Micro-electromechanical microwave loss compensating microwave power detector

A technology of microelectronic machinery and microwave power, which is applied in the direction of electric power measurement, measuring device, generator/motor, etc. by thermal method, which can solve the problems affecting the accuracy of detection and the reduction of power to be measured without considering microwave loss, etc. To achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

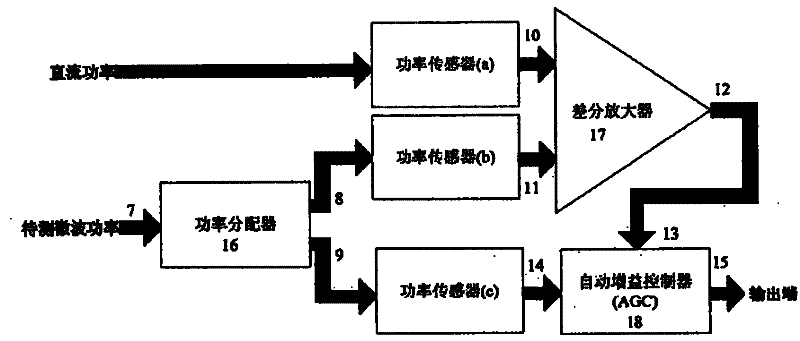

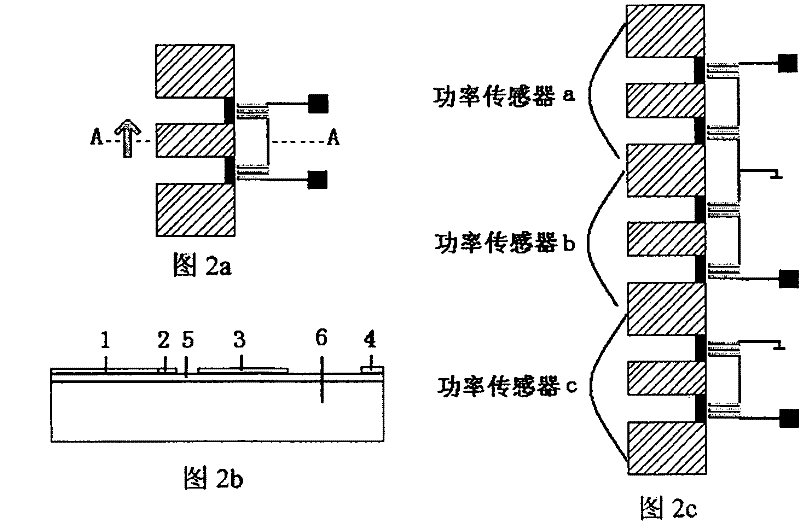

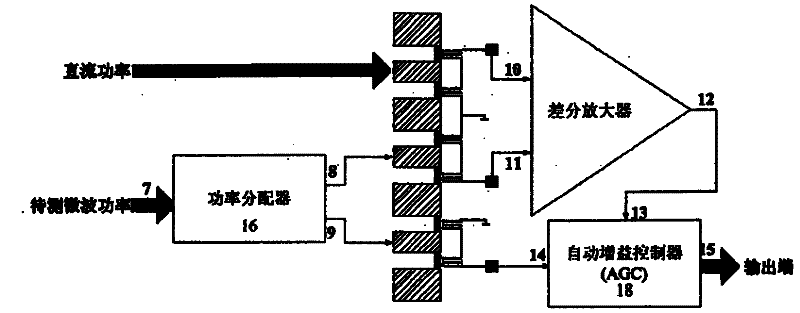

[0019] The MEMS microwave loss compensation type microwave power detection device of the present invention utilizes three completely identical power sensors and is supplemented by a power divider, a differential amplifier, and an automatic gain controller (AGC):

[0020] The microwave signal to be tested is added to the input terminal 7 of the power divider, and two completely identical microwave signals to be tested are generated at the first output terminal 8 of the power divider and the second output terminal 9 of the power divider, that is, the first one to be tested Microwave power P 1 and the second microwave power P to be measured 2 .

[0021] The microwave power sensor consists of three identical power sensors a, b and c. The output of power sensor a and power sensor b is connected to the two input terminals of the differential amplifier, and then the output of the differential amplifier is connected to the control terminal of AGC, thus forming the microwave power lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com