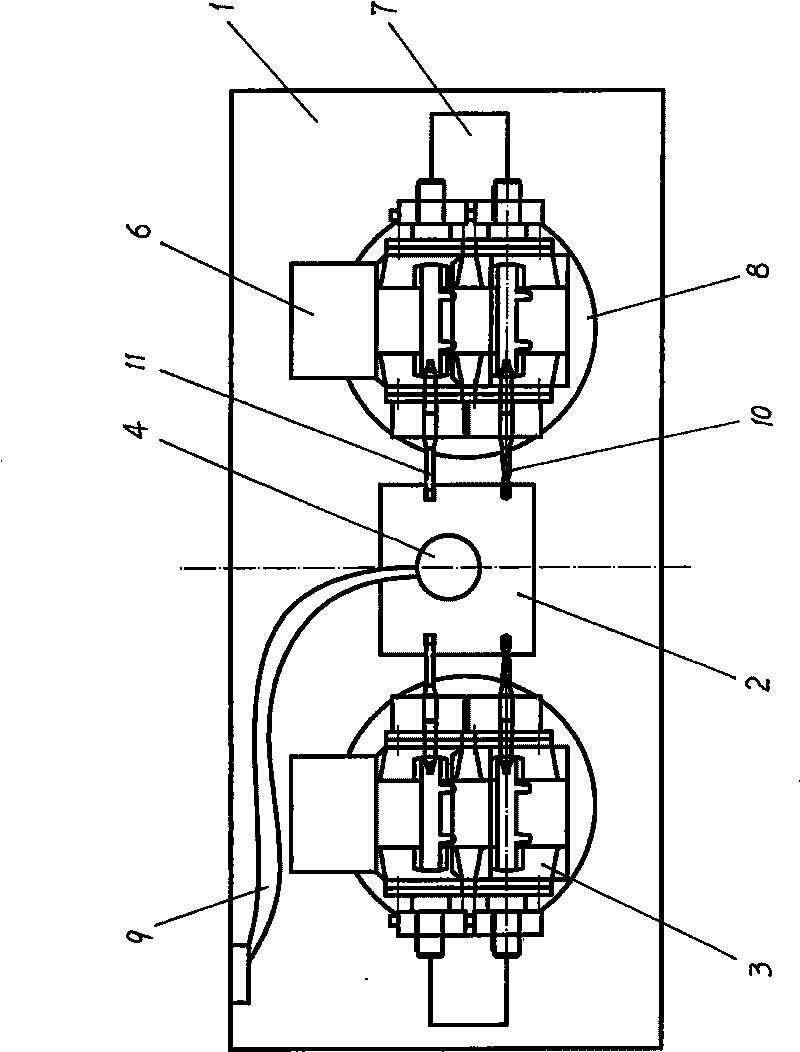

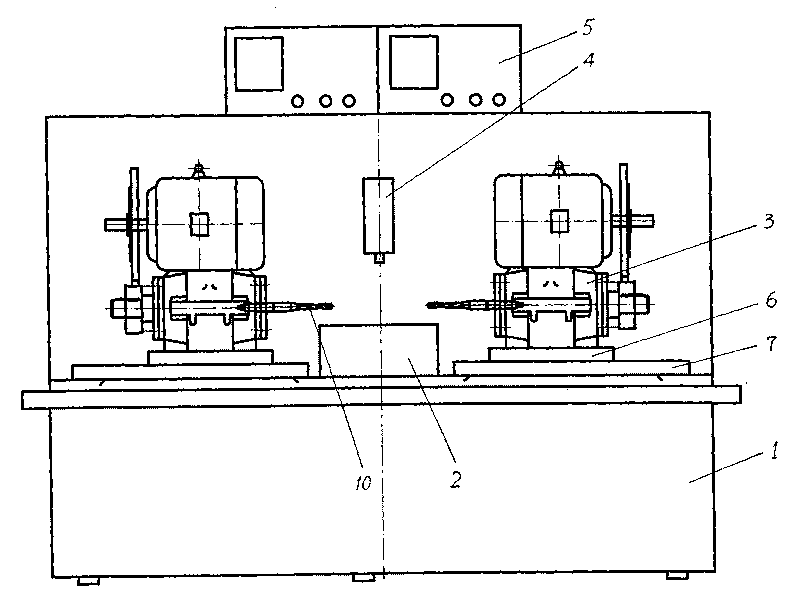

[0012] like figure 1 , figure 2 As shown, the present invention is provided with a rectangular bed 1, and a workbench 2 is installed in the center of the bed 1, and a watch case receiving groove is opened on the upper surface of the workbench 2 according to the shape of the watch case (not shown in the accompanying drawings) , the two opposite hole tubes on the case blank can extend symmetrically to both sides of the workbench. figure 1 Among them, a pneumatic clamping device 4 with a cylinder is arranged above the workbench 2, and a communication pipeline 9 is connected to the cylinder ( figure 2 ). Two power heads 3 are arranged on both sides of the workbench 2 respectively. The lower part of the power head 3 is provided with a horizontal slide rail 6 and a vertical slide rail 7 stacked up and down crosswise, so that the power head 3 can perform initial position adjustment in the front-rear direction and left-right direction and process feed. figure 2 Among them, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com