White spirit ageing process and device thereof

An aging device and liquor technology, which are applied in the field of liquor aging process and its devices, can solve the problems of large wine loss, substandard hygiene, long aging time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

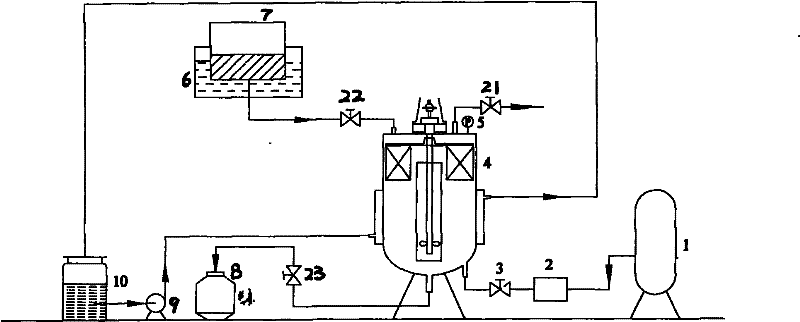

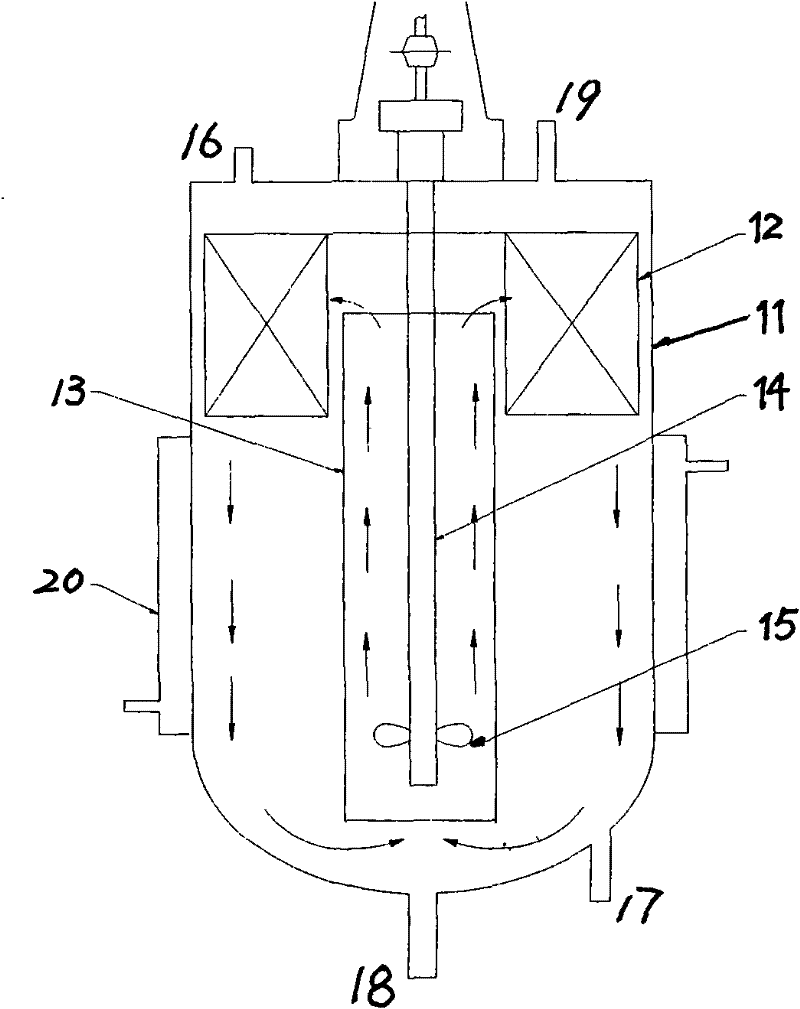

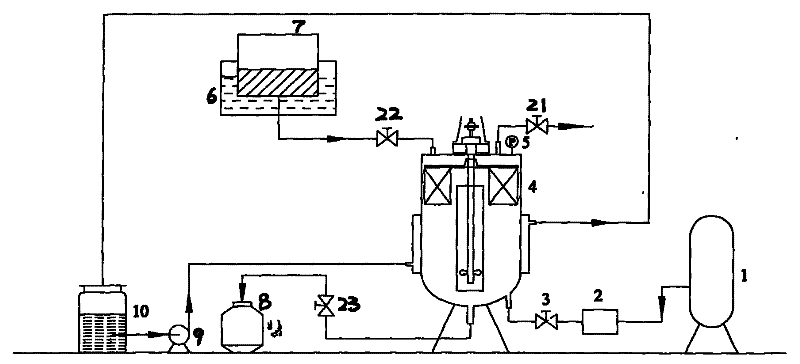

Method used

Image

Examples

Embodiment 1

[0027] Accelerate the aging of commercially available loose liquor, adjust the water bath to preheat the loose liquor to 20°C, adjust the temperature of the buffer tank and turn on the circulating water pump, maintain the temperature of the aging device at 20°C, inject new wine into the aging device, and open the air inlet and outlet valves , into the ozone, when the ozone concentration in the aging device reaches about 10mg / L, close the exhaust valve and continue to pass the ozone until the ozone pressure is 0.3MPa, open the aging device, and adjust the rotation speed of the rotary packing to 1500r / min through the variable speed regulator , process for 3 minutes, vent the gas, then pass ozone again until the ozone pressure is 0.3MPa, open the aging device, the speed is 1500r / min, treat for 40 minutes, cool the system temperature to below 20°C, open the liquid outlet valve, and the aged Liquor is sent to the wine storage tank. The aged loose wine basically has no loss of wine,...

example 2

[0031] To urge aging Fenyangwang new wine, adjust the water bath to preheat the loose wine to about 30°C, adjust the temperature of the buffer tank and turn on the circulating water pump, maintain the temperature of the aging device at about 30°C, inject the new wine into the aging device, open the exhaust valve, and Enter oxygen, after the oxygen concentration in the aging device is greater than 95% vol, close the exhaust valve and continue to pass oxygen until the oxygen pressure is 0.1MPa, open the aging device, adjust the rotation speed of the rotary packing to 1000r / min through the variable speed regulator, and process 5min, the gas is vented, and then oxygen is passed again until the oxygen pressure is 0.1MPa, the aging device is turned on, the rotation speed is 1000r / min, and the treatment is for 60min. To the wine storage tank. The loose wine aged by oxygen basically has no loss of wine, the total aldehydes are significantly reduced, the spicy taste is reduced, and the...

example 3

[0036] To urge aging Fenyangwang new wine, adjust the water bath to preheat the bulk wine to about 50°C, adjust the temperature of the buffer tank and turn on the circulating water pump, maintain the temperature of the aging device at about 50°C, inject new wine into the aging device, close the exhaust valve, and Enter sterile air until the air pressure is 0.2MPa, open the aging device, adjust the rotation speed of the rotary packing to 2000r / min through the variable speed regulator, process for 4min, vent the gas, and then pass sterile air again until the air pressure is 0.2MPa, open In the aging device, the rotation speed is 2000r / min, and the treatment is for 10 minutes, the temperature of the system is lowered to below 20°C, the liquid outlet valve is opened, and the aged liquor is sent to the wine storage tank. The loose wine aged by air basically has no loss of wine, the total aldehydes are significantly reduced, and the smell of new wine is obviously reduced. It has the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com