Transverse flux permanent magnetic motor and method for manufacturing stator thereof

A permanent magnet motor, transverse magnetic flux technology, applied in the manufacture of stator/rotor body, magnetic circuit static parts, magnetic circuit rotating parts, etc. Simple process and assembly, reducing motor volume and improving torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

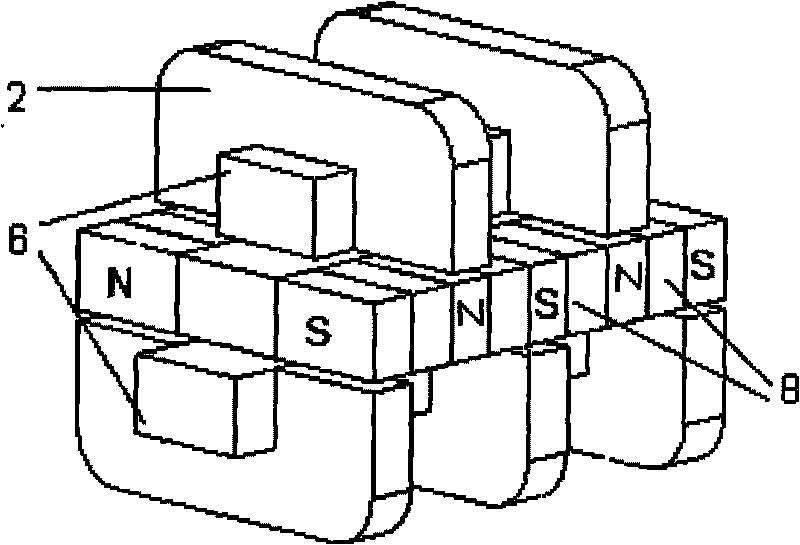

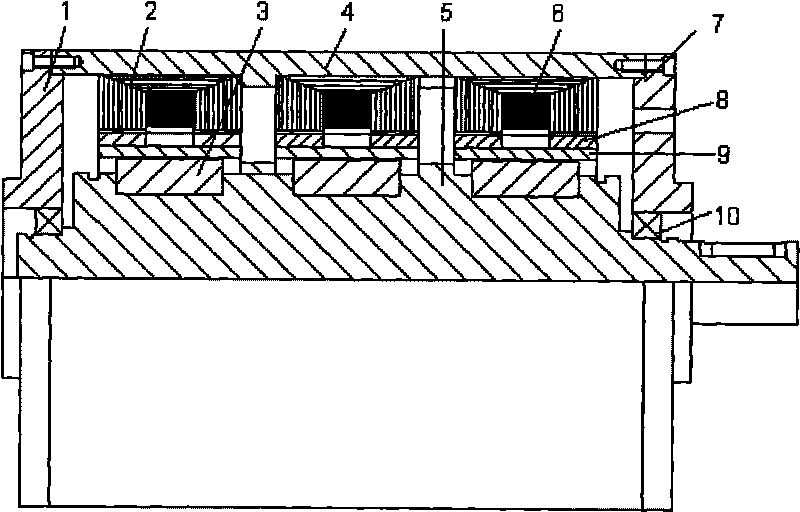

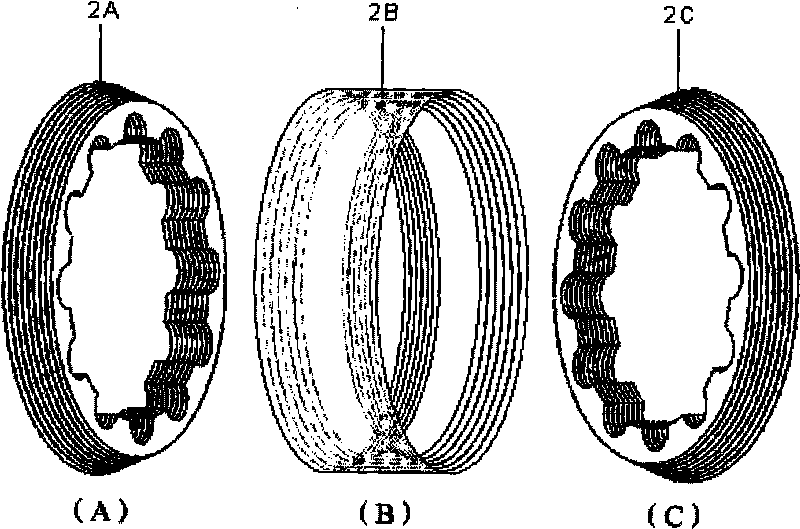

[0036] see figure 1 Introduce the structural characteristics of the transverse flux permanent magnet motor of the present invention: in the inside of the two side end covers 1 and 7 of the motor and the housing 4, the stator and the stator core 2 made of silicon steel sheets and the coil winding 6 are formed. A multi-phase electromagnetic induction component composed of a rotor composed of a rotor core 9 and a permanent magnet 8 is arranged axially along the motor shaft 5 of the motor, 10 is a motor bearing, and 3 is a keyway and a key. Among them, the stator core 2 of the motor is composed of left, middle and right parts (see image 3 with Figure 4 As shown), the joint surfaces of the three-part stator cores 2A, 2B, 2C are conical surfaces with the motor shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com